IATF 16949 version 2016 requirements, automotive quality management system

20/11/2017

Quiz requirements IATF 16949 version 2016 You want to familiarize yourself with the structure of the standard, identify and understand the requirements of IATF 16949 version 2016, then it's up to you to play!

The "IATF 16949 version 2016 Requirements" quiz will help you understand the main requirements of the standard.

The questions (requirements) included in this quiz are 108 of the 511 in the standard, but don't worry. These 108 requirements are among the most important. So do not hesitate to learn in a fun way!

Do not think you can finish this quiz in less than an hour, or even two hours, unless of course you are a little genius!

News about ISO 9001 version 2015

The ISO 9001 version 2015 requirements

Some news about the IATF 16949 version 2016

The course T 15v15 ISO 9001 version 2015 readiness

The course T 35v15 ISO 9001 version 2015 internal audit

The package of courses T 65v15 training package ISO 9001 version 2015 readiness and internal audit

The course T 16v16 IATF 16949 version 2016 readiness and its free demo

The course T 36v16 IATF 16949 version 2016 internal audit and its free demo

The package of courses T 66v16 training package IATF version 2016 readiness and internal audit

Based on ISO 9001 version 2015 the 309 requirements (verb shall) of clauses 4 to 10 are as follows:

|

ISO 9001 version 2015 requirements

|

||||

|

No

|

Clause

|

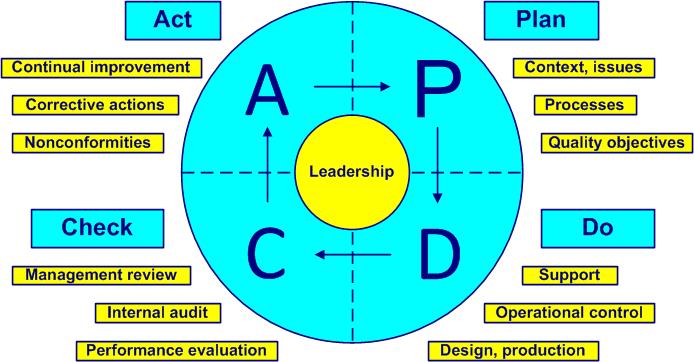

PDCA cycle

|

Requirement No

|

Quantity

|

|

4

|

Context | Plan | 1 ÷ 24 | 24 |

|

5

|

Leadership | Plan, Do, Check, Act |

25 ÷ 50

|

26

|

|

6

|

Planning | Plan |

51 ÷ 77

|

27

|

|

7

|

Support | Do |

78 ÷ 120

|

43

|

|

8

|

Operation | Do |

121 ÷ 248

|

128

|

|

9

|

Performance | Check |

249 ÷ 291

|

43

|

|

10

|

Improvement | Act |

291 ÷ 309

|

18

|

|

Total

|

309

|

|||

Based on IATF 16949 version 2016 the 511 requirements (verb shall) of clauses 4 to 10 are as follows:

|

No

|

Clause

|

PDCA cycle

|

Requirement No

|

Quantity

|

|

4

|

Context | Plan | 1 ÷ 19 | 19 |

|

5

|

Leadership | Plan, Do, Check, Act |

20 ÷ 30

|

11

|

|

6

|

Planning | Plan |

31 ÷ 50

|

20

|

|

7

|

Support | Do |

51 ÷ 133

|

83

|

|

8

|

Operation | Do |

134 ÷ 425

|

292

|

|

9

|

Performance | Check |

426 ÷ 479

|

54

|

|

10

|

Improvement | Act |

480 ÷ 511

|

26

|

|

Total

|

511

|

|||

.jpg)

ISO 9001 2015 requirements

.jpg)

IATF 16949 2016 requirements

The Deming PDCA cycle

Note 1. Any requirement normally begins with "The organization shall...". For simplicity's sake we present the requirements directly, starting with the verb

Note 2. All 309 ISO 9001 version 2015 requirements are on this page

Note 3. We use external provider instead of supplier (conformity with ISO 9001 version 2015)

Note 4. We use documented information to retain instead of record (conformity

|

IATF 16949 version 2016 - Requirements and comments

|

||||

|

No |

Clause, sub-clause |

Requirement |

Comment, link |

|

| 4 |

Context of the organization

|

|||

| 4.1 |

The organization and its context

|

|||

|

|

|

See ISO 9001 version 2015 requirements | ||

| 4.2 |

Needs and expectations of interested parties

|

|

||

|

|

See ISO 9001 version 2015 requirements | |||

| 4.3 |

Scope of the quality management system

|

|

||

|

|

|

See ISO 9001 version 2015 requirements | ||

| 4.3.1 |

Scope of the quality management system

|

supplemental

|

||

|

1

|

4.3.1

|

Include supporting functions, whether on-site or remote, in the scope for the quality management system (QMS) | Such as design centers, corporate headquarters, distribution centers, laboratory | |

|

2

|

4.3.1

|

Justify the exclusions and maintain as documented information | Cf. sub-clause 7.5. The only permitted exclusion relates to the product design and development requirements, cf. sub-clause 8.3 of ISO 9001 | |

|

3

|

4.3.1

|

Never exclude manufacturing process design | It is never authorized | |

| 4.3.2 |

Customer-specific requirements

|

|

||

|

4

|

4.3.2

|

Determine customer-specific requirements | Evaluate these requirements and include them in the scope of the QMS, cf. sub-clause 4.3 | |

| 4.4 |

Quality management system and its processes

|

|

||

| 4.4.1 |

|

|

||

|

|

|

See ISO 9001 version 2015 requirements | ||

| 4.4.1.1 |

Conformance of products and processes

|

|||

|

5

|

4.4.1.1

|

Ensure conformity to all applicable customer, statutory and regulatory requirements | Of all products and manufacturing processes including service parts and those that are outsourced, cf. sub-clause 8.4.2.2 | |

