1 Energy approach

1.1 History

History of energy standards

Energy consumption worldwide continues to grow. It will likely double in the next decade.

Among other things, energy is the main cause of climate change and contributes significantly to the production of greenhouse gas (GHG) emissions.

The International Organization for Standardization (ISO) was founded in 1947. ISO comes from the Greek "isos" (equal). The first energy management systemset of processes allowing energy objectives to be achieved standards date back to the early 2000s:

- ANSI/MSE 2000, A Management System for Energy, USA, 2000

- DS 2403, Energy Management – Specification, Denmark, 2001

- SS 627750, Energy Management System, Sweden, 2003

- IS 393, Energy Management Systems - Requirements With Guidance For Use, Ireland, 2005

- BP X30-120: Energy Diagnostics in Industry, France, 2006

- Directive 2006/32/EC on Energy End-Use Efficiency and Energy Services, EU, 2006

- UNE 216301, Energy management system. Requests. Spain, 2007

- KSA 4000, South Korea, 2007

- GB/T 2331, China, 2009

- EN 16001, Energy Management Systems - Requirements with Implementation Guidance, Sweden, 2009

- SANS 879, South Africa, 2009

- Directive 2009/28/EC on the Promotion of Renewable Energy

- FD CEN/CLC/TR 16103, Energy Management and Energy Efficiency - Glossary of Terms, France, 2010

- EN 15900, Energy Efficiency Services - Definitions and Requirements, Italy, 2010

- ISO 50001, Energy Management Systems - Requirements with Implementation Guidance, 2011

- EN 16212, Energy Efficiency and Savings Calculation: Top-Down and Bottom-Up Methods, 2012

- EN 16231, Energy Efficiency Benchmarking Methodology, 2012

- SOR/94-651, Energy Efficiency Regulations, Canada, 2013

- FD X 30 147, Measurement Plan for Monitoring Energy Performance, 2015

- FD X30 148, Energy Performance Measurement and Verification: Good Practices for Calculating Energy Savings, 2016

- ISO 17743, Definition of a Methodological Framework for Calculating and Reporting Energy Savings, 2016

- ISO 50001, Energy Management Systems — Requirements with Guidance for Implementation, 2018

- EN 17267, Measurement Plan and Energy Monitoring, 2019

- IPMVP (International Performance Measurement and Verification Protocol), 2019

- NF EN 16247-1, Energy Audits - Part 1: General Requirements, 2022

1.2 Implementation

Implementation, energy performance, components, activities

The ISO 50001 standard is generic because it applies to the energy management systemset of processes allowing energy objectives to be achieved of any companya structure that satisfies a need, regardless of size, activity, or type. It is an international voluntary standard that allows certification by an accredited (certification) body.

More than a standard, ISO 50001 is an ongoing management commitment to energy effectiveness, environmental responsibility and sustainable development. This commitment requires a long-term investment of time and resources.

The standard does not set energy performancemeasurable result of energy consumption, use and effectiveness objectivesmeasurable goal to be achieved.

All energy sources are covered: electricity, fuel, natural gas, steam, heat, compressed air, etc.

No distinction should be made between renewable and other energy sources.

The international unit of measurement for energy is the joule (J).

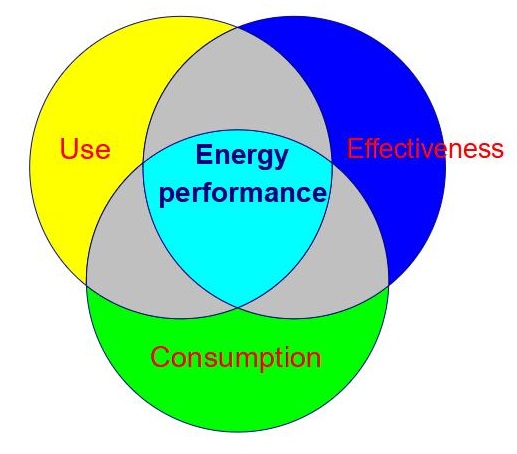

Energy performancemeasurable result of energy consumption, use and effectiveness comprises three distinct components, the measurable results of which are shown in figure 1-1:

Figure 1-1. Components of energy performance

Energy use includes, for example:

- powering production lines

- heating

- lighting

- ventilation

- cooling

- transportation

- processing

Energy effectivenesscapacity to perform planned activities with minimum effort (see also ISO 9000, 3.7.11) is, for example, the ratio between the energy required and the energy consumed.

Reference consumption serves as a quantified basis for comparing energy performancemeasurable result of energy consumption, use and effectiveness.

