4 Context .gif)

4.1 The organization and its context

External and internal issues that can influence the EnMS

Requirements 1 to 2 (see also the quiz)

The two most important things in a company do not appear in its balance sheet: its reputation and its people. Henry Ford

To successfully implement an energy management systemset of processes allowing energy objectives to be achieved, we must understand and evaluate everything that can influence the reason for being and business performancemeasurable and expected results of the management system (see also ISO 9000, 3.7.8). You should think carefully about a few key activities:

- develop a thorough diagnosis of the unique context in which your company exists, taking into account:

- external issues such as theenvironment like:

- social

- regulatory, standards, regulations

- economic, energy costs

- technological, energy types

- restrictions on energy supply, security and reliability

- effects of weather conditions

- effects of climate change

- effects of greenhouse gas (GHG) emissions

- energy costs

- availability of energy types

- regulatory

- internal issues like:

- specific aspects of the corporate culture:

- vision

- rationale, purpose and mission

- core values, sustained development

- personnel

- products and services

- infrastructure

- mastery of energy management

- mastery of existing technology

- asset management plans

- contingency plans in the event of energy supply interruption

- financial resources

- operational risks

- specific aspects of the corporate culture:

- external issues such as theenvironment like:

- monitor and review regularly any information relating to external and internal issues

- analyze the factors that may influence the achievement of business objectives

- determine whether issues arise from climate change

The SWOT and PESTEL analyses can be useful for relevant analysis of business context (cf. annex 05).

An example of a SWOT analysis is shown in figure 4-1:

|

Internal factors |

|

|

Strengths |

Weaknesses |

|

|

|

External factors |

|

|

Opportunities |

Threats |

|

|

Figure 4-1. Energy SWOT analysis

A list of external and internal issues is carried out by a multidisciplinary team. Each issue is identified by its level of influence and control. Priority is given to issues with great influence and poor control.

An ISO 50001-certified company is facing new requirements from its major customers, who are requesting detailed reports on the carbon footprint and energy efficiency of its supply chain. The company's current energy management system (EnMS) does not address these new requirements, and management is concerned about losing its contracts.

The energy manager organizes a meeting with the sales department and management to understand the new customer expectations. The EnMS is updated to include these new requirements in the list of relevant issues. Energy performance indicators are established to measure the carbon footprint, and this information is communicated to customers.

.jpg) Minute of relaxation. Game: Context of the company

Minute of relaxation. Game: Context of the company

- diagnosis of the context includes the main external and internal issues

- the core values as part of the corporate culture are taken into account in the context of the company

- the results of the context analysis are widely diffused

- the SWOT analysis includes many relevant examples

- the SWOT analysis is a powerful tool for identifying the main threats and opportunities

- the issues of the context of the company, such as the competitive environment, are not taken into account

- in some cases, the corporate culture is not taken into account

- risk analysis does not take into account strategic issues

- no clear link between the SWOT analysis and the actions undertaken

4.2 Stakeholders

Understand the requirements of stakeholders

Requirements 3 to 9

There is only one valid definition of a business purpose: to create a customer. Peter Drucker

To understand the needs and expectations of stakeholdersperson, group or organization that can affect or be affected by a company (see also ISO 26000, 2.20), we must begin by determining those who may be affected by the energu management system such as:

- employees

- customers

- external providers

- owners

- shareholders

- bankers

- distributors

- competitors

- citizens

- neighbors

- social and political organizations

A list of stakeholdersperson, group or organization that can affect or be affected by a company (see also ISO 26000, 2.20) is created by a multidisciplinary team. Every stakeholderperson, group or organization that can affect or be affected by a company (see also ISO 26000, 2.20) is determind by its level of influence and control. Priority is given to stakeholdersperson, group or organization that can affect or be affected by a company (see also ISO 26000, 2.20) with great influence and poor control.

