2 Standards, definitions and books

2.1 Standards

Standards related to the QSE approach

ISOinternational organization for standardization standards are international and are voluntary.

Most often the standards used for an integrated management system are:

- ISO 9001 (2015): Quality management systems - Requirements

- ISO 45001 (2018): Occupational health and safety management systems – Requirements with guidance for use

- ISO 14001 (2015): Environmental management systems – Requirements with guidance for use

The guidelines for ISO 9001 are: ISO/TS 9002 (2016): Quality management systems - Guidelines for the application of ISO 9001:2015

For services the “ISO 20000-1 (2011) Information technology Service management Part 1: Service management system requirements” standard is very appropriate.

The ISO 9000 family of standards includes also:

- ISO 9000 (2015): Quality management systems – Fundamentals and vocabulary

- ISO 9004 (2018): Guidelines for achieving sustained success

The three QSEquality, safety, environment standards are generic because they apply to any company, without any constraints relating to size, activity or type. The scope of application of the QSEquality, safety, environment integrated management system is determined and documentation is kept up-to-date.

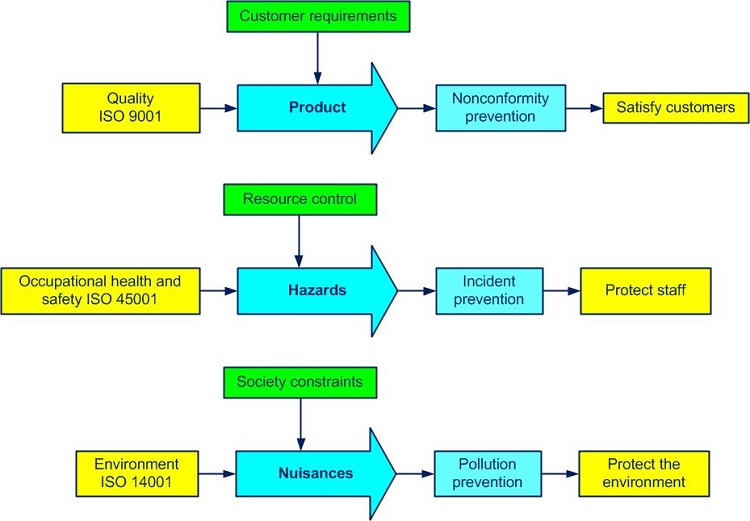

Similarities and differences in the purpose of the three standards are shown in figure 2-1:

Figure 2-1. Purpose of QSE standards

The structure of the ISO 9001, ISO 45001 and ISO 14001 standards is very similar and this is one of the reasons for the use of these standards in integrated QSEquality, safety, environment management systems.

Another demonstration of the close relationship between the three standards is the common standard ISO 19011 (2018 – third version): Guidelines for auditing management systems.

A British PAS (Publicly available specification) is dedicated to the integration of management systems:

- PAS 99: Specification of common management system requirements as a framework for integration, BSI, 2012

ISO 14004:2016 “Environmental management systems - General guidelines on implementation” contains a lot of explanations, practical advice and examples.

ISO 14005:2019 “Environmental management systems - Guidelines for a flexible approach to phased implementation” shows how to implement an environmental management system in 3 phases, 19 articles and 72 steps.

ISO 14031:2021 “Environmental management – Environmental performance evaluation - Guidelines” shows how to set up and use environmental performance evaluation (EPE) and life cycle analysis to find improvement points. Using indicators, we can evaluate our commitment to complying with legal and regulatory requirementsexplicit or implicit need or expectation (see also ISO 9000, 3.1.2), pollution prevention and continual improvementpermanent process allowing the improvement of the global performance of the organization (see also ISO 9000, 3.2.13 and ISO 14 001, 3.2).

The ISO 14044:2006 standard “Environmental management - Life cycle assessment - Requirements and guidelines” specifies the requirementsexplicit or implicit need or expectation (see also ISO 9000, 3.1.2) and provides guidelines for carrying out life cycle analyses.

The ISO 14063:2020 “Environmental management - Environmental communication - Guidelines and examples” standard provides guidelines on the general principles, policy, strategy and activities related to internal and external environmental communication.

The ISO 14050: 2020 “Environmental Management – Vocabulary” standard provides definitions of fundamental concepts, directly related to environmental management.