| 4.4.1.2 |

Product safety

|

|

||

|

6

|

4.4.1.2

|

Define documented processes for the management of product-safety related products and manufacturing processes | Cf. sub-clause 7.5 | |

|

7

|

4.4.1.2 a

|

Identify statutory and regulatory product-safety requirements | Cf. sub-clause 8.4.2.2 | |

|

8

|

4.4.1.2 b

|

Notify customer of statutory and regulatory product-safety requirements | Cf. sub-clause 8.4.2.2 | |

|

9

|

4.4.1.2 c

|

Realize special approvals for design FMEA | Cf. 8.3.2.1. Special approval is any safety-related approval | |

|

10

|

4.4.1.2 d

|

Identify product safety-related characteristics | Cf. sub-clause 8.5.2.1 f | |

|

11

|

4.4.1.2 e

|

Identify and control safety-related characteristics of product | At the point of manufacture of these characteristics | |

|

12

|

4.4.1.2 f

|

Realize special approval | Of control plans and process FMEAs | |

|

13

|

4.4.1.2 g

|

Realize reaction plans during monitoring and measurement | Cf. sub-clause 9.1.1.1 | |

|

14

|

4.4.1.2 h

|

Define responsibilities, escalation process and flow of information | Including top management and customer notification | |

|

15

|

4.4.1.2 i

|

Identify training for product-safety related products and associated processes | Cf. sub-clause 7.2 | |

|

16

|

4.4.1.2 j

|

Approve changes of product or process prior to implementation | Evaluate potential effects on product safety from changes. Cf. 8.3.6 | |

|

17

|

4.4.1.2 k

|

Prepare for the transfer of product safety requirements throughout the supply chain | Including customer-designated sources, cf. sub-clause 8.4.1.3 | |

|

18

|

4.4.1.2 l

|

Prepare for product traceability by manufactured lot throughout the supply chain | Cf. sub-clause 8.5.2.1 | |

|

19

|

4.4.1.2 m

|

Learn lessons from new product introduction | Including during the manufacture of the prototypes, cf. Sub-clause 8.3.4.3 | |

| 4.4.2 |

|

|||

|

|

See ISO 9001 version 2015 requirements | |||

| 5 |

Leadership

|

|||

| 5.1 |

Leadership and commitment

|

|||

|

|

5.1.1 |

General

|

|

|

|

|

|

See ISO 9001 version 2015 requirements | ||

|

|

5.1.1.1 |

Corporate responsibility

|

|

|

|

20

|

5.1.1.1

|

Define and implement an anti-bribery policy, an employee code of conduct and an ethics escalation policy | The corporate responsibility concerns everybody in the company and addresses expectations for improved integrity in social matters | |

| 5.1.1.2 |

Process effectiveness and efficiency

|

|

||

|

21

|

5.1.1.2

|

Review the product realization and support processes | On order to evaluate and improve their effectiveness and efficiency. Do not confuse effectiveness and efficiency:

|

|

| 22 |

5.1.1.2

|

Include the results of the process review activities | As input to the management review, cf. sub-clause 9.3.2.1 b and c | |

|

|

5.1.1.3 |

Process owners

|

||

|

23

|

5.1.1.3

|

Assign for each process an owner | This is done exclusively by top management | |

| 24 | 5.1.1.3 | Understand the role and ensure the necessary skills | Each process owner assumes responsibility for its role, cf. sub-clause 7.2 | |

|

|

5.1.2

|

Customer focus

|

|

|

|

|

See ISO 9001 version 2015 requirements | |||

| 5.2 |

Policy

|

|

||

| 5.2.1 |

Establishing the quality policy

|

|

||

|

|

|

See ISO 9001 version 2015 requirements | ||

| 5.2.2 |

Communicating the quality policy

|

|

||

| See ISO 9001 version 2015 requirements | ||||

|

5.3

|

Roles, responsibilities and authorities

|

|

||

|

|

|

See ISO 9001 version 2015 requirements | ||

|

|

5.3.1 |

Roles, responsibilities and authorities

|

supplemental

|

|

|

25

|

5.3.1

|

Assign personnel with the responsibility and authority to ensure that customer requirements are met | This is done exclusively by top management | |

|

26

|

5.3.1

|

Document this mission | Cf. sub-clause 7.5.3.1 | |

|

27

|

5.3.1

|

Include in this mission concrete requirements | Such as selection of special characteristics, determination of quality objectives, implementation of corrective and preventive actions, product design and development, analysis of scorecards | |

|

|

5.3.2 |

Responsibility and authority for product requirements and corrective actions

|

||

|

28

|

5.3.2 a

|

Stop shipment and production to correct quality problems | This authority is given to the quality manager (or the one responsible for meeting product requirements) by top management. When to stop production immediately is impossible isolate the lot and block the shipment | |

| 29 |

5.3.2 b

|

Inform promptly personnel responsible for corrective action of products or processes that do not conform to requirements | In order to avoid shipping nonconforming products. Any product even with a suspicion of nonconformity is immediately identified and isolated. See sub-clauses 8.7 and 10.2 | |

| 30 | 5.3.2 c | Provide all shifts with a responsible person who ensures product conformity | This could be the team leader or another person who has received a delegation | |

|

6

|

Planning

|

|||

| 6.1 |

Actions to address risks and opportunities

|

|

||

| 6.1.1 and 6.1.2 |

|

|

||

|

|

See ISO 9001 version 2015 requirements | |||

| 6.1.2.1 |

Risk analysis

|

|

||

|

31

|

6.1.2.1 | Include in risk analysis lessons learned that can contribute to improvement opportunities | Specific risks associated with the automotive industry such as product recalls, product audits, field returns and repairs, complaints, scrap and rework. Cf. sub-clauses 8.7, 9.2, 10.2 and 10.3 | |

