4 Competence .gif)

4.1 General

Factors, competence, expertise

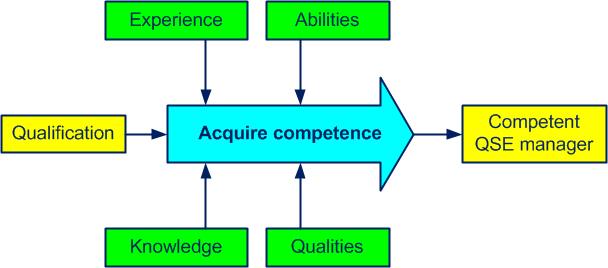

The competence of the QSEquality, safety, environment manager is the result of various factors. Figure 4-1 shows the Acquire competence processactivities which transform inputs into outputs (see also ISO 9000, 3.4.1) of the QSEquality, safety, environment manager.

Figure 4-1. The acquire competence process of the QSE manager

Competence: personal skills, knowledge and experiences

The competence of the QSEquality, safety, environment manager is constantly improved thanks to:

- individual learning

- continual training and

- professional experience in the field

Imagination is more important than knowledge. Albert Einstein

Areas of expertise in which the QSEquality, safety, environment manager excels:

- think system (understand the difference between a system and elements such as structure, policy, process)

- always consider all stakeholders

- pass on knowledge

- communicate clearly on:

- the vision

- the strategy

- policy and

- the objectives

- distinguish:

- a common cause (inherent to the system as a defect, error, waste) of a special cause of variation (as a statistical measurement outside the limits, malfunction of a machine). This allows one to:

- see the trends where there really are

- attribute a priori the problems to the system and not to the individuals

- identify opportunities for system improvement

- the opinion from the fact

- the modification from the improvement (the improvement is a modification at a higher level)

- motivating factors from demotivating factors

- customer’s implicit expectations from explicit ones

- a common cause (inherent to the system as a defect, error, waste) of a special cause of variation (as a statistical measurement outside the limits, malfunction of a machine). This allows one to:

A pharmaceutical laboratory generates 500 kg/month of hazardous waste (solvents, chemicals), with risks of:

• regulatory non-compliance (ADR, REACH regulations)

• accidental pollution (leaks, improper storage)

• high treatment costs (€15,000/year)

Proposed corrective actions:

• source sorting: installation of dedicated containers for each type of waste

• team training in hazardous waste management

• partnership with a certified waste treatment service provider

• implementation of a dashboard to track waste quantities

• annual audit by an accredited organization

Results achieved:

• 40% reduction in hazardous waste in 2 years

• full compliance with ADR and REACH regulations

• 25% savings on treatment costs

4.2 Qualification

Education, diplomas

The QSEquality, safety, environment manager has completed higher education (three to six years Bachelor's degree).

Now we can rejoice over the embarrassment of choices for diplomas (bachelor, master) that integrate the QSEquality, safety, environment approach delivered by a large number of universities or engineering and business schools.

A dairy processing plant has an 8% reject rate (yogurts, cheeses), due to:

• raw material variability

• poor process control (temperatures, fermentation times)

• insufficient quality controls

Proposed corrective actions:

• implementation of real-time temperature sensors on the lines

• operator training in good manufacturing practices

• strengthened quality controls (random sampling)

• partnership with suppliers to stabilize raw material quality

• creation of a QSE working group (operators + management)

Results achieved:

• reject rate reduced to 2% in 12 months

• improved customer satisfaction (zero quality-related complaints)

• saving of €500,000/year in production costs

4.3 Experience

Environment, experience in the field

The QSEquality, safety, environment manager knows how to adapt to any environment. The QSEquality, safety, environment manager aspires to entrance their close entourage. For this the QSEquality, safety, environment manager will learn and assimilate very quickly, thanks to a successful experience in the field, the data specific to the company:

- general organization

- strategy (major projects)

- the creation and history of the company

- corporate culture (values, habits, practices, language)

- the processes and their interactions (the trades)

- products

- the economic sector (competitors)

- customers, suppliers, partners and other stakeholders

- production flows

- the technologies and materials used

- the results achieved and the short and long term objectives

- the documentary system

- computer tools

Following a serious problem, the director himself goes to the customer.