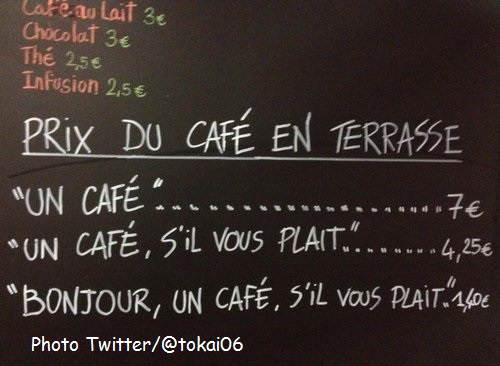

The customer is king but we still can fight against rudeness. This example is from the restaurant La petite Syrah in Nice and its coffee prices:

“A coffee”...................................7 €

“A coffee, please”...............4,25 €

“Hello, a coffee, please”....1,40 €

Anticipating the reasonable and relevant needs and expectations of stakeholdersperson, group or organization that can affect or be affected by a company (see also ISO 26000, 2.20) involves:

- meeting the legal and other requirements applicable to the EnMS

- meeting the requirements of the product or service offered

- preparing to address risks

- finding improvement opportunities

When a requirementexplicit or implicit need or expectation (see also ISO 9000, 3.6.4) is accepted, it becomes an internal requirementexplicit or implicit need or expectation (see also ISO 9000, 3.6.4) of the EnMSEnergy management system.

Fot more details on compliance management see the ISO 37301 standard (see § 2.1).

"In a typical company, if you have a meeting, no matter how important, there is always a part that is not represented: the customer. It is very easy within the company to forget the customer." Jeff Bezos.

To address this concern, it became customary to place an empty chair at every meeting.

- the list of stakeholders is updated

- the needs and expectations of stakeholders are established through meetings on-site, surveys, roundtables and meetings (monthly or frequent)

- the application of statutory and regulatory requirements is a prevention approach and not a constraint

- regulatory and legal requirements are not taken into account

- regulatory monitoring activities are not carried out regularly

- delivery times are not validated by the customer

- stakeholder expectationss are not determined

- the list of stakeholders does not contain their area of activity

4.3 Scope

Define the scope of the EnMS

Requirements 10 to 15

In many areas, the winner is the one who is best informed. André Muller

The scope (or in other words, the perimeter) of the energy management systemset of processes allowing energy objectives to be achieved is defined. When a requirementexplicit or implicit need or expectation (see also ISO 9000, 3.6.4) cannot be applied, a justification is included in the procedure that is maintained, cf. annex 20.

The specific context of the company is taken into account to determine the scope of the EnMSEnergy management system including:

- issues (cf. sub-clause 4.1)

- products and services

- corporate culture

- environment:

- social

- financial

- technology

- economic

- requirements of stakeholders (cf. sub-clause 4.2)

- outsourced processes

An industrial group has decided to implement an ISO 50001 energy management system (EnMS). The group has several production plants, logistics warehouses, and a head office with offices. Top management is unsure whether to include all sites in the ISO 50001 certification or to start with a single pilot site to facilitate implementation.

Top management decides to start with a production site that has high energy consumption and a motivated workforce. This pilot site will serve as a model for the others. The energy team focuses on this site, implementing the standard in its entirety. Once certification is obtained, best practices are shared with the other sites to facilitate a gradual rollout.

- the scope is relevent and available upon request

- non applicable requirements are justified in writing

- some products are outside the scope of the EnMS without justification

- the paint shop is not included in the scope of the EnMS

- the scope is obsolete (a new subsidiary is not included)

4.4 EnMS and its processes

EnMS requirements, processes and interactions

Requirements 16 to 17

Quality management, in its essence, concerns the description of processes and their improvement. Isaac Getz

The requirementsexplicit or implicit need or expectation (see also ISO 9000, 3.6.4) of the ISO 50001 standard include the:

- EnMS

- energy performance

- control of business processes

- continual improvement

To do this:

- the energy management system is:

- established

- documented (a simple and sufficient documentation system is set up)

- implemented and

- continually improved

- the energy policy, objectives, resources and the work environment are determined

- threats are determined and actions to reduce them are established (cf. sub-clause 6.1)

- the core necessary EnMS processes are controlled:

- corresponding resources are ensured

- the inputs and outputs are determined

- the necessary information is available

- owners are appointed (responsibilities and authorities defined)

- sequences and interactions are determined

- each process is measured and monitored (established criteria)

- objectives are set and performance indicators analyzed

- process performance is evaluated

- necessary changes are implemented to achieve the expected results

- actions to obtain the continual improvement of processes are established

- audits and reviews of the EnMS are performed regularly

- the necessary minimum ("as much as needed") of documentation on the processes is maintained and retained (

)

)

The energy manual is not a requirementexplicit or implicit need or expectation (see also ISO 9000, 3.6.4) of ISO 50001 version 2018, but it is always a possible method to present the companya structure that satisfies a need, its EnMSEnergy management system and its proceduresdocument describing the to carry out a process (see also ISO 9000, 3.4.5 and documented information) and processesactivities that transform inputs into outputs (see also ISO 9000, 3.4.1) (cf. annex 07).