|

32

|

6.1.2.1 | Retain documented information on the results of risk analysis | Cf. sub-clause 7.5.3.1 | |

| 6.1.2.2 |

Preventive action

|

|

||

|

33

|

6.1.2.2 | Determine an implement actions to eliminate the causes of potential nonconformities | In order to prevent their occurrence. Preventive actions are appropriate to the severity of the potential issues | |

|

34

|

6.1.2.2 | Establish a process to lessen the impact of negative effects of risk | Cf. sub-clauses 6.1.1 and 6.1.2 | |

|

35

|

6.1.2.2 a | Include the identification of potential nonconformities | Including identification of their causes | |

|

36

|

6.1.2.2 b | Include the evaluation of the need for action | In order to prevent their occurrence | |

|

37

|

6.1.2.2 c | Include the determination of action needed | Including their implementation | |

|

38

|

6.1.2.2 d | Include the provision of documented information | Relating to action taken, cf. sub-clause 7.5.3.1 | |

|

39

|

6.1.2.2 e | Include the review of the effectiveness of the preventive action taken | Identifying and reviewing similar processes towards prevention | |

|

40

|

6.1.2.2 f | Include the use of lessons learned | In order to prevent the recurrence of the same causes in similar processes, cf. sub-clause 7.1.6 | |

| 6.1.2.3 |

Contingency plans

|

|||

|

41

|

6.1.2.3 a | Identify and evaluate internal and external risks to all manufacturing processes and infrastructure equipment | In order to maintain production output and to ensure that customer requirements are met | |

|

42

|

6.1.2.3 b | Define contingency plans | According to risk and impact to the customer | |

|

43

|

6.1.2.3 c | Prepare contingency plans for continuity of supply | In the event of key equipment failure, interruption from externally provided products, processes and services, natural disasters, fires, utility interruptions, labor shortages or infrastructure disruptions | |

|

44

|

6.1.2.3 d | Include in contingency plans a notification process | In order to inform all stakeholders of the extent and duration of the emergency | |

|

45

|

6.1.2.3 e | Test periodically the contingency plans | In order to evaluate their effectiveness. Simulations, risk analysis | |

|

46

|

6.1.2.3 f | Review contingency plans at least once a year | Include a multidisciplinary team and top management. Perform updates | |

|

47

|

6.1.2.3 g | Retain documented information on emergency plans and revisions | Including the persons who authorized the changes, cf. sub-clause 7.5.3.1 | |

|

48

|

6.1.2.3 | Validate the product after the re-start of production following an emergency | In order to prove that the product continues to meet customer specifications | |

|

6.2

|

Quality objectives and planning to achieve them

|

|

||

|

|

|

See ISO 9001 version 2015 requirements | ||

|

|

6.2.1 and 6.2.2 |

|

|

|

|

|

See ISO 9001 version 2015 requirements | |||

| 6.2.2.1 |

Quality objectives and planning to achieve them

|

supplemental

|

||

|

49

|

6.2.2.1 | Ensure that quality objectives to meet customer requirements are defined, established and maintained | It is the responsibility of top management to ensure that this is done for the functions and processes involved | |

|

50

|

6.2.2.1 | Take into account the results of the review regarding stakeholders | When quality objectives and associated performance indicators are set | |

|

|

6.3 |

Planning of changes

|

||

|

|

See ISO 9001 version 2015 requirements | |||

| 7 |

Support

|

|||

| 7.1 |

Resources

|

|

||

|

|

7.1.1

|

General

|

|

|

|

|

See ISO 9001 version 2015 requirements | |||

| 7.1.2 |

People

|

|

||

|

|

See ISO 9001 version 2015 requirements | |||

|

7.1.3

|

Infrastructure | |||

|

|

See ISO 9001 version 2015 requirements | |||

| 7.1.3.1 |

Plant, facility and equipment planning

|

|

||

|

51

|

7.1.3.1 | Use a multidisciplinary approach to the development and improvement of plant, facility and equipment plans | Including risk identification and risk mitigation methods | |

|

52

|

7.1.3.1 a | Optimize material flow, material handling, value-added use of floor space and control of nonconforming products | Such as "prison" areas to segregate nonconformities | |

|

53

|

7.1.3.1 b | Facilitate synchronous material flow | As applicable | |

|

54

|

7.1.3.1 | Develop and implement methods to evaluate manufacturing feasibility for new product | Or new operations | |

|

55

|

7.1.3.1 | Include in production feasibility assessments capacity planning | Cf. sub-clause 8.1 | |

|

56

|

7.1.3.1 | Ensure that these methods are also applicable for evaluating proposed changes | Regarding existing operations | |

|

57

|

7.1.3.1 | Maintain process effectiveness during changes made throughout manufacturing processes | Including periodic re-evaluation of risk. Cf. sub-clauses 8.5.1.1, 8.5.1.3 and 6.1.1 | |

|

58

|

7.1.3.1 | Include feasibility assessments and capacity planning in the inputs of the management review | Cf. sub-clause 9.3.2.1 Use the Lean approach | |

|

7.1.4

|

Process environment | |||

|

|

See ISO 9001 version 2015 requirements | The requirements of the future ISO 45001 standard will be used for occupational safety aspects | ||

|

|

7.1.4.1 |

Process environment

|

supplemental

|

|

|

59

|

7.1.4.1 | Maintain production premises in a state of order and clean | According to product and process needs | |

| 7.1.5 |

Monitoring and measuring resources

|

|

||

| 7.1.5.1 |

General

|

|

||

|

|

7.1.5.1 | See ISO 9001 version 2015 requirements | ||

| 7.1.5.1.1 |

Measurement system analysis

|

|

||

|

60

|

7.1.5.1.1 | Conduct statistical studies | In order to analyze the variations in the results of each type of inspection, measurement and test equipment system included in the control plan. Cf. sub-clause 8.5.1.1 and annex A | |