The ISO 50001 standard enables activities such as:

- establishing an energy policy

- defining energy objectives and targets

- analyzing energy performance

- making fact-based decisions

- monitoring and measuring performance

- evaluating results

- assessing compliance with legal requirements

- continually improving your EnMS

1.3 Principles and steps

Quality management principles, preparation and implementation, Deming cycle

Energy performance is a journey, not a destination

The energy approach is a mindset that begins with top managementgroup or persons in charge of the organizational control at the highest level (see also ISO 9000, 3.1.1) as a strategic decision and extends to all staff. Top managementgroup or persons in charge of the organizational control at the highest level (see also ISO 9000, 3.1.1) develops an energy policy, which sets objectivesmeasurable goal to be achieved that are applicable to all activities. The tool used to achieve these objectivesmeasurable goal to be achieved is the energy management systemset of processes allowing energy objectives to be achieved (EnMSEnergy management system). Optimizing daily energy consumption is the essential concept of the EnMSEnergy management system.

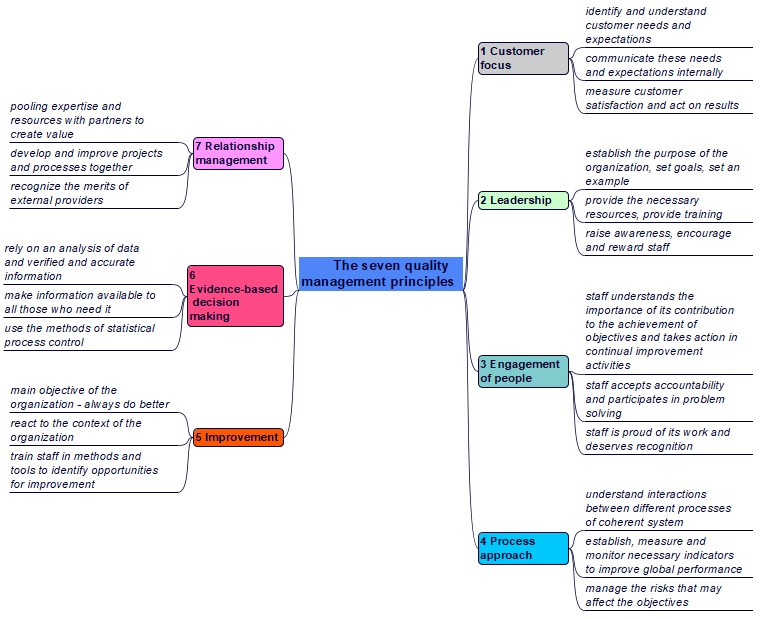

The seven qualityaptitude to fulfill requirements (see also ISO 9000, 3.6.2) management principles (see figure 1-2) will help us achieve sustainable performance (see ISO 9000:2015, § 2.3). Previously, there were eight principles, but now the system approach is integrated into the process approachmanagement by the processes to better satisfy customers, improve the effectiveness of all processes and increase global efficiency (see also ISO 9001, 03).

Figure 1-2. The 7 quality management principles

A well-prepared approach is half successful

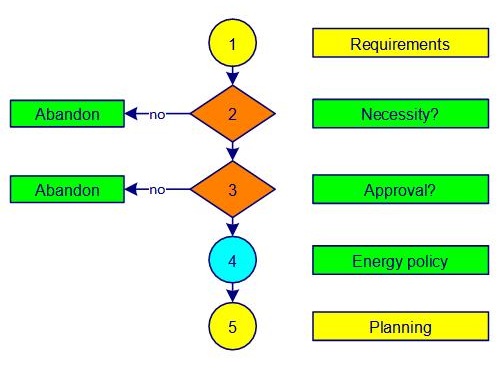

The approach to implementing an energy management systemset of processes allowing energy objectives to be achieved starts with the preparation. An example is shown in figure 1-3.

Figure 1-3. QMS preparation

Step 1 involves identifying the needs and expectations (requirements) of stakeholdersperson, group or organization that can affect or be affected by a company (see also ISO 26000, 2.20)

- staff

- customers, consumers

- competitors

- stakeholders, investors

- external providers (suppliers, subcontractors, partners)

- organizations and branch associations

- statutory and regulatory authorities

The involvement of top managementgroup or persons in charge of the organizational control at the highest level (see also ISO 9000, 3.1.1) at its highest level is truly indispensable. The advice of a consultant is often solicited. Determining the current status of the management systemset of processes allowing objectives to be achieved (see also ISO 9000, 3.5.3) (whole or partial) would be welcome at this stage. An external certification body is chosen.

