4 Planning and preparation .gif)

4.1 Purpose

When to plan and initiate a FMECA

By failing to prepare, you are preparing to fail. Benjamin Franklin

The purpose of the first step is to determine which FMEAfailure mode and effects analysis will be carried out for the project (productany outcome of a process or activity (see also ISO 9000, 3.4.2), processactivities which transform inputs into outputs (see also ISO 9000, 3.4.1) or other). Planning and preparation allows you to:

- identify the project (fill in the headings)

- respond to the 5Ts: InTent, Timing, Team, Tasks, Tools

- define the scope (what goes and does not go into the analysis)

- prioritize systems, functions or processes

- prepare the structure analysis

4.2 Planning

Inputs of step 1, FMEA header, case studies, questions before starting

The inputs in step 1 can be:

- customer specifications

- legal requirements

- documents relating to the scope

- similar FMEAs

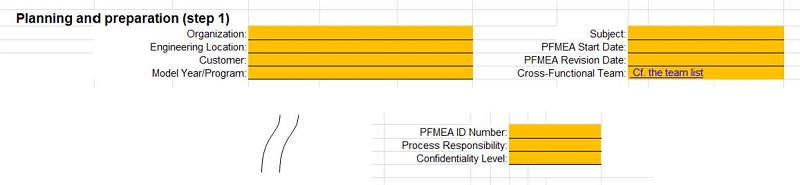

One of the first tasks to be undertaken is to complete the header of the design FMEAfailure mode and effects analysis (cf. DFMEA sheet, annex 02) and processactivities which transform inputs into outputs (see also ISO 9000, 3.4.1) FMEAfailure mode and effects analysis (see PFMEA sheet, annex 03), shown in figures 4 -1 and 4-2:

Figure 4-1. Design FMEA header

Figure 4-2. Process FMEA header

The only difference between design and process FMEA is in the appointment of the Design responsibility and Process responsibility.

A FMEAfailure mode and effects analysis is performed in the following cases:

- new product, process, technology

- new application of a process, product, technology

- improvement of a process, product, technology

- production in a modified environment

- new regulatory requirements

- ergonomic issues

- process failure that could lead to hazards

- internal problem or customer return

Before starting a FMEAfailure mode and effects analysis, the following questions must be answered:

- why do this FMEA?

- is it requested by the customer?

- what are the customer's wishes, needs, expectations?

- what is the added value for the customer?

- who will be on the team?

- will the analysis focus on a system, a subsystem or a component?

- what is the complexity of the design?

- when to start FMEA?

- what work will be done?

- what are the constraints?

- are there any new requirements?

- how will the analysis be done?

- what are we going to evaluate?

It's never too early to start the FMEA, it is sometimes too late to still present a real interest. Gérard Landy

FMEAfailure mode and effects analysiss on productsany outcome of a process or activity (see also ISO 9000, 3.4.2), processes and similar means already produced will be used as a knowledge base. The Quality Function Deployment - QFD tool can provide valuable help, cf. annex 09.

Planning for FMEAfailure mode and effects analysis should be done early in product start-up. This is so as to allow the failure modes to be detected as early as possible in the industrialization schedule of a productany outcome of a process or activity (see also ISO 9000, 3.4.2). And therefore to provide a solution as much as possible before sending the quotation to the customeranyone who receives a product (see also ISO 9000, 3.3.5) (so that the costs of Poka-Yoké and other error-proofing systems specific to the productany outcome of a process or activity (see also ISO 9000, 3.4.2) are included in the quotation and paid by the customeranyone who receives a product (see also ISO 9000, 3.3.5)) .

4.3 Preparation

FMEA team members, first meeting, FMEA documents, outputs from step 1

The person designated by top management as FMEAfailure mode and effects analysis leader is responsible for setting up the FMEAfailure mode and effects analysis multidisciplinary team which may include a:

- facilitator responsible for:

- design

- development

- QSE (quality, safety, environment)

- manufacturing

- system

- logistics

- safety

- test

- project

- purchases

- commercial

- components

- maintenance

- technical expert

- technician

- operator

- consultant

- customer representative

The first team meeting (optimal number between 5 to 7 people) makes it possible to define:

- the subject

- the scope and limits (the field of application)

- the terms used

- the rules of the game to be respected (tables of ratings)

- the objectives to be achieved

- assured resources

- the deadline to be respected (the deadline for the analysis)

- the responsibilities to be assumed

If the leader is different from the facilitator, the latter will be responsible for the application in the field of the FMEAfailure mode and effects analysis, for meeting the deadline and cost. External people can be invited for advice or expertise.

The scope of FMEAfailure mode and effects analysis is defined, customeranyone who receives a product (see also ISO 9000, 3.3.5) requirementsexplicit or implicit need or expectation (see also ISO 9000, 3.1.2) are clarified, and similar FMEAfailure mode and effects analysiss are reviewed.

All documents providing objective data on the productsany outcome of a process or activity (see also ISO 9000, 3.4.2) (processes) studied are an essential basis for the conduct of FMEAfailure mode and effects analysis, and it is therefore imperative that they are collected by the facilitator before the first meeting or brought by the participants during the meeting.

Among these documents, we can note in a non-exhaustive way:

- the flowchart describing with precision all the steps of the product (process) as well as the components and tools associated with each stage

- the customer's plans, specifications, special characteristics, technical requirements, rating tables and nomenclatures to identify, among other things, the critical, regulatory or safety parameters of the product (process)

- the functional specifications

- the results of the risk assessment

- regulatory standards required for the product (process)

- legal requirements

- the specifications of the equipment and machines

- the generic or similar maintenance file

- monitoring and measurement records to quantify the quality results obtained with the product (process) or with a similar product (process)

- the capability studies carried out on the process

- the result of comparative studies carried out on a similar product (process) of the company

- the requirements for error-proofing devices

- the history of results from other sites on a similar product (process)

- the history of customers / suppliers / competitors on a similar product (process)

- generic FMEA relating to the product (process)

- similar FMEA

- the FMEA support to be completed and registered

The outputs of step 1 can be:

- the defined scope

- the objectives set

- the determined deadline

- the list of team members

- validated customer requirements

Minute of relaxation. Cf. joke "Gold contract"

Minute of relaxation. Cf. joke "Gold contract"

The rest of the T 45v19 FMEA approach version 2019 training is accessible on this page.