|

61

|

7.1.5.1.1 | Use analytical methods and acceptance criteria conform to those in reference manuals | See AIAG publication references in Appendix B: MSA (Measurement Systems Analysis) and SPC (Statistical Process Control). Focus on critical or special characteristics | |

|

62

|

7.1.5.1.1 | Use other analytical methods and acceptance criteria | If approved by the customer | |

|

63

|

7.1.5.1.1 | Retain documented information of customer acceptance of alternative methods | Along with results from alternative measurement systems analysis. Cf. sub-clause 9.1.1.1 | |

| 7.1.5.2 |

Measurement traceability

|

|

||

| See ISO 9001 version 2015 requirements | Use a serial number or another identifier traceable to the device calibration documented information | |||

|

7.1.5.2.1

|

Calibration/verification documented information | |||

|

64

|

7.1.5.2.1 | Use a documented process for managing documented information of calibration and verification | Cf. sub-clause 7.5.3.1 | |

|

65

|

7.1.5.2.1 | Retain documented information related to calibration and verification of gauges and measuring and test equipment | In order to provide evidence of conformity to internal, statutory, regulatory and customer requirements. Cf. sub-clause 7.5.3.1. Including employee-owned, customer-owned or on-site external provider-owned equipment | |

|

66

|

7.1.5.2.1 a | Include in calibration and verification activities and documented information revisions following engineering changes to measurement systems | Cf. sub-clause 8.5.6.1 | |

|

67

|

7.1.5.2.1 b | Include in calibration and verification activities and documented information any out-of-specification readings | Cf. sub-clause 7.5.3.1 | |

|

68

|

7.1.5.2.1 c | Include in calibration and verification activities and documented information an assessment of the risk of the intended use of the product | When an out-of-specification condition occurs | |

|

69

|

7.1.5.2.1 d | Include in calibration and verification activities and documented information the retention of documented information on the validity of previous results and the last and next calibration date | When a measuring or test equipment is found to be out of calibration | |

|

70

|

7.1.5.2.1 e | Include in calibration and verification activities and documented information notification to the customer if suspect product has been shipped | Including suspect material, cf. sub-clause 8.7.1.6 | |

|

71

|

7.1.5.2.1 f | Include in calibration and verification activities and documented information statements of conformity to specification | After calibration or verification | |

|

72

|

7.1.5.2.1 g | Include in calibration and verification activities and documented information verification of the software version as specified | Software used for product and process control | |

|

73

|

7.1.5.2.1 h | Include in calibration and verification activities documented information of the calibration and maintenance activities for all gauging | Including employee-owned, customer-owned or on-site external provider-owned equipment | |

|

74

|

7.1.5.2.1 i | Include in calibration and verification activities and documented information the verification of production-related software used for product and process control | Including software installed on employee-owned, customer-owned or on-site external provider-owned equipment | |

|

|

7.1.5.3 |

Laboratory requirements

|

|

|

| 7.1.5.3.1 |

Internal laboratory

|

|||

|

75

|

7.1.5.3.1 | Describe the scope of the internal laboratory | Including its capability to perform the required inspection, test or calibration services | |

|

76

|

7.1.5.3.1 | Include the laboratory scope description in the QMS documentation | Cf. sub-clause 4.3.1 | |

|

77

|

7.1.5.3.1 a | Specify and implement requirements for adequacy of the technical procedures used | Accreditation to ISO 17025 may be used to demonstrate conformity to this requirement | |

|

78

|

7.1.5.3.1 b | Specify and implement requirements for competency of personnel | Cf. sub-clause 7.2 | |

|

79

|

7.1.5.3.1 c | Specify and implement requirements for testing the product | Accreditation to ISO 17025 may be used to demonstrate conformity to this requirement | |

|

80

|

7.1.5.3.1 d | Specify and implement requirements for capability to perform these services correctly, traceable to the relevant process standard such as ASTM, EN | When a standard does not exist define and implement a methodology to verify measurement system capability | |

|

81

|

7.1.5.3.1 e | Specify and implement requirements for meeting customer requirements, if any | Accreditation to ISO 17025 may be used to demonstrate conformity to this requirement | |

|

82

|

7.1.5.3.1 f | Specify and implement requirements for review of laboratory activity documented information | Cf. sub-clause 7.5.3.1 | |

| 7.1.5.3.2 |

External laboratory

|

|

||

|

83

|

7.1.5.3.2 | Describe the scope of the external laboratory | Including its capability to perform the required inspection, test or calibration services | |

|

84

|

7.1.5.3.2 | Be accredited to ISO 17025 or equivalent | And include within the scope of the accreditation the relevant inspection, test or calibration services | |

| 85 | 7.1.5.3.2 | Include the mark of a national accreditation body | For all calibration certificates or test reports | |

|

86

|

7.1.5.3.2 | Provide evidence that the laboratory is accepted by the customer | Documented information signed by the customer is sufficient | |

|

87

|

7.1.5.3.2 | Perform calibration services by the equipment manufacturer | When a qualified laboratory is not available | |

|

88

|

7.1.5.3.2 | Ensure that internal laboratory requirements are met | When a qualified laboratory is not available | |

|

89

|

7.1.5.3.2 | Obtain government regulatory confirmation, if required | When calibration services other than those provided by qualified laboratories are used | |

| 7.1.6 |

Organizational knowledge

|

|||

| See ISO 9001 version 2015 requirements | ||||

| 7.2 |

Competence

|

|||

| See ISO 9001 version 2015 requirements | ||||

| 7.2.1 |

Competence

|

supplemental

|

||

|

90

|

7.2.1 | Establish and maintain a documented process for identifying training needs | Including awareness and competence related to product and process conformity. Cf. sub-clause 7.5.3.1 | |

|

91

|

7.2.1 | Obtain a qualification for specific tasks | Pay particular attention to the satisfaction of customer requirements | |