One of the key questions that comes up quickly (step 2) is the need for this decision. If this is not really necessary or if the estimated costs of the certification approach exceed the available resources, it is better to reject this idea immediately.

The ISO 9000 family of standards will stop you making promises you can't fulfil and help you keep those you can. David Hoyle

The benefits of implementing an energy management systemset of processes allowing energy objectives to be achieved are often:

- an improved image of the company

- being one step ahead of the competition

- establish energy performance inspection and analysis activities

- be recognized as an environmental protection player

- unite staff around environmental protection

- promote greenhouse gas emission reduction projects

- reduce its ecological footprint

- facilitate communication on energy resource management

- foster a corporate culture based on efficiency and innovation

- apply innovations to make processes less energy-intensive

- prioritize the implementation of new high-energy performance technologies

- achieve a rapid return on investment

- provide a framework for improving energy efficiency

- ensure the company's sustainability

- optimize energy effectiveness throughout the supply chain

- make decisions based on relevant data

- promote best practices in energy consumption

- continuously seek to improve energy efficiency

- reduce its energy bills

- raise awareness and involve staff who are consulted, motivated and proud

- keep its legal obligations up to date

The benefits of the certification of an energy management systemset of processes allowing energy objectives to be achieved are often:

- new customers

- increased market share

- better financial performance because energy management is synonymous with efficiency and therefore, saving

More than one and a half million businesses worldwide can not be wrong!

The Hilton Group, one of the world's largest hotel chains, was the first company in the industry to obtain ISO 50001 certification for its entire portfolio. This was achieved after a complete overhaul of its system for measuring the group's performance.

The Hilton Group achieved significant savings, reducing its energy intensity by 20.6% and its carbon intensity by 30%.

"ISO 50001 has helped us validate the consistency of our energy management approach across all our properties. Since implementing the standard, energy management has remained a key focus for our management, and we continue to seek opportunities to further improve our performance." Maxime Verstraete, Vice President

The internalization of the spirit of the principles and requirementsexplicit or implicit need or expectation (see also ISO 9000, 3.6.4) of an ISOInternational Organization for Standardization standard significantly improves the overall performancemeasurable and expected results of the management system (see also ISO 9000, 3.7.8) of your business, especially when it is not considered as a constraint.

The third step shall determine whether this approach receives the approval of the staff. A communication campaign is launched in-house on the objectivesmeasurable goal to be achieved of an energy management systemset of processes allowing energy objectives to be achieved (EnMSEnergy management system). The staff is aware and understands that, without their participation, the project cannot succeed.

Have confidence: success will come with the involvement and effort of all!

The vision (what we want to be), the mission (why we exist) and the business plan of the companya structure that satisfies a need are determined. The following step (4) includes the establishment of an outline of the energy policy and objectivesmeasurable goal to be achieved. If you do not have a copy of the ISO 50001 standard, now is the time to get it (see sub-clause 2.1 of the present course).

Planning is the last step (5) of the project preparation for obtaining ISO 50001 certification. A reasonable period is between 5 to 8 months (each companya structure that satisfies a need is unique and specific). The financial resources and staff are confirmed by top managementgroup or persons in charge of the organizational control at the highest level (see also ISO 9000, 3.1.1). An energy management team is appointed as project leader. Top management commitment is formalized in a documentany support allowing the treatment of information (see also ISO 9000, 3.8.5) communicated to all staff. A person is appointed project leader for obtaining ISO 50001 certification.

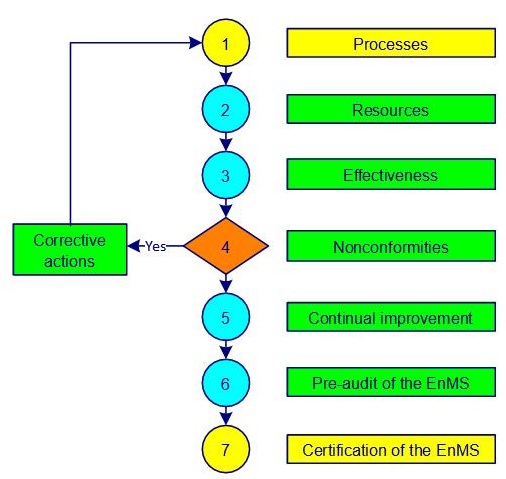

The establishment and implementation of an ISO 50001 energy management systemset of processes allowing energy objectives to be achieved are shown in figure 1-4.

