1 Food safety approach

1.1 Background

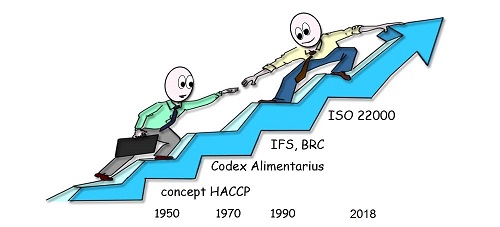

Evolution of food safety standards

Other food safety proverbs and quotes

The international standard ISO 22000 ("Food safety management systems - Requirements for any organization in the food chain") is recent (first edition in 2005) and allows for the harmonization and simplification of different approaches to the food safety management system (foodstuff) and to obtain certification by an accredited body.

Food: every product intended for nourishment

ISO 22000 is based on a global approach to the control of food safety and responds to the crisis of consumer confidence (BSE crisis, dioxin, bird flu).

The ISO 22000 standard has the long-term goal of replacing the many standards on food safety such as the IFS (International Food Standard) and the BRC (British Retail Consortium).

ISO comes from the Greek "isos" (equal).

In contrast to IFS and BRC, the ISO 22000 standard focuses on:

- the result requirements (management system) and not the means requirements (good hygiene practices)

- the entire food chain and

- a system approach (not limited to product categories)

Food hazard: potential harmful effect of a biological, chemical or physical nature on people’s health following the consumption of food

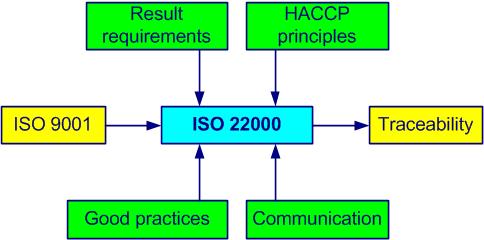

ISO 22000 is based on (see figure 1-1):

- the requirements of quality management systems (ISO 9001)

- guides to good hygiene practices

- hazard analysis principles (Hazard Analysis and Critical Control Point)

- effective internal and external communication

- an operational traceability system

Figure 1-1. ISO 22000 basics

The structures of the ISO 9001 and ISO 22000 standards are very close (high level common structure, annex SL), which facilitates the implementation of an integrated management system.

In the 1950s, Americans Edwards Deming and Joseph Juran contributed to the dissemination and use of methods of statistical quality control and continual improvementpermanent process allowing the improvement of the global performance of the organization (see also ISO 9000, 3.2.13 and ISO 14 001, 3.2) approach.

The HACCP concept emerged in the late 1950s when NASA (National Aeronautics and Space Administration) demanded safe food for astronauts. It was with the help of the company Pillsbury that the principles of the prevention of biological, chemical or physical hazards were put in place.

HACCP: Hazard Analysis Critical Control Point. System for the control of the hazards that threaten food safety

Food suitability: ensuring that food when consumed as intended, is acceptable to the consumer

Hazard analysis (food): way to determine the hazards and to establish the critical controls so as to guarantee food safety

These principles, later known as HACCP, significantly increase the safety of end products by controlling and inspecting processes and critical points as early and as efficiently as possible because, as the saying goes:

Prevention is better than cure

In 1993, the HACCP method was internationally recognized through its inclusion as an appendix in the Codex Alimentarius (Recommended International Code of Practice - General Principles of Food Hygiene, Rev.4, 2003) under the title Hazard Analysis Critical Control Points (HACCP) system and guidelines for its application. Note that the prerequisite for any HACCP system is the "classic" part of Codex, that is, good manufacturing and hygiene practices.

In 1993, the European Union also published a directive (93/43 / EC) based, among other things, on HACCP principles.

The Codex Alimentarius is a collection of hundreds of (Codex) standards, codes of practice, guidelines, procedure manual, recommendations, guides to good manufacturing and hygiene practices related to food safety and consumer protection. Use without moderation!