Two AFNOR documents are dedicated to the implementation of an IMSintegrated management system:

- the AC X50-200 agreement (2003): Integrated management system - Good practices and feedback and

- the documentation booklet FD X50-189 (2021): Management systems - Guidelines for their integration

And two other French documents related to the processes with explanations, recommendations and examples:

- AC X50-178 (agreement, 2002): Quality management – Process management – Good practices and feedback

- FD X50-176 (documentation booklet, 2017): Management tools – Process management

All these standards and many others can be ordered on the AFNOR (French Standardization Association) website in the standards catalog shop section.

The permanent Environment and Nuisance Code, Legislative Editions is reissued each year.

More than 28,000 standards (in English and other languages) are available free of charge on the Public.resource.Org website.

A site rich in very practical advice sheets is INERIS (National Institute of the Industrial Environment and Risks).

The standards in the ISO 10001 to ISO 10019 series are guidelines for integrated management systems and will help you find many answers (see ISO 9004: 2018, Bibliography).

Standards related to risks:

- ISO 31000: 2018, Risk management – Guidelines

- ISO 31010: 2009, Risk management – Risk assessment techniques

- ISO Guide 73: 2009, Risk management - Vocabulary

FMEAfailure mode and effects analysis documents:

- AIAG & VDA FMEA Handbook, AIAG, 2019

- CEI 60812: Failure modes and effects analysis (FMEA and FMECA), IEC, 2018

For automobiles:

- IATF 16949 - Quality management system requirements for automotive production and relevant service parts organizations, IATF, 2016

Other standards related to the QSEquality, safety, environment approach:

- The EFQM model, EFQM 2020

None of these standards are mandatory, but as Deming said:

It is not necessary to change. Survival is not mandatory

2.2 Definitions

QSE manager, definitions, terms, acronyms

The beginning of wisdom is the definition of terms. Socrates

The word responsible comes from the Latin respondere "to answer for one's actions".

Some authors replace the term QSEquality, safety, environment manager, with more or less success. Some synonyms, of which for the moment none manages to impose itself include:

- quality specialist

- QSE specialist

- animator

- facilitator

- responsible for non-quality

- administrator

- manager

- decision maker

- coordinator

- agent

- stirrer

- correspondent

- QSE director

- management representative (term used in the ISO 9001: 2008 standard)

- quality engineer

- quality delegate

- responsible for continual improvement

- adviser

- consultant

- in charge of mission

- assistant

Of course, neither the QSEquality, safety, environment manager nor the department are solely responsible for quality in a company. Deming says that 94% of the troubles belong to the systemset of interacting processes (see also ISO 9000, 3.2.1) for which top management is responsible.

In a company, everyone assumes their responsibilities, but the responsibility for the QSEquality, safety, environment approach begins with top management because, as the Romanian proverb says:

When you sweep the stairs, you start at the top. Romanian proverb

Some definitions and acronyms:

5 M: Mothe nature, Material,Method, Manpower, Machine (Fishbone or Ishikawa diagram)

5 S: from Japanese Seiri = sort, Seiton = set in order, Seiso = shine, Seiketsu = standardize and Shitsuke = sustain

5 W: five times Why?

Accident: unwanted event causing death or damage to health and the environment

Anomaly: variation compared to what is expected

AV: added value

CC: compliance cost

Conformity: fulfillment of a specified requirement

Control plan: document describing the specific measures to carry out the control of a product or process

Control: ensure compliance with the specified criteria

COQ: cost of obyaining quality

Corrective action: action to elimiate the causes of nonconfority or any other indesirable event and to prevent their recurrence

Criticality: level of a potential risk

Curative action: action to eliminate a detected nonconformity

Customer satisfaction: tthe top priority objective of every management system

Customer: the one who receives a product

Defect: nonconformity related to a specified use

Direction (top management): group or persons responsible for management at the highest level of the company

Document (documented information): any support allowing the processing of information

Dysfunction: deviation in the ability of a functional unit to perform a specified function

Effectiveness: capacity to perform planned activities with minimum effort

Efficiency: financial relationship between achieved results and resources used

Environment: space in which any organization functions

Environmental aspect: any element of a business that can react with the environment

Environmental impact: any change in the environment caused by an organization

Fail safe device: system allowing the prevention of errors by eliminating the human factor, also called Poka-Yoké