| 7.2.2 |

Competence - On-the-job training

|

|

||

|

92

|

7.2.2 | Provide on-the-job training on customer requirements for new or modified responsibilities | When this may affect meeting quality, internal, statutory and regulatory requirements | |

|

93

|

7.2.2 | Include contract or agency personnel for on-the-job training | These persons need more training than others | |

|

94

|

7.2.2 | Adapt the level of detail for on-the-job training with the level of education the personnel possess | And also in relation to the complexity of daily tasks | |

| 95 | 7.2.2 | Inform personnel about the consequences of nonconformity to customer requirements | Cf. sub-clause 8.7.1 | |

| 7.2.3 |

Internal auditor competence

|

|||

|

96

|

7.2.3 | Use a documented process to verify internal auditor competency | Based on customer and ISO 19011 specific requirements | |

|

97

|

7.2.3 | Maintain a list of qualified internal auditors | Cf. sub-clause 7.5.3.1 | |

|

98

|

7.2.3 a | Demonstrate competency for an internal auditor on understanding of the automotive process approach | Risk-based thinking is part of the process approach. Cf. sub-clause 6.1 | |

|

99

|

7.2.3 b | Demonstrate competency for an internal auditor on understanding of applicable customer-specific requirements | Cf. sub-clause 4.3.2 | |

|

100

|

7.2.3 c | Demonstrate competency for an internal auditor on understanding of applicable requirements to the scope of the audit | Cf. sub-clause 9.2.2 | |

|

101

|

7.2.3 d | Demonstrate competency for an internal auditor on understanding of applicable core tool requirements | Cf. annex B of l'IATF 16949 | |

|

102

|

7.2.3 e | Demonstrate competency for an internal auditor on understanding how to plan, conduct, report and close out audit findings | Cf. sub-clause 9.2 and ISO 19011 | |

|

103

|

7.2.3 | Demonstrate technical understanding of the relevant manufacturing process to be audited | Including process risk analysis (process FMEA) and control plan | |

|

104

|

7.2.3 | Demonstrate competence in understanding product requirements | Including using relevant measuring and test equipment in order to verify product conformity | |

|

105

|

7.2.3 | Retain documented information on provided training and trainer competency | In order to acquire the necessary skills | |

|

106

|

7.2.3 f | Maintain and improve internal auditor competence by carrying out regular audits | The number of audits per year per auditor is defined internally | |

|

107

|

7.2.3 g | Maintain and improve internal auditor competence by maintaining knowledge of relevant requirements | Including following internal and external changes (standards, core tools, customer-specific requirements) | |

| 7.2.4 |

Second-party auditor competency

|

|||

|

108

|

7.2.4 | Demonstrate the competence of the auditors undertaking the second-party audits | Training, conducted audits with experienced auditors | |

|

109

|

7.2.4 | Meet customer specific requirements | Cf. sub-clause 4.3.2 | |

|

110

|

7.2.4 a | Demonstrate that second-party auditors possess the competence and understanding of the automotive process approach | Including risk-based thinking | |

|

111

|

7.2.4 b | Demonstrate that second-party auditors possess the competence and understanding of applicable customer-specific requirements | Cf. sub-clause 4.3.2 | |

|

112

|

7.2.4 c | Demonstrate that second-party auditors possess the competence and understanding of applicable requirements to the scope of the audit | Cf. sub-clause 9.2.2 | |

|

113

|

7.2.4 d | Demonstrate that second-party auditors possess the competence and understanding of applicable manufacturing process to be audited | Including PFMEA (process FMEA) and control plan, cf. sub-clause 8.5.1.1 | |

|

114

|

7.2.4 e | Demonstrate that second-party auditors possess the competence and understanding of applicable core tool requirements related to the scope of the audit | Cf. annex B of IATF 16949 | |

|

115

|

7.2.4 f | Demonstrate that second-party auditors possess the competence and understanding of how to plan, conduct, prepare audit reports and clause out audit findings | Cf. sub-clause 9.2 and ISO 19011 | |

| 7.3 | Awareness |

|

||

| See ISO 9001 version 2015 requirements | ||||

| 7.3.1 |

Awareness

|

supplemental

|

||

|

116

|

7.3.1 | Retain documented information on employees' awareness of their impact on product quality, customer requirements and the importance of their activities in achieving, maintaining and improving quality | Including the risks involved for the customer with nonconforming product, cf. sub-clause 8.7.1 | |

| 7.3.2 |

Employee motivation and empowerment

|

|

||

|

117

|

7.3.2 | Maintain a documented process to motivate employees | Especially create an appropriate work environment (which motivates employees and promotes innovation). Cf. sub-clause 7.5.3.1 | |

|

118

|

7.3.2 | Include in the process the promotion of quality and technological awareness throughout the whole organization | Cf. sub-clause 10.3.1 | |

| 7.4 |

Communication

|

|

||

| See ISO 9001 version 2015 requirements | ||||

| 7.5 |

Documented information

|

|||

|

|

7.5.1 |

General

|

|

|

|

|

See ISO 9001 version 2015 requirements | |||

| 7.5.1.1 |

QMS documentation

|

|||

|

119

|

7.5.1.1 | Document the QMS including a quality manual | The quality manual is adapted to the size, culture and complexity of the organization | |

|

120

|

7.5.1.1 | Retain a list of all documents | When the quality manual comprises a series of documents | |

|

121

|

7.5.1.1 a | Include the scope of the QMS | Including the justification for any exclusions, cf. sub-clause 4.3.1 | |

|

122

|

7.5.1.1 b | Include documented processes or a reference to them | Cf. sub-clause 4.4.1.1 | |

|

123

|

7.5.1.1 c | Include processes, their sequence and their interactions | Including outsourced processes, cf. sub-clause 8.4.2. A matrix of how the requirements of the IATF 16949 standard are addressed by the internal processes may be used | |

