2 Standards, definitions and books

There can be no improvements where there are no standards. Masaaki imai

2.1 Standards

FMEA standards and references

.jpg) References on which this module is based:

References on which this module is based:

- Potential Failure Mode and Effects Analysis, AIAG, 2008

- J 1739: Potential Failure Mode and Effects Analysis in Design (Design FMEA), Potential Failure Mode and Effects Analysis in Manufacturing and Assembly Processes (Process FMEA), SAE, 2009

- NF X50-100: Management by value - Functional analysis, fundamental characteristics - Functional analysis: functional analysis of the need (or external) and technical / product (or internal) functional analysis - Requirements on deliverables and implementation procedures, AFNOR, 2011

- BS EN 16271: Management by value - Value management - Functional expression of the need and functional performance specification - Requirements for expressing and validating the need to be satisfied within the process of purchasing or obtaining a product, BSI, 2012

- NF EN 1325: Value Management, Vocabulary, Terms and definitions, AFNOR, 2014

- ISO 9001: Quality management systems. Requirements, ISO, 2015

- IATF 16949: 2016 - Quality management system requirements for automotive production and relevant service parts organisations, IATF, 2016

- BS EN IEC 60812, Analysis of failure modes and their effects (FMEA and FMECA), BSI, 2018

- AIAG & VDA FMEA Handbook, AIAG, 2019

The IATF 16949 standard, version 2016, includes specific requirementsexplicit or implicit need or expectation (see also ISO 9000, 3.1.2) for the automotive industry.

Some of these requirementsexplicit or implicit need or expectation (see also ISO 9000, 3.1.2) (cf. annex B of the standard) are:

- strategic plan

- special characteristics

- advanced product quality planning, APQP

- failure modes, their effects and their criticality analysis, FMECA

- control plan (cf. annex 04)

.gif)

- laboratory control

- production part approval process, PPAP

Many other standards and books can be ordered on the ISO site.

Over 28,000 standards (in English and other languages) are available free of charge from the Public.Resource.Org site.

The Oxebridge Q001 is a user-friendly, open source remix of ISO 9001:2015.

2.2 Definitions

Terms and definitions related to FMEA

The beginning of wisdom is the definition of terms. Socrates

Specific quality terms:

APQP: Advanced Product Quality Planning

Company (organization): structure that satisfies a need

Control plan: document describing the specific provisions for controlling the product or process

Corrective action: action to eliminate the causes of nonconformity or any other undesirable event and to prevent their recurrence

Criticality: level of a potential risk

Customer: the one who receives a product

Failure: tdeviation in the ability of a functional unit to satisfy a specific function

Fail safe device: system allowing error prevention by eliminating the human factor (Poka-Yoké)

FMECA: Failure Modes, Effects and Criticality Analysis

FMEA: Failure Mode and Effects Analysis

PPAP: Product Part Approval Process

Preventive action: action to eliminate the potential causes of nonconformity or any other undesirable event and prevent their occurrence

Problem: gap that must be reduced to obtain a result

Process: activities that transform inputs into outputs

Product (or service): every result of a process or activity

Quality: aptitude to fulfill requirements

Quality management system: everything necessary for the quality management of a company

Requirement: explicit or implicit need or expectation

Risk: likelihood of occurrence of a threat or an opportunity

Special characteristic: lcharacteristic of a product or process that could relate to product safety or regulatory compliance or could decrease customer satisfaction

Supplier: the one who procures a product

In the terminology of quality management systems, do not confuse:

- anomaly, defect, dysfunction, failure, nonconformity, reject and waste:

- an anomaly is a deviation from what is expected

- a defect is the non-fulfillment of a requirement related to an intended use

- a dysfunction is a degraded function that can lead to a failure

- a failure is when a function has become unfit

- nonconformity is the non-fulfillment of a requirement in production

- a reject is a nonconforming product that will be destroyed

- waste is when there are added costs but no value

- control and optimize

- to control is to meet the objectives

- to optimize is to search for the best possible results

- customer, external provider and subcontractor

- a customer receives a product

- an external provider provides a service or a product

- a subcontractor provides a product or service on which specific work is done

- effectiveness and efficiency

- effectiveness is the level of achievement of planned results

- efficiency is the ratio between results and resources

- follow-up and review

- follow-up is the verification of the obtained results of an action

- a review is the analysis of the effectiveness in achieving objectives

- inform and communicate

- to inform is to give someone meaningful data

- to communicate is to pass on a message, to listen to the reaction and discuss

- objective and indicator

- an objective is a sought after commitment

- an indicator is the information on the difference between the pre-set objective and the achieved result

- organization and enterprise, society, company

- organization is the term used by the ISO 9001 standard as the entity between the supplier and the customer

- enterprises, societies and companies are examples of organizations

- process, procedure, product, activity and task

- a process is how we satisfy the customer using people to achieve the objectives

- a procedure is the description of how we should conform to the rules

- a product is the result of a process

- an activity is a set of tasks

- a task is a sequence of simple operations

Remark 1: the use of ISO 9000 and IATF 16949 definitions is recommended. The most important thing is to determinate a common and unequivocal vocabulary for everyone in the company.

Remark 2: the customer can also be the user, the beneficiary, the trigger, the ordering party, the consumer.

Remark 3: documented information is any information that we must maintain (procedure .gif) ) or retain (record

) or retain (record .gif) )

)

For other definitions, comments, explanations and interpretations that you don’t find in this module and annex 06, you can consult: .jpg)

.gif)

- ISO Online Browsing platform (OBP)

- IEC Electropedia

2.3 Books

Books related to FMEA

When I think of all the books still left for me to read, I am certain of further happiness. Jules Renard

.jpg) Books for further reading on FMEAfailure mode and effects analysis:

Books for further reading on FMEAfailure mode and effects analysis:

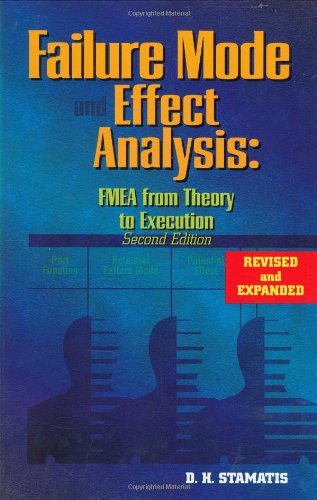

D H Stamatis, Failure Mode and Effect Analysis, ASQ, 2003

D H Stamatis, Failure Mode and Effect Analysis, ASQ, 2003 Raymond Mikulak et al, The Basics of FMEA, CRC Press, 2008

Raymond Mikulak et al, The Basics of FMEA, CRC Press, 2008  Gérard Landy, AMDEC - Guide pratique, AFNOR, 2011 (FMEA - Practical guide)

Gérard Landy, AMDEC - Guide pratique, AFNOR, 2011 (FMEA - Practical guide) Fulbodh Chaudhary, Concept and case study FMEA and control plan, Independently published, 2016

Fulbodh Chaudhary, Concept and case study FMEA and control plan, Independently published, 2016 D.H. Stamatis, Risk Management Using Failure Model and Effect Analysis (FMEA), ASQ Quality Press, 2019

D.H. Stamatis, Risk Management Using Failure Model and Effect Analysis (FMEA), ASQ Quality Press, 2019 Gerardus Blokdyk, FMEA A Complete Guide - 2020 Edition, 5starcooks, 2019

Gerardus Blokdyk, FMEA A Complete Guide - 2020 Edition, 5starcooks, 2019 Mohammed Hamed Ahmed Soliman, Practical Guide to FMEA : A Proactive Approach to Failure Analysis, Independently published, 2020

Mohammed Hamed Ahmed Soliman, Practical Guide to FMEA : A Proactive Approach to Failure Analysis, Independently published, 2020

.jpg) Minute of relaxation. Game: Procedure

Minute of relaxation. Game: Procedure