The food code (Codex Alimentarius) is the result of cooperation since the 1960s between FAO and WHO and can be found on the website: codexalimentarius

The requirementsexplicit or implicit need or expectation (see also ISO 9000, 3.1.2) for any company in the food chain are mainly focused around:

- the management system

- effective and interactive communication

- prerequisite programs

- HACCP hazard analysis principles

- traceability

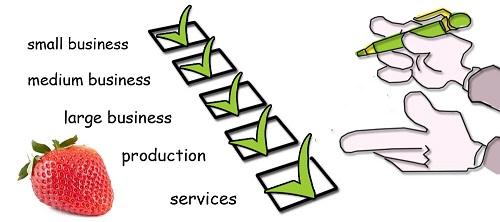

1.2 Scope

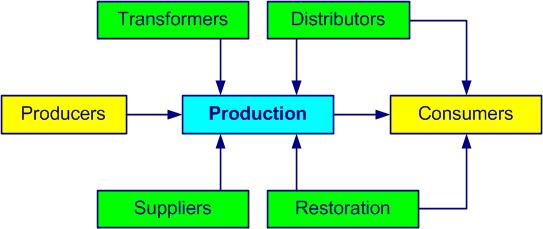

Scope of ISO 22000 and the food chain

The ISO 22000 standard is generic as it can be applied to any organizationa structure that satisfies a need (see also ISO 9000, 3.3.1) in the food chain, without limitations on size, activity or type. The food chain (cf. figure 1-2) includes:

- the original agricultural producers:

- animals

- vegetables

- food processors

- food processors for animals

- distributors (wholesalers and retailers) of food products

- restoration

- providers of services and materials:

- storage, transportation

- equipment

- packaging

- pesticides, veterinary drugs

- additives and ingredients

- hygiene and cleaning products

- various services

Figure 1-2. The food chain

Some advantages of the ISO 22000 food safety management system:

- a common and complete system for the entire food chain

- greater assurance to:

- produce and distribute only products that are safe for the consumer

- comply with statutory and regulatory requirements

- communicate in full transparency with interested parties

- improved customer satisfaction related with its requirements

- staff awareness of food safety hazards

- staff involvement in the continual improvement approach

- internal decompartmentalization

- an introduction only of useful measures

- a hazard analysis for any control measure

- a focus on essential hazards

- a controlled analysis of hazards

- risk-based thinking (risk-based approach)

- up-to-date documentation

- a guarantee of consistency between the declared food safety policy and the practices in the field

1.3 Steps

ISO 22000 preparation and implementation, Deming cycle

A well-prepared approach is halfway to success

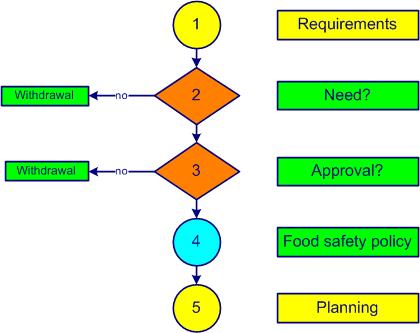

The approach to implementing a food safety management system (FSMS) goes through several steps. An example of preparation is shown in figure 1-3.

Figure 1-3. FSMS preparation

Step 1 involves identifying the needs and expectations (requirementsexplicit or implicit need or expectation (see also ISO 9000, 3.1.2)) of customers (internal and external). The involvement of top management at its highest level is truly indispensable. The advice of a consultant is often solicited. Determining the current status of the management system (whole or partial) would be welcome at this stage. An external certification body is chosen.

One of the key questions that comes up quickly (step 2) is the need for this decision. If this is not really necessary or if the estimated costs of the certification approach exceed the available resources, it is better to reject this idea immediately.

The benefits of implementing a food safety management system are often:

- an improved image of the company

- being one step ahead of the competition

- valued good practices

- prevention of food safety becomes routine

- better economic results

- lower manufacturing costs

- staff who are aware, consulted, motivated and proud

- profitable engagement for all

- formalization of knowledge

- updated legal obligations

The benefits of the certification of a food safety management system are often:

- new customers

- increased market share

- an increase in sales

- better financial performance

More than one and a half million businesses worldwide cannot be wrong!

Danone, one of the world leaders in the food industry, has implemented ISO 22000 to guarantee the food safety of its products and improve consumer confidence. The standardization of procedures and the establishment of a food safety culture have made it possible to reduce the risks of contamination and improve product traceability.

Danone recorded significant improvement in food safety and risk management, demonstrating the company's commitment to consumer protection and the effectiveness of its food safety management system.

The internalization of the spirit of the principles and requirementsexplicit or implicit need or expectation (see also ISO 9000, 3.1.2) of an ISO standard significantly improves the overall performance of your business, especially when it is not considered as a constraint.

The third step shall determine whether this approach receives the approval of the staff. A communication campaign is launched in-house on the objectives of a food safety management system (FSMS). The staff is aware and understands that, without their participation, the project cannot succeed.

Have confidence: success will come with the involvement and effort of all!