|

124

|

7.5.1.1 d | Include a document indicating where customer-specific requirements are addressed | Cf. sub-clause 4.3.2 | |

| 7.5.2 |

Creating and updating

|

|||

|

|

See ISO 9001 version 2015 requirements | |||

| 7.5.3 |

Control of documented information

|

|||

| 7.5.3.1 and 7.5.3.2 |

|

|||

| See ISO 9001 version 2015 requirements |

Summary of ISO 9001 v 2015 and IATF 16949 documented information. Documented information to maintain (procedures, documented process):

|

|||

| 7.5.3.2.1 |

Documented information retention

|

|||

|

125

|

7.5.3.2.1 | Define, document and implement a documented information retention policy | Cf. sub-clause 7.5.3.1 | |

|

126

|

7.5.3.2.1 | Satisfy statutory, regulatory, internal and customer requirements | To control all documented information | |

|

127

|

7.5.3.2.1 | Retain documented information for the length of time that the product is active for production and service, plus one calendar year, unless otherwise specified | Documented information relating to production part approvals, tools (including maintenance and ownership), product and process design, purchase orders, contracts and amendments | |

| 7.5.3.2.2 |

Engineering specifications

|

|

||

|

128

|

7.5.3.2.2 | Use a documented process describing the review, distribution and implementation of all customer engineering standards and specifications | Including related revisions and customer schedules. Cf. sub-clause 7.5.3.1 | |

|

129

|

7.5.3.2.2 | Refer to change control requirements when a change of a standard or engineering specification results in a product design change | Cf. sub-clause 8.3.6 | |

|

130

|

7.5.3.2.2 | Refer to change control requirements when a change of a standard or engineering specification results in a product realization process change | Cf. sub-clause 8.5.6.1 | |

|

131

|

7.5.3.2.2 | Retain documented information of the date on which each change is implemented in production | Cf. sub-clause 7.5.3.1 | |

|

132

|

7.5.3.2.2 | Include updated documents | Retain the date of implementation | |

|

133

|

7.5.3.2.2 | Conduct the review within 10 working days | Upon notification of engineering standards or specifications changes | |

| 8 |

Operation

|

Do | ||

| 8.1 |

Operational planning and control

|

|||

| See ISO 9001 version 2015 requirements | ||||

|

|

8.1.1 |

Operational planning and control

|

Supplément

|

|

| 134 | 8.1.1 a | Include in planning for product realization the technical specifications and customer product requirements | Cf. 7.5.3.2.2 | |

| 135 | 8.1.1 b | Include in planning for product realization the logistics requirements | In order to adapt planning to the way the company operates | |

| 136 | 8.1.1 c | Include in planning for product realization the manufacturing feasibility | Cf. sub-clause 8.2.3.1.3 | |

| 137 | 8.1.1 d | Include in planning for product realization the project planning | Cf. sub-clause 8.3.2 | |

| 138 | 8.1.1 e | Include in planning for product realization the acceptance criteria | Cf. sub-clause 8.6.6 | |

| 139 | 8.1.1 | Determine necessary resources needed to achieve conformity of products and services | The activities required are verification, validation, monitoring, measurement, inspection, specific test and acceptance criteria | |

| 8.1.2 |

Confidentiality

|

|

||

| 140 | 8.1.2 | Ensure the confidentiality of customer-contracted products and projects under development | And during implementation | |

| 8.2 |

Requirements for products and services

|

|||

| 8.2.1 |

Customer communication

|

|||

| See ISO 9001 version 2015 requirements | ||||

| 8.2.1.1 |

Customer communication

|

supplemental | ||

| 141 | 8.2.1.1 | Speak in the language agreed with the customer | Concerning written or verbal communication, cf. sub-clause 7.4 | |

| 142 | 8.2.1.1 | Ensure the ability to communicate in a computer language and format specified by the customer | Such as computer-aided design data and electronic data interchange | |

| 8.2.2 |

Requirements for products and services

|

|

||

| See ISO 9001 version 2015 requirements | ||||

|

|

8.2.2.1 |

Requirements for products and services

|

supplemental

|

|

| 143 | 8.2.2.1 | Include recycling and environmental impact requirements | Identify the characteristics of the product and processes | |

| 144 | 8.2.1.1 | Include compliance obligations, applicable government and safety requirements | Related to acquisition, storage, handling, recycling, elimination or disposal of material. Cf. sub-clause 8.2.2 a | |

| 8.2.3 | Review of the requirements for products and services |

|

||

| 8.2.3.1 |

|

|||

| See ISO 9001 version 2015 requirements | ||||

| 8.2.3.1.1 |

Review of the requirements for products and services

|

supplemental

|

||

| 145 | 8.2.3.1.1 | Retain documented evidence (approval) of a customer-authorized concession | Cf. sub-clauses 7.5.3.1 and 8.7.1 | |

| 8.2.3.1.2 |

Customer-designated special characteristics

|

|

||

| 146 | 8.2.3.1.2 | Control the customer's special characteristics | Identification, approval and control, cf. sub-clause 8.2.3.1 | |

| 8.2.3.1.3 | Organization manufacturing feasibility |

|

||

| 147 | 8.2.3.1.3 | Utilize a multidisciplinary approach to conduct an analysis to determine if it is feasible to consistently produce product | That meets all of the engineering and capacity customer requirements, cf. sub-clauses 7.1.3.1 and 8.1.1 | |

| 148 | 8.2.3.1.3 | Conduct a feasibility analysis for any new technology or for any changed process or product design | Cf. sub-clause 8.3.6 | |

| 149 | 8.2.3.1.3 | Validate the ability to make product at the required rate | Through production runs or other method such as simulation | |