The ISO guide “The integrated use of management system standards” of 2018, contains relevant recommendations on the integration of management systems.

.jpeg) Pitfalls to avoid:

Pitfalls to avoid:

- going overboard on quality:

.jpg)

- a useless operation is performed without adding value and without the customer asking for it - it is a waste, cf. quality tools D 12

- having all procedures written by the energy manager:

.jpg)

- energy is everybody's business, "the staff is conscious of the relevance and importance of each to the contribution to energy objectives", which is even more true for department heads and process owners

- forgetting to take into account the specificities related to the corporate culture:

.jpg)

- innovation, luxury, secrecy, authoritarian management (Apple)

- strong culture related to ecology, action and struggle, while cultivating secrecy (Greenpeace)

- fun and quirky corporate culture (Michel & Augustin)

- liberated company, the man is good, love your customer, shared dream (Favi), cf. the course T 60

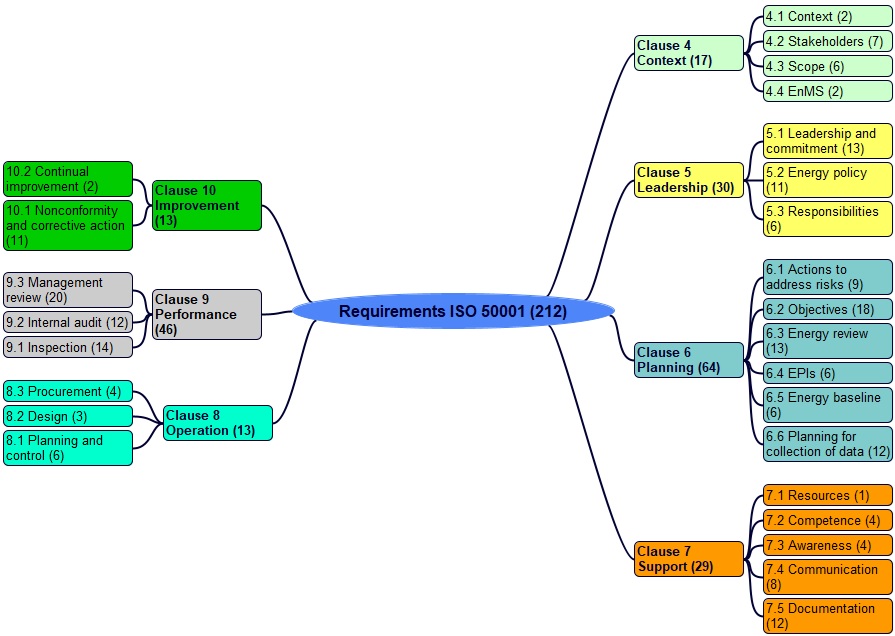

The requirements of the ISO 50001 standard are shown in figures 4-1:

Figure 4-1. The requirements of the ISO 50001:2018 standard

A company is already ISO 9001 (Quality) and ISO 14001 (Environment) certified. Top management now wants to obtain ISO 50001 certification, but is concerned about the administrative burden. It is wondering whether it should create a separate energy management system (EnMS) or whether it can be integrated with its existing systems to reduce bureaucracy.

The quality and environment manager identifies the commonalities between the three standards (common structure, risk management, corrective actions, management review, internal audits). Existing procedures are updated to include the requirements of ISO 50001. For example, the management review is modified to include a focus on energy performance.

This highly effective approach reduces duplication of work. Systems integration makes management simpler, more consistent, and less bureaucratic.

- the process map has enough arrows to show who is the customer (internal or external)

- for a process, it is better to use a lot of arrows (several customers) rather than to forget one

- reveal the added value of the process during the process review

- the analysis of processes performance is an example of continual improvement evidence of the effectiveness of the EnMS

- top management regularly monitors the objectives and action plans

- the purpose of each process is clearly defined

- some process outputs are not set correctly (customers not considered)

- process effectiveness criteria are not established

- the process owners are not formalized

- outsourced processes are not determined

- control of outsourced services is not described

- sequences and interactions of certain processes are not determined

- criteria and methods for ensuring effective processes are not determined

- monitoring the effectiveness of certain processes is not established

- the EnMS resources do not allow achievement of energy objectives

- the EnMS is not updated (new processes are not determined)

- the threats and weaknesses identified in the SWOT analysis remain without actions