Failure: variation of an aptitude of a functional unit to satisfy a specified function

FMEA: Failure Mode and Effects Analysis

Gemba: from Japanese, real place, in the field

Hazard: situation that could lead to an incident

IMS: integrated management system

Incident: undesired event that could lead to health damages

Indicator: value of a parameter, associated with an objective, allowing the objective measure of its effectiveness

Integrated management system: set of processes to achieve QSE objectives

ISO: International Organization for Standardization

Kaizen: from Japanese, kai = change and zen = good (for the better, better), Kaizen = continual improvement

Management system: set of processes allowing objectives to be achieved

Manager: someone who gets results through other people

Muda: from Japanese, waste

Mura: from Japanese, irregularity

Muri: from Japanese, difficulty

Nonconformity (NC): non-fulfillment of a specified requirement

Non-quality: non-fulfillment of a specified requirement

Occupational health and safety: everything that can influence the wellbeing of the personnel in a company

OHS: occupational health and safety

Organization: a structure that satisfies a need

Performance: measurable and expected results of the management system

Poka-Yoké: pfrom Japanese Poka - unintentional error, Yoké - avoid. See Fail safe device

Preventive action: action to eliminate the potential causes of nonconformity or any other undesirable event and to prevent their appearance

Problem: gap that must be reduced to obtain a result

Process: activities that transform input into output

Product (or service): any result of a process or activity

QCDSE: Quality, Cost, Deadline, Safety, Environment

QSE objective: measurable goal to be achieved related to the QSE approach

QSE policy: statement by top management allowing the establishment of QSE objectives

QSE: quality, safety, environment

Quality management: activities allowing the control of an organization with regard to quality

Quality objective: quality related, measurable goal that must be achieved

Requirement: implicit or explicit need or expectation

Risk: likelihood of occurrence of a threat or an opportunity

Safety: absence of unacceptable risk

Scrap: treatment of an unrecoverable product

SMED: Single Minute Exchange of Die

SPC: Statistical Process Control

Stakeholder: person, group or company that can affect or be affected by an organization

System: set of interacting processes

Supplier (external provider): the one who procures a product

Top management: group or persons in charge of the organizational control at the highest level

TQC: Total Quality Control

Waste: anything that adds cost but no value

WWWWHHW: Who, What, Where, When, How, How much, Why

In the terminology used, do not confuse:

- accident and incident

- an accident is an unexpected serious event

- an incident is an event that can lead to an accident

- anomaly, defect, dysfunction, failure, nonconformity, reject and waste:

- an anomaly is a deviation from what is expected

- a defect is the non-fulfillment of a requirement related to an intended use

- a dysfunction is a degraded function that can lead to a failure

- a failure is when a function has become unfit

- a nonconformity is the non-fulfillment of a requirement in production

- a reject is a nonconforming product that will be destroyed

- waste is when there are added costs but no value

- audit program and plan

- an audit program is the annual planning of the audits

- an audit plan is the description of the audit activities

- audit, inspection, auditee and auditor

- an audit is the process of obtaining audit evidence

- an inspection is the conformity verification of a process or product

- an auditee is the one who is audited

- an auditor is the one who conducts the audit

- cause and symptom

- the cause is the circomstanceleading to a failure

- the symptom is the character linked to a state

- control and optimize

- to control is to meet the objectives

- to optimize is to search for the best possible results

- customer, external provider and subcontractor

- a customer receives a product

- an external provider provides a service or a product

- a subcontractor provides a product or service on which specific work is done

- effectiveness and efficiency

- effectiveness is the level of achievement of planned results

- efficiency is the ratio between results and resources

- follow-up and review

- follow-up is the verification of the obtained results of an action

- review is the analysis of the effectiveness in achieving objectives

- inform and communicate

- to inform is to give someone meaningful data

- to communicate is to pass on a message, to listen to the reaction and discuss

- objective and indicator

- an objective is a sought after commitment

- an indicator is the information on the difference between the pre-set objective and the achieved result

- organization and enterprise, society, company

- organization is the term used by the ISO 9001 standard as the entity between the supplier and the customer

- an enterprise, society and company are examples of organizations

- process, procedure, product, activity and task

- a process is how we satisfy the customer using people to achieve the objectives

- a procedure is the description of how we should conform to the rules

- a product is the result of a process

- an activity is a set of tasks

- a task is a sequence of simple operations

Remark 1: the use of ISO 9000, ISO 19011, ISO 45001 and ISO 14001 definitions is recommended. The most important thing is to determine a common and unequivocal vocabulary for everyone in the company.