The vision (what we want to be), the mission (why we exist) and the business plan of the company are determined. The following step (4) includes the establishment of an outline of the food safety policy and objectives. If you do not have a copy of the ISO 22000 standard, now is the time to get it (cf. section of the present course).

Planning is the last step (5) of the project preparation for obtaining ISO 22000 certification. A reasonable period is between 5 to 8 months (each company is unique and specific). A top management representative is appointed as food safety project leader. Top management confirms the financial resources and staff. Team training on the requirementsexplicit or implicit need or expectation (see also ISO 9000, 3.1.2) of ISO 22000 is planned. Top management commitment is formalized in a document communicated to all staff.

The establishment and implementation of an ISO 22000 food safety management system are shown in figure 1-4 and in annex 01.

.jpg)

Figure 1-4. FSMS implementation

Step 1 aims to identify and determine the processes, interactions, owners, responsibilities and drafts of certain documented information. The first versions of processactivities which transform inputs into outputs (see also ISO 9000, 3.4.1) sheets, job descriptions and work instructions are written with the participation of the maximum number of available persons. The basics of internal and external communication are established.

In step 2 prerequisite programs are selected as principles and good manufacturing and hygiene practices related to hazards (biological, chemical, physical).

Step 3 identifies the issues and sets objectives from the food safety policy. Control measures are identified and classified. Training of internal auditors is taken into account.

Hazard control is done in step 4. The operational prerequisite programs (oPRPs) are established and the HACCP plan is introduced. A traceability systemset of interacting processes (see also ISO 9000, 3.2.1) is proposed. Internal audits help to evaluate the degree of implementation of the systemset of interacting processes (see also ISO 9000, 3.2.1).

A first encounter with the tools and application areas of continual improvementpermanent process allowing the improvement of the global performance of the organization (see also ISO 9000, 3.2.13 and ISO 14 001, 3.2) is made in step 5. A table with the main costs of obtaining quality (COQcosts of obtaining quality) is filled in by those with the information at hand. Risks are determined, actions are planned and opportunities for improvement are found. An approach to preventing nonconformities and eliminating causes is established. The internal and external communication is established and formalized.

To conduct the pre-audit of the FSMS (step 5), documented information and best practices are checked and approved by the appropriate people. A management review allows evaluation of compliance with applicable requirementsexplicit or implicit need or expectation (see also ISO 9000, 3.1.2). The food safety policy and objectives are finalized. A food safety manager from another company or a consultant can provide valuable feedback, suggestions and recommendations. Gaps are corrected.

When the systemset of interacting processes (see also ISO 9000, 3.2.1) is accurately implemented and followed, the certification of the FSMS by an external body is a breeze, a formality (step 6).

An appropriate method for evaluating the performance of your food safety management system is the RADAR logic model of excellence EFQM (European Foundation for Quality Management) with its nine criteria and overall score of 1000 points.

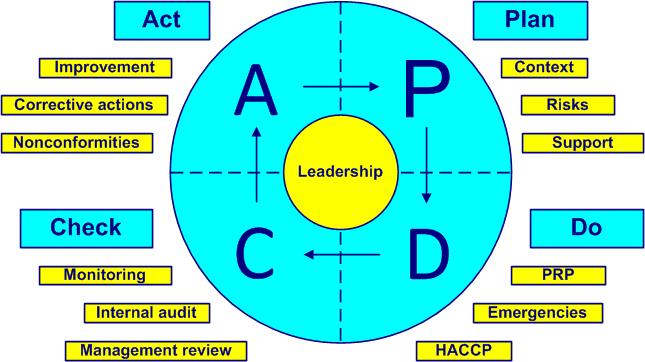

The Deming cycle (figure 1-5) is applied to control any process. The PDCA cycles (Plan, Do, Check, Act) are a universal base for continual improvement.

Figure 1-5. The Deming cycle

- Plan – define context, define and establish policy, objectives, resources, documentation, plan actions to address risks and demonstrate leadership (ISO 22000 clauses 4, 5, 6 and 7)

- Do – implement operational control, prerequisites programs, traceability, respond to emergencies, control hazards, inspection, control nonconformities and demonstrate leadership (ISO 22000 clause 8)

- Check – inspect, analyze and evaluate, conduct process audits, audit the HACCP plan, conduct management review and demonstrate leadership (ISO 22000 clause 9)

- Act – adapt, improve, update the FSMS, react with corrective actions, find new improvements (new PDCA cycle) and demonstrate leadership (ISO 22000 clause 10)

For more information on the Deming cycle and its 14 points of management theory, you can consult the classic book "Out of the Crisis", W. Edwards Deming, MIT press, 1982.