4 Context of the organization .gif)

- 4.1 The organization and its context

- 4.2 Needs and expectations of stakeholders

- 4.3 Scope of the NSMS

- 4.4 NSMS and its processes

4.1 The organization and its context

External and internal issues that can influence the NSMS

Requirements 1 to 4 (see also the quiz)

The two most important things in a company do not appear in its balance sheet: its reputation and its people. Henry Ford

To successfully implement a nuclear safety management system, we must understand and evaluate everything that can influence the reason for being and business performancemeasurable and expected results of the management system (see also ISO 9000, 3.7.8). You should think carefully about a few key activities:

- develop a thorough diagnosis of the unique context in which your company exists, taking into account these issues:

- the external environment, such as:

- social

- regulatory

- economic

- technology

- the internal environment, such as:

- specific aspects of the corporate culture:

- vision

- rationale, purpose and mission

- core values

- staff

- products and services

- infrastructure

- nuclear safety risks and impacts on its activities

- specific aspects of the corporate culture:

- the external environment, such as:

- monitor and review regularly any information relating to external and internal issues

- analyze the factors that may influence the achievement of business objectives

- determine whether climate change is a relevant issue

The SWOT and PESTEL analyses can be useful for relevant analysis of business context (cf. annex 07).

A list of external and internal issues is carried out by a multidisciplinary team. Each issue is identified by its level of influence and control. Priority is given to issues with great influence and poor control.

.jpg) Minute of relaxation. Game: Context of the company

Minute of relaxation. Game: Context of the company

- diagnosis of the context includes the main external and internal issues

- the core values as part of the corporate culture are taken into account in the context of the company

- the results of the context analysis are widely diffused

- the SWOT analysis includes many relevant examples

- the SWOT analysis is a powerful tool for identifying the main threats and opportunities

- the issues of the context of the company, such as the competitive environment, are not taken into account

- in some cases, the corporate culture is not taken into account

- risk analysis does not take into account strategic issues

- no clear link between the SWOT analysis and the actions undertaken

4.2 Needs and expectations of stakeholders

Understand the requirements of stakeholders

Requirements 5 to 7

There is only one valid definition of a business purpose: to create a customer. Peter Drucker

To understand the needs and expectations of stakeholdersperson, group or organization that can affect or be affected by a company (see also ISO 26000, 2.20), we must begin by determining those who may be affected by the nuclear safety management system such as:

- employees

- customers

- external providers

- owners

- shareholders

- bankers

- distributors

- competitors

- citizens

- neighbors

- social and political organizations

A list of stakeholdersperson, group or organization that can affect or be affected by a company (see also ISO 26000, 2.20) is created by a multidisciplinary team. Every stakeholderperson, group or organization that can affect or be affected by a company (see also ISO 26000, 2.20) is determind by its level of influence and control. Priority is given to stakeholdersperson, group or organization that can affect or be affected by a company (see also ISO 26000, 2.20) with great influence and poor control.

Take into account that relevant stakeholdersperson, group or organization that can affect or be affected by a company (see also ISO 26000, 2.20) can have requirementsexplicit or implicit need or expectation (see also ISO 9000, 3.6.4) related to climate change.

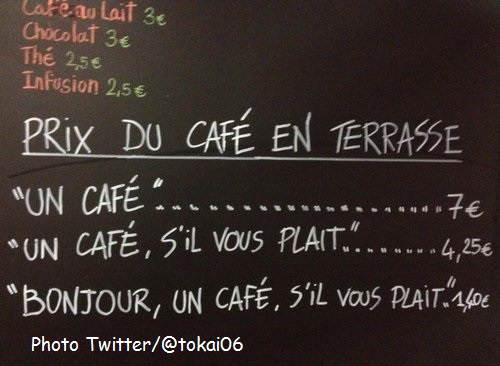

The customer is king but we still can fight against rudeness. This example is from the restaurant La petite Syrah in Nice and its coffee prices:

“A coffee”...................................7 €

“A coffee, please”...............4,25 €

“Hello, a coffee, please”....1,40 €

Anticipating the reasonable and relevant needs and expectations of stakeholdersperson, group or organization that can affect or be affected by a company (see also ISO 26000, 2.20) involves:

- meeting the requirements of the product or service offered

- preparing to address risks

- finding improvement opportunities

When a requirementexplicit or implicit need or expectation (see also ISO 9000, 3.6.4) is accepted, it becomes an internal requirementexplicit or implicit need or expectation (see also ISO 9000, 3.6.4) of the NSMSnuclear safety management system.

Quality means including the customer's point of view from design to final recycling

- the list of stakeholders parties is updated

- the needs and expectations of stakeholders are established through meetings on-site, surveys, roundtables and meetings (monthly or frequent)

- the application of statutory and regulatory requirements is a prevention approach and not a constraint

- statutory and regulatory requirements are not taken into account

- the delivery time is not validated by the customer

- the expectations of stakeholders are not determined

- the list of stakeholders does not contain their area of activity

4.3 Scope of the NSMS

Define the scope of the NSMS

Requirements 8 to 14

In many areas, the winner is the one who is best informed. André Muller

The scope (or in other words, the perimeter) of the nuclear safety management system is defined. When a requirementexplicit or implicit need or expectation (see also ISO 9000, 3.6.4) cannot be applied, a justification is included in the procedure that is maintained and is available to any stakeholderperson, group or organization that can affect or be affected by a company (see also ISO 26000, 2.20).