Remark 2: the customer can also be the user, the beneficiary, the trigger, the ordering party or the consumer.

Remark 3: document or documented information is any information that we must maintain (procedure  ) or retain (record

) or retain (record  ).

).

Remark 4: each time you use the expression "opportunity for improvement" instead of nonconformity, malfunction or failure, you will gain a little more trust from your interlocutor (external or internal customer).

For other definitions, comments, explanations and interpretations that you don’t find in this module and in annex 06, you can consult:

.jpg)

- ISO Online Browsing platform (OBP)

- IEC Electropedia

.jpg) Minute of relaxation. Cf. game: Effectiveness

Minute of relaxation. Cf. game: Effectiveness

2.3 Books

Books related to quality, QSE manager, standards and tools

When I think of all the books still left for me to read, I am certain of further happiness. Jules Renard

.jpg) Books for further reading on quality:

Books for further reading on quality:

Armand V. Feigenbaum, Total Quality Control, McGraw-Hill, 1951

Armand V. Feigenbaum, Total Quality Control, McGraw-Hill, 1951  Kaoru Ishikawa, Guide to Quality Control, APO, 1971

Kaoru Ishikawa, Guide to Quality Control, APO, 1971 Philip B. Crosby, Quality is Free, Mentor, 1979

Philip B. Crosby, Quality is Free, Mentor, 1979  Kaoru Ishikawa, What Is Total Quality Control?, The Japanese Way, Prentice Hall, 1981

Kaoru Ishikawa, What Is Total Quality Control?, The Japanese Way, Prentice Hall, 1981  Charles Kepner, Benjamin Tregoe, The New Rational Manager, Princeton Research Press, 1981

Charles Kepner, Benjamin Tregoe, The New Rational Manager, Princeton Research Press, 1981 Edwards Deming, Out of the Crisis, MIT Press, 1982

Edwards Deming, Out of the Crisis, MIT Press, 1982 Kenneth Blanchard, Spencer Johnson, The One Minute Manager; The Quickest Way to Increase Your Own Prosperity, Berkley Books, 1982

Kenneth Blanchard, Spencer Johnson, The One Minute Manager; The Quickest Way to Increase Your Own Prosperity, Berkley Books, 1982  Eliyahou Goldratt, Jeff Cox, The Goal, A Process of Ongoing Improvement, North River Press, 1984

Eliyahou Goldratt, Jeff Cox, The Goal, A Process of Ongoing Improvement, North River Press, 1984 Masaaki Imai, KAIZEN, The key to Japan’s competitive success, McGraw-Hill, 1986

Masaaki Imai, KAIZEN, The key to Japan’s competitive success, McGraw-Hill, 1986 James H. Harrington, Poor-Quality Cost, Dekker, 1987

James H. Harrington, Poor-Quality Cost, Dekker, 1987 Taiichi Ohno, Toyota Production System: Beyond Large-Scale Production, Productivity Press, 1988

Taiichi Ohno, Toyota Production System: Beyond Large-Scale Production, Productivity Press, 1988 Stephen Covey, The Seven Habits of Effective People, Franklin Covey Co, 1989

Stephen Covey, The Seven Habits of Effective People, Franklin Covey Co, 1989 Peter Senge, The Fifth Discipline, The Art & Practice of The Learning Organization, Doubleday 1990

Peter Senge, The Fifth Discipline, The Art & Practice of The Learning Organization, Doubleday 1990 Edwards Deming, The New Economics, MIT Press 1993

Edwards Deming, The New Economics, MIT Press 1993.jpg) Masaaki Imai, GEMBA KAIZEN, A Commonsense Low-Cost Approach to management, McGraw-Hill, 1997

Masaaki Imai, GEMBA KAIZEN, A Commonsense Low-Cost Approach to management, McGraw-Hill, 1997 Peter Scholtes, The Leader’s Handbook, McGraw-Hill, 1997

Peter Scholtes, The Leader’s Handbook, McGraw-Hill, 1997 Jeffrey Liker, The Toyota Way, McGraw Hill, 2004