| 8.2.3.2 |

|

|

||

| See ISO 9001 version 2015 requirements | ||||

|

|

8.2.4 |

Changes to requirements for products and services

|

|

|

| See ISO 9001 version 2015 requirements | ||||

| 8.3 |

Design and development of products and services

|

|||

| 8.3.1 |

General

|

|||

| See ISO 9001 version 2015 requirements | ||||

| 8.3.1.1 |

Design and development of products and services

|

supplemental

|

||

| 150 | 8.3.1.1 | Focus on error prevention rather than detection | Take into account the requirements of sub-clause 8.3.1 also for processes | |

| 151 | 8.3.1.1 | Document the design and development process | Cf. sub-clause 7.5.3.1 | |

| 8.3.2 | Design and development planning | |||

| See ISO 9001 version 2015 requirements | ||||

| 8.3.2.1 |

Design and development planning

|

supplemental

|

||

| 152 | 8.3.2.1 | Include all affected stakeholders in the design and development planning | Including, as appropriate, the supply chain | |

| 153 | 8.3.2.1 a | Include in the multidisciplinary approach the project management | As APQP, cf. annex B | |

| 154 | 8.3.2.1 b | Include in the multidisciplinary approach the use of alternative product and manufacturing process design activities | Concerning product and manufacturing processes, cf. annex B | |

| 155 | 8.3.2.1 c | Include in the multidisciplinary approach the development and review of product design risk analysis and actions to reduce potential risks | Such as product FMEA | |

| 156 | 8.3.2.1 d | Include in the multidisciplinary approach the development and review of manufacturing process risk analysis | Such as PFMEA, process flows, control plans | |

| 8.3.2.2 |

Product design skills

|

|

||

| 157 | 8.3.2.2 | Ensure that personnel are competent to achieve design requirements | And control applicable product design tools and techniques | |

| 158 | 8.3.2.2 | Identify applicable tools and techniques for product design | Such as digitized mathematically based data | |

| 8.3.2.3 |

Development of products with embedded software

|

|

||

| 159 | 8.3.2.3 | Use a process for quality assurance for products with internally embedded software | Concerning one or more embedded systems by product | |

| 160 | 8.3.2.3 | Assess the software development process | Cf. sub-clauses 8.3.3.1 h, 8.3.4.2, and 8.4.2.3.1 | |

| 161 | 8.3.2.3 | Retain documented information of a software development capability self-assessment | Using prioritization based on risk and potential impact to the customer. Cf. sub-clause 7.5.3.1 | |

| 162 | 8.3.2.3 | Include software development within the internal audit program | Cf. sub-clause 9.2.2.1 | |

| 8.3.3 |

Design and development inputs

|

|||

| See ISO 9001 version 2015 requirements | ||||

| 8.3.3.1 |

Product design input

|

|

||

| 163 | 8.3.3.1 | Identify, document and review product design input requirements | After each contract review. Cf. sub-clause 7.5.3.1 | |

| 164 | 8.3.3.1 a | Include in product design input requirements the product specifications and special characteristics | Cf. sub-clause 8.3.3.3 | |

| 165 | 8.3.3.1 b | Include in product design input requirements the boundary and interface requirements | Limits not to exceed and links to other products and assemblies | |

| 166 | 8.3.3.1 c | Include in product design input requirements the identification, traceability and packaging | Cf. sub-clauses 8.5.2 and 8.5.4.1 | |

| 167 | 8.3.3.1 d | Include in product design input requirements the consideration of design alternatives | Such as compromise curves | |

| 168 | 8.3.3.1 e | Include in product design input requirements the assessment of risks | Including the ability to mitigate the risks and the feasibility analysis, cf. sub-clauses 6.1 and 8.2.3.1.3 | |

| 169 | 8.3.3.1 f | Include in product design input requirements the objectives for product conformity | Such as preservation, reliability, durability, serviceability, health, safety, environmental, development timing and cost | |

| 170 | 8.3.3.1 g | Include in product design input requirements the applicable statutory and regulatory requirements | Of the customer-identified country of destination, if provided | |

| 171 | 8.3.3.1 h | Include in product design input requirements the embedded software requirements | Such as requirements related to predictability, analyzability, verifiability and comprehensibility. Cf. sub-clause 8.3.2.3 | |

| 172 | 8.3.3.1 | Ensure a process to deploy appropriate information | Such as gained from previous design projects, benchmarking, feedback, field data | |

| 8.3.3.2 |

Manufacturing process design input

|

|

||

| 173 | 8.3.3.2 | Identify, document and review manufacturing process design input requirements | Cf. sub-clause 7.5.3.1 | |

| 174 | 8.3.3.2 a | Include in process design input the product design output data | Including special characteristics | |

| 175 | 8.3.3.2 b | Include in process design input the objectives for performance | Such as productivity, process capability, timing and costs | |

| 176 | 8.3.3.2 c | Include in process design input the manufacturing technologies alternatives | Bench marking | |

| 177 | 8.3.3.2 d | Include in process design input the customer requirements | Cf. sub-clause 4.3.2 | |

| 179 | 8.3.3.2 e | Include in process design input the experiences acquired | Such as previous design projects, benchmarking, feedback | |

| 180 | 8.3.3.2 f | Include in process design input the new materials | That will be used for new products | |

| 181 | 8.3.3.2 g | Include in process design input the product handling and ergonomic requirements | Cf. sub-clause 7.1.4 | |

| 182 | 8.3.3.2 h | Include in process design input design for manufacturing and design for assembly | Cf. annex B | |

| 183 | 8.3.3.2 | Include the use of appropriate error-proofing methods | Cf. sub-clause 10.2.4 | |

| 8.3.3.3 |

Special characteristics

|

|||

| 184 | 8.3.3.3 | Use a multidisciplinary approach to establish, document and implement a process to identify special characteristics | Cf. sub-clause 7.5.3.1. Taking into account the special characteristics resulting from the risk analysis | |

| 185 | 8.3.3.3 a | Include all special characteristics and identify them with special markings in all concerned documents | Such as drawings, FMEAs, control plans, work instructions | |