On the spot, he explains that everything will be done to resolve the situation. He's sorry for what happened. That it won't happen again.

When asked what the root cause of the problem is and what action plan is being considered his response is, "Oh, you know, I don't go into that kind of detail, but I promise you this will all be resolved very soon."

The market was lost.

Going, seeing and understanding in the field and always checking the facts yourself is not a wish, it is a prerequisite for any sustainable business.

4.4 Knowledge

Knowledge, areas

There is no substitute for knowledge. Edwards Deming

The QSEquality, safety, environment manager has solid knowledge in the following areas:

- management system (QSE, integrated and others)

- standards concerning management systems

- certification principles

- QSE tools

- applicable legal and regulatory requirements

- computer science

- foreign languages. This is always a plus

- QSE terminology

A transport logistics company emits 2,500 tons of CO₂/year and wishes to:

• reduce its carbon footprint by 30% in 3 years

• optimize its energy costs

• anticipate environmental regulations (carbon tax)

Proposed corrective actions:

• switch to a fleet of electric/hybrid vehicles

• optimize routes using smart routing software

• train drivers in eco-driving

• install solar panels in warehouses

• raise customer awareness of grouped deliveries

Results achieved:

• 35% reduction in CO₂ emissions in 3 years

• saving of €120,000/year in energy costs

• strengthen sustainable development image ("Company Committed to the Climate" label)

.jpg) Minute of relaxation. Cf. game: Competence

Minute of relaxation. Cf. game: Competence

4.5 Abilities

Ideal QSE manager, natural leader, confortable with

The leader is the one who climbs the tallest tree, surveys the entire situation, and yells, ''Wrong jungle!'' Stephen Covey

The “ideal” QSEquality, safety, environment manager is someone who:

- strongly believes in the necessity of its mission (QSE approach is a profit center)

- think globally (system approach)

- always remembers to be the customer's ambassador

- is pragmatic

- is a natural leader:

- is aware of the role's responsibilities and commitment

- enforces authority

- shows themself to be at the service of the group

- is results oriented

- goes straight to the point

- knows how to be flexible

- defines coherent objectives and contributes to their achievement

- knows how to gain everyone's trust

- shares the hard times and the joys with the team

- love the job

- arouses creative tension

- is capable of critical analysis on the work carried out and not on the people

- knows how to initiate a dialogue on ideas:

- news

- extravagant

- sometimes provocative

- launches stimulating challenges

- is always open to learning more

- believes a priori that people:

- are good

- are trustworthy

- want to do their best

- always wants to do better than yesterday (is never fully satisfied with the current situation)

- is sensitive to waste

- knows how to quickly find realistic solutions

- strives to:

- convince rather than impose

- influence rather than lead

- prefers to raise awareness by thinking (thinking about the why) than prompting the right answer (explaining the how)

- shows how to break down barriers between departments

- devotes sufficient time to anticipating the future

- dares to surprise

- shares the vision. Convincingly explains:

- the link between the purpose of the individual work, the team and the company

- how individual performance affects the overall performance of the company

- that the journey to excellence is our salvation

- is comfortable with:

- daily contact in the field

- team motivation

- the right behavior at the right time

- the PDCA cycle

- QSE tools

- flow charts

- the spirit of the standards

- meticulous preparation, thoughtful planning

- collecting information

- identifying implicit customer needs

- statistical analysis of data and graphical presentation of trends

- the measurements, the analysis of the results and the actions to be taken

- inspection techniques

- running meetings

- top management, staff, customer

- the will to succeed

- discipline

- chasing the boredom of repetitive work

- negotiation (looking for a win/win result)

- observation (understand well before acting)

- adaptation to innovation

- has a good memory of:

- terms and definitions

- principles and methods

- requirements and constraints

- facts and ideas

A call center with 200 employees is facing:

• 40% turnover (compared to 20% in the sector)

• stress-related sick leave (15% of the workforce)

• a decline in service quality (customer satisfaction at 70%)

Proposed corrective actions:

• implementation of a job rotation system to reduce monotony

• training of managers in the prevention of psychosocial risks (PSR)