Jeffrey Liker, The Toyota Way, McGraw Hill, 2004 A. J. Edwards, ISO 14001 Environmental Certification Step by Step, Elsevier, 2004

A. J. Edwards, ISO 14001 Environmental Certification Step by Step, Elsevier, 2004 Ken Whitelaw, ISO 14001 Environmental Systems Handbook, Elsevier, 2004

Ken Whitelaw, ISO 14001 Environmental Systems Handbook, Elsevier, 2004 Nancy Tague, The Quality Toolbox, ASQ Quality Press, 2005

Nancy Tague, The Quality Toolbox, ASQ Quality Press, 2005 Larry Webber, Michael Wallace, Quality Control for Dummies, Wiley, 2007

Larry Webber, Michael Wallace, Quality Control for Dummies, Wiley, 2007 Denise Robitaille, The (Almost) Painless ISO 9001:2015 Transition, Paton Professional, 2015

Denise Robitaille, The (Almost) Painless ISO 9001:2015 Transition, Paton Professional, 2015 Jan Gillet, Implementing Iso 9001:2015: Thrill your customers and transform your cost base with the new gold standard for business management, Infinite Ideas, 2015

Jan Gillet, Implementing Iso 9001:2015: Thrill your customers and transform your cost base with the new gold standard for business management, Infinite Ideas, 2015 Charles Cianfrani, John West, ISO 9001:2015 Explained, ASQ Quality Press, 2015

Charles Cianfrani, John West, ISO 9001:2015 Explained, ASQ Quality Press, 2015 Craig Cochran, ISO 9001:2015 in Plain English, Paton Professional, 2015

Craig Cochran, ISO 9001:2015 in Plain English, Paton Professional, 2015 Denise Robitaille, ISO 9001:2015 Handbook for Small and Medium-Sized Businesses, Quality Press, 2016

Denise Robitaille, ISO 9001:2015 Handbook for Small and Medium-Sized Businesses, Quality Press, 2016 Jeremy Hazel, José Dominguez, Jim Collins, Memory Jogger ISO 9001:2015: What Is It? How Do I Do It? Tools and Techniques to Achieve It, Goal/QPC, 2016

Jeremy Hazel, José Dominguez, Jim Collins, Memory Jogger ISO 9001:2015: What Is It? How Do I Do It? Tools and Techniques to Achieve It, Goal/QPC, 2016 Alka Jarvis, Paul Palmes, ISO 9001: 2015: Understand, Implement, Succeed!, Prentice hall, 2016

Alka Jarvis, Paul Palmes, ISO 9001: 2015: Understand, Implement, Succeed!, Prentice hall, 2016 Ray Tricker, ISO 9001:2015 for Small Businesses, Routledge, 2016

Ray Tricker, ISO 9001:2015 for Small Businesses, Routledge, 2016 Christopher Paris, Surviving ISO 9001: 2015, Oxebridge Quality Press, 2016

Christopher Paris, Surviving ISO 9001: 2015, Oxebridge Quality Press, 2016  Team, Quality Manager A Complete Guide - 2021 Edition, The Art of Service - Quality Manager Publishing, 2020

Team, Quality Manager A Complete Guide - 2021 Edition, The Art of Service - Quality Manager Publishing, 2020 Tawanda Muzamwese, Step by step guide to implementing safety, health, environment and quality management systems (sustainability), National archives of Zimbabwe, 2020

Tawanda Muzamwese, Step by step guide to implementing safety, health, environment and quality management systems (sustainability), National archives of Zimbabwe, 2020 Sachin Grover, Ramesh Grover, Implementing integrated management system for quality, environment, occupational health & safety and energy, Notion Press, 2021

Sachin Grover, Ramesh Grover, Implementing integrated management system for quality, environment, occupational health & safety and energy, Notion Press, 2021 Massimiliano Mazzei, Being a Quality Manager: Quality Manager's Notebook, Independently published, 2023

Massimiliano Mazzei, Being a Quality Manager: Quality Manager's Notebook, Independently published, 2023 Stephen Asbury, Health and Safety, Environment and Quality Audits, CRC Press, 2023

Stephen Asbury, Health and Safety, Environment and Quality Audits, CRC Press, 2023

.jpg) Minute of relaxation. Paganini's violin concert performed with facial expressions.

Minute of relaxation. Paganini's violin concert performed with facial expressions.