The specific context of the companya structure that satisfies a need is taken into account to determine the scope of the NSMSnuclear safety management system including:

- issues (cf. sub-clause 4.1)

- ITNS products and services

- nuclear safety culture

- environment:

- social

- financial

- technology

- economic

- requirements of stakeholders (cf. sub-clause 4.2)

- outsourced processes

- the scope is relevent and available upon request

- non applicable requirements are justified in writing

- some products are outside the scope of the NSMS without justification

- the paint shop is not included in the scope of the NSMS

- the requirements of a customer are not accepted and no justification is present

- the scope is obsolete (a new subsidiary is not included)

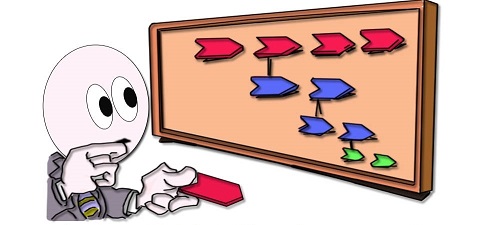

4.4 NSMS and its processes

NSMS requirements, processes and interactions

Requirements 15 to 27

If you cannot describe what you are doing as a process, you do not know what you're doing. Edwards Deming

The requirementsexplicit or implicit need or expectation (see also ISO 9000, 3.6.4) of the ISO 19443 standard include:

- management through quality and

- the control of business processes

To do this:

- the nuclear safety management system is:

- established

- documented (a simple and sufficient documentation system is set up)

- implemented and

- continually improved

- the quality policy, objectives, resources and the work environment are determined

- risks are determined and actions to reduce them are established (cf. sub-clause 6.1)

- the core necessary NSMS processes are controlled:

- corresponding resources are ensured

- the inputs and outputs are determined

- the necessary information is available

- owners are appointed (responsibilities and authorities defined)

- sequences and interactions are determined

- each process is measured and monitored (established criteria)

- objectives are set and performance indicators analyzed

- process performance is evaluated

- necessary changes are implemented to achieve the expected results

- actions to obtain the continual improvement of processes are established

- audits and reviews of the NSMS are performed regularly

- the necessary minimum ("as much as needed") of documentation on the processes is maintained and retained (

)

)

The nuclear safety manual is a requirementexplicit or implicit need or expectation (see also ISO 9000, 3.6.4) of ISO 19443 version 2018 (cf. sub-clause 4.4.3). It is a possible method to present the companya structure that satisfies a need, its NSMSnuclear safety management system and its proceduresdocument describing the to carry out a process (see also ISO 9000, 3.4.5 and documented information) and processesactivities that transform inputs into outputs (see also ISO 9000, 3.4.1) (cf. annex 08) and a description of how the requirements of the standard ISO 19443 are met.

The ISO guide “The integrated use of management system standards” of 2018, contains relevant recommendations on the integration of management systems.

.jpeg) Pitfalls to avoid:

Pitfalls to avoid:

- going overboard on quality:

.jpg)

- a useless operation is performed without adding value and without the customer asking for it - it is a waste, cf. quality tools D 12

- having all procedures written by the nuclear safety manager:

.jpg)

- quality is everybody's business, "the staff is conscious of the relevance and importance of each to the contribution to quality objectives", which is even more true for department heads and process owners

- forgetting to take into account the specificities related to the corporate culture:

.jpg)

- innovation, luxury, secrecy, authoritarian management (Apple)

- strong culture related to ecology, action and struggle, while cultivating secrecy (Greenpeace)

- fun and quirky corporate culture (Michel & Augustin)

- liberated company, the man is good, love your customer, shared dream (Favi)

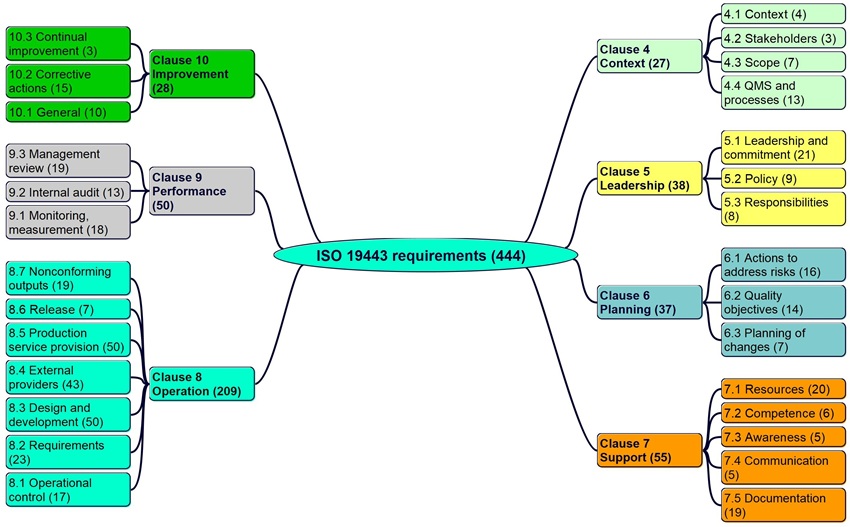

The requirements of the ISO 9001 standard are shown in figures 4-1:

Figure 4-1. The requirements of the ISO 19443:2018 standard

- the process map has enough arrows to show who is the customer (internal or external)

- for a process, it is better to use a lot of arrows (several customers) rather than to forget one

- reveal the added value of the process during the process review

- the analysis of processes performance is an example of continual improvement evidence of the effectiveness of the NSMS

- top management regularly monitors the objectives and action plans

- the purpose of each process is clearly defined

- process owners are members of the management team

- some process outputs are not set correctly (customers not considered)

- process efficiency criteria are not established

- the process owners are not formalized

- outsourced processes are not determined

- control of outsourced services is not described

- sequences and interactions of certain processes are not determined

- criteria and methods for ensuring effective processes are not determined

- monitoring the effectiveness of certain processes is not established

- the NSMS resources do not allow achievement of quality objectives

- the NSMS is not updated (new processes are not determined)

- the threats and weaknesses identified in the SWOT analysis remain without actions