Figure 1-4. QMS implementation

Step 1 aims to identify and determine the processes, interactions, owners, responsibilitiescapacity to make a decision alone and drafts of certain documents. The first versions of process sheets, job descriptions and work instructions are written with the participation of the maximum number of available persons.

The necessary resources to achieve the energy objectves are determined in step 2. Planning tasks, responsibilitiescapacity to make a decision alone and time frames are established. Training of internal auditorseveryone who is trained to carry out audits (see also ISO 19011, 3.8) is taken into account.

Step 3 allows you to set and implement methods for measuring the effectivenesscapacity to perform planned activities with minimum effort (see also ISO 9000, 3.7.11) and efficiencyfinancial relationship between achieved results and resources used (see also ISO 9000, 3.7.10) of each processactivities that transform inputs into outputs (see also ISO 9000, 3.4.1) (indicators). Internal auditssystematic and independent survey to determine whether activities and results comply with pre-established measures and are capable of achieving the objectives (see also ISO 19011, 3.1) help to evaluate the degree of implementation of the system.

Nonconformities of all kinds are listed in step 4. A first draft for dealing with wasteanything that adds cost but no value is established. Corrective actionsaction to eliminate the causes of nonconformity or any other undesirable event and to prevent their recurrence (see also ISO 9000, 3.12.2) are implemented and documented. A sorting out of correctve actions is introduced.

A first encounter with the tools and application areas of continual improvement is made in step 5. A table with the main costs of obtaining quality (COQcosts of obtaining quality) is filled by people with the information at hand. Riskslikelihood of occurrence of a threat or an opportunity (see also ISO Guide 73, 1.1) are determined, actions are planned and improvement opportunities are found. An approach to preventing nonconformitiesnon-fulfillment of a specified requirement (see also ISO 9000, 3.6.9) and eliminating causes is established. The internal and external communicationexchange of information is established and formalized.

To conduct the pre-audit of the EnMS (step 6), documentation is checked and approved by the appropriate people. A management reviewperiodic survey carried out by top management of the management system for its continual improvement allows evaluation of compliance with applicable requirementsexplicit or implicit need or expectation (see also ISO 9000, 3.6.4). The energy policy and objectivesmeasurable goal to be achieved are finalized. An energy manager from another companya structure that satisfies a need or a consultant can provide valuable feedback, suggestions and recommendations.

When the systemset of interacting processes (see also ISO 9000, 3.5.1) is accurately implemented and followed, the certification of the EnMS is a breeze, a formality (step 7).

An example of a certification project plan with 26 steps is shown in annex 01.

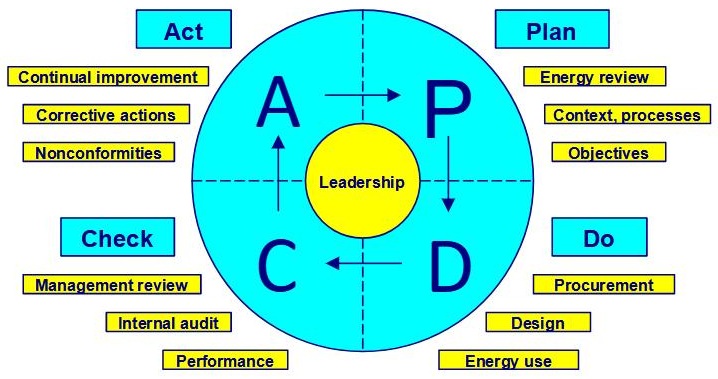

The Deming cycle (figure 1-5) is applied to control any processactivities that transform inputs into outputs (see also ISO 9000, 3.4.1). The PDCA cycles (Plan, Do, Check, Act) are a universal base for continual improvementprocess allowing the improvement of the global performance of the organization (see also ISO 9000, 3.3.2).

- Plan – define context, issues, and processes, demonstrate leadership, realize energy review, establish energy policy and objectives (clauses 4, 5 and 6)

- Do – procure equipment, develop, implement and control processes, optimize energy uses, demonstrate leadership and bring support (clauses 5, 7 and 8)

- Check – compare, verify, evaluate, inspect, analyze data, conduct audits and management reviews and demonstrate leadership (clauses 5 and 9)

- Act – adapt, demonstrate leadership, treat nonconformities, react with corrective actions and find new improvements (new PDCA cycle), (clauses 5 and 10)

For more information on the Deming cycle and is 14 points of management theory you can consult the classic book "Out of the crisis", W. Edwards Deming, MIT press, 1982.