• creation of a relaxation area (break room, relaxing activities)

• reduction of individual objectives in favor of collective objectives

• establishment of a toll-free number for psychological support

Results achieved:

• turnover reduced to 15% in 18 months

• customer satisfaction increased to 90%

• 50% reduction in stress-related sick leave

4.6 Qualities

Qualities of the ideal QSE manager, pitfalls to avoid

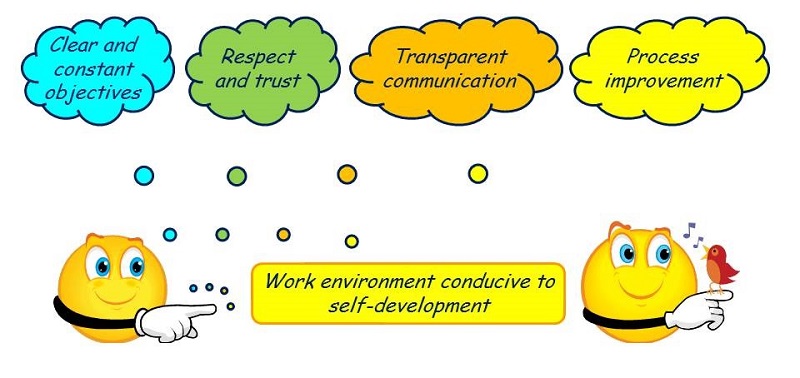

Figure 4-2 shows some of the key factors that are essential for staff success.

Figure 4-2. Desirable work environment

A good leader gets extraordinary things from ordinary men. Peter Drucker

The “ideal” QSEquality, safety, environment manager has qualities such as:

- has:

- common sense

- the sense of reality

- innovative ideas

- charm

- want to:

- learn more and more

- pass on knowledge

- knows how to:

- organize

- coordinate work

- make time an ally

- take a step back and think calmly

- delegate work, a responsibility

- distribute the work (one action, one goal, one responsible)

- lead by example, do and be what you say (speak especially with your actions)

- show how to eliminate waste

- generate support and enthusiasm to move towards a common goal (proposing dreamy goals)

- formalize and document

- lead a team, work in a team

- avoid conflicts

- lean on others

- appreciate, encourage and reward the work of others

- take staff comments into account

- assess the value of proposals

- measure performance

- separate:

- the essential facts from the insignificant

- the causes from the effects

- establish a harmonious work environment

- eliminate fear, stress (return to realistic goals)

- chase away anxiety (improve the know-how)

- smile from time to time

- take the right decision at the right time and apply it without delay

- launch initiatives

- listen carefully to all stakeholders with:

- patience

- willingness to understand (listening with empathy)

- respect

- speak clearly

- communicate:

- orally and via different media

- internally and externally

- on customer satisfaction and dissatisfaction

- ask the right questions (with the help of Rudyard Kipling and his six faithful friends: “Their names are What and Why and When and Where and Who and How”)

- convince interlocutors of the merits of decisions

- argue their point of view (entrance in order to convince)

- raise awareness, mobilize, train staff in QSE approaches

- motivate, inspire and stimulate staff

- say congratulations and thank you

- question oneself (“What am I for?”)

- acknowledge mistakes and build on lessons learned

- help and support initiatives

- monitor any action taken

- coordinate any improvement project

- find the balance between action that is:

- simple and perfection

- agile and rigor

- immediate and long term

- small steps and big change

- regular and the unusual

- advise by remaining humble

- explain the purpose, policy, objectives, procedures, tools

- reassure top management, staff and the customer

- simplify problems and solutions

- train its team members and staff

- apply methods, principles and ideas

- involve suppliers

- drive change

- say no, resist pressure, use your right of veto

- detect the warning signs (weak signals) of an unprecedented situation

- anticipate problems

- deal calmly with the unexpected

- respond to emergencies with self-control

- manage risks

- is:

- rigorous (PDCA cycle)

- modest

- ambitious, but realistic

- tolerant, accepting and respecting his interlocutor

- curious

- a source of:

- proposal

- inspirational

- progress

- change

- action-oriented, dynamic

- responsive, agile

- objective, impartial

- an accomplice of the teams in the field

- accessible and available

- persevering (always go to the end without letting go)

- patient, but not too much

- motivated, passionate, enthusiastic

- a unifier

- reliable

- benevolent, but not naïve

- balanced

- a pedagogue in the face of resistance to change

- favors:

- security

- prevention

- good mood

- the logic

- simplicity

- diplomacy

- impartiality

- honesty

- empathy

- careful observation

- precise writing

- standardized work

- in-depth analysis

- customer satisfaction, not top management

- feedback based on facts, not opinions

- tenacity

- autonomy

- discretion

- serenity

- the improvement of the system and not the pecuniary evaluation of performance

A production manager believed that on-time delivery, no matter what, was a top priority.

He had to deliver parts for a major customer. Having not received solder paste within the planned timeframe, he ordered the use of expired solder paste. Delivery was made on time. The customer, after a few tests, returned the entire batch as non-compliant. The financial penalty was enormous. This was one of the causes of the company's liquidation a few weeks later.

The production manager hid his override decision from the customer and his quality manager. The expired solder paste was to be destroyed as soon as the expiration date had passed. Two fatal malfunctions.

A presence of mind test can be found in annex 08.

Pitfalls to avoid:

- sharing advice or opinions

- neglecting the work place at the expense of your office

- being afraid to step out of your comfort zone

- saying “I will do…”

- using terms with ambiguous or incomprehensible meanings for staff

- exaggerating certain facts

- behaving like a policeman

- being perceived as a constraint

- addressing unjustified criticism

- making a promise and don't keep it

- showing that you feel more intelligent (or competent) than your interlocutor

- not accepting what the customer observed

- keeping people waiting for you

- being difficult to access

- raising voice

- showing irony

- forgetting to say hello

- ending an interview abruptly

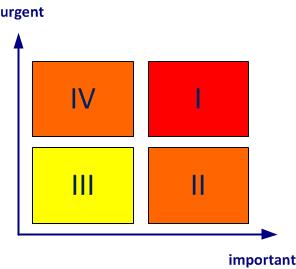

Choosing priorities requires a great deal of effort and sensitivity to the individual's perception of their mission. Figure 4-3 shows the activities classified into four sections.

Figure 4-3. Priority of activities

Urgent and important activities (Section I) include, for example:

- crisis situation

- risk management

- customer returns

- treatment of nonconformities

Important and non-urgent activities (Section II) include, for example:

- staff involvement

- control of risk prevention

- hunting for waste

- application of QSE procedures and tools

- personal education

- improvement of the IMS

Non-urgent and non-important activities (section III) include, for example:

- endless discussions (like the chicken and egg paradox)

- improvement of the form of procedures and other documents

- long and unnecessary meetings

- some phone calls

- monthly and quarterly reports

- some emails and letters (quotes, future projects)

Urgent and non-important activities (section IV) include, for example:

- some phone calls

- too frequent meetings

- reports that people from other departments should make

- certain emails and letters

The object of the game is to manage your time by giving high priority to the activities of section II, especially to the detriment of the activities of sections III and IV.

A cement factory emits 50,000 tons of CO₂ per year and must comply with new environmental regulations (carbon tax, Paris Agreement). The goal is to reduce emissions by 20% in two years. Issues identified:

• high consumption of fossil fuels (coal for furnaces)

• lack of waste recycling (tires, sludge)

• lack of real-time emissions monitoring

Proposed corrective actions:

• partial replacement of coal with alternative fuels (biomass, recycled waste)

• optimization of furnaces (better insulation, heat recovery)

• implementation of an emissions monitoring system (sensors + software)

• employee training in eco-friendly practices (shutdown of unnecessary equipment)

• partnership with a recycling company to recover waste

Results achieved:

• 25% reduction in emissions (target exceeded)

• €1.2 million/year in energy costs saved

• ISO 14001 certification obtained

Minute of relaxation. Cf. joke “Is hell exothermic or endothermic?”

Minute of relaxation. Cf. joke “Is hell exothermic or endothermic?”

The rest of the T 62 QSE manager training is accessible on this page.