| 186 | 8.3.3.3 b | Control special characteristics of products and processes | Development of control and monitoring strategies throughout the production chain | |

| 187 | 8.3.3.3 c | Obtain customer-specified approvals | When required | |

| 188 | 8.3.3.3 d | Observe customer-specified definitions and symbols | Or use equivalent symbols defined in a conversation table | |

| 189 | 8.3.3.3 d | Submit the symbol conversion table to the customer for approval | If required | |

| 8.3.4 |

Design and development controls

|

|||

| See ISO 9001 version 2015 requirements | ||||

| 8.3.4.1 |

Monitoring

|

|

||

| 190 | 8.3.4.1 | Define, analyze and report summary of measurements as an input to management review, at specified stages during design and development of products and processes | Cf. sub-clause 9.3.2.1. Risks are included, where appropriate, related to quality, costs, development times and other measures | |

| 191 | 8.3.4.1 | Report to the customer, when required, measurements of the product and process development activity, at specified stages | The stages are specified by the customer or decided with his consent | |

| 8.3.4.2 |

Design and development validation

|

|

||

| 192 | 8.3.4.2 | Perform design and development validation in accordance with customer and applicable industry standards | Including any applicable industry and governmental agency-issued regulatory standard | |

| 193 | 8.3.4.2 | Plan and meet deadlines for design and development validation | If possible, follow the schedule specified by the customer | |

| 194 | 8.3.4.2 | Include in the validation evaluation of the interaction of the product with the system of the final customer's product | Where contractually agreed with the customer, including embedded software, cf. sub-clause 8.3.2.3 | |

| 8.3.4.3 |

Prototype program

|

|||

| 195 | 8.3.4.3 | Ensure a prototype program, when required by the customer | Including a prototype control plan, cf. sub-clause 8.5.1.1 | |

| 196 | 8.3.4.3 | Use, whenever possible, the same external providers, tooling and manufacturing processes as will be used in production | In order not to have surprises | |

| 197 | 8.3.4.3 | Monitor all performance-testing activities for timely completion | And for conformity | |

| 198 | 8.3.4.3 | Include in the scope of the QMS, when services are outsourced, the type and extent of control of outsourced services | Cf. sub-clause 8.4 | |

| 8.3.4.4 |

Product approval process

|

|

||

| 199 | 8.3.4.4 | Establish, implement and maintain a product and manufacturing approval process conforming to customer requirements | Verify the manufacturing process before product approval, review the effectiveness of the process | |

| 200 | 8.3.4.4 | Approve externally provided products and services | Prior to submission of part approval to the customer. Cf. sub-clause 8.4.3 | |

| 201 | 8.3.4.4 | Obtain documented product approval prior to shipment | If required by the customer | |

| 202 | 8.3.4.4 | Retain documented information of such approval | Cf. sub-clause 7.5.3.1 | |

| 8.3.5 | Design and development outputs |

|

||

| See ISO 9001 version 2015 requirements | ||||

| 8.3.5.1 |

Design and development outputs

|

supplemental

|

||

| 203 | 8.3.5.1 | Express product design output against design input requirements | In terms that can be verified and validated | |

| 204 | 8.3.5.1 a | Include in the product design output the design risk analysis | Such as FMEA and problems resolved through a compromise process | |

| 205 | 8.3.5.1 b | Include in the product design output the reliability study results | Cf. sub-clause 8.3.5.2 l | |

| 206 | 8.3.5.1 c | Include in the product design output the product special characteristics | Cf. sub-clause 8.3.3.3 | |

| 207 | 8.3.5.1 d | Include in the product design output the results of product design error-proofing | Cf. sub-clause 10.2.4 and annex B. Such as DFSS (Design for Six Sigma), DFMA (Design for Manufacture and Assembly), FTA (Fault Tree Analysis) | |

| 208 | 8.3.5.1 e | Include in the product design output the product definition | Such as 3D models, technical data packages, product manufacturing information, GD&T (geometric dimensioning & tolerance) | |

| 209 | 8.3.5.1 f | Include in the product design output the 2D drawings | Such as product manufacturing information, GD&T (geometric dimensioning & tolerance) | |

| 210 | 8.3.5.1 g | Include in the product design output the product design review results | Which may be included as inputs to the management review, cf. Sub-clause 9.3.2.1 | |

| 212 | 8.3.5.1 h | Include in the product design output the diagnostic guidelines and repair instructions | In order to realize diagnostics, repairs and replacements | |

| 213 | 8.3.5.1 i | Include in the product design output the service part requirements | Including instructions, methods, tooling | |

| 214 | 8.3.5.1 j | Include in the product design output the packaging and labeling requirements | All shipping information | |

| 8.3.5.2 |

Manufacturing process design output

|

|||

| 215 | 8.3.5.2 | Document the manufacturing process design output | In order to verify these outputs against inputs | |

| 216 | 8.3.5.2 | Verify the outputs against manufacturing process design input requirements | Concerning manufacturing process design | |

| 217 | 8.3.5.2 a | Include in the manufacturing process design output the specifications and drawings | Necessary to manufacturing | |

| 218 | 8.3.5.2 b | Include in the manufacturing process design output the special characteristics | Cf. sub-clause 8.3.3.3 | |

| 219 | 8.3.5.2 c | Include in the manufacturing process design output the identification of process input variables | Input variables that impact chracteristics | |

| 220 | 8.3.5.2 d | Include in the manufacturing process design output the tooling and equipment for production and control | Including capability studies of equipment and processes | |

| 221 | 8.3.5.2 e | Include in the manufacturing process design output the manufacturing process flow charts and layout | In order to show the links between product, process, tooling, raw material and inspection | |

| 222 | 8.3.5.2 f | Include in the manufacturing process design output the capacity analysis | Cf. sub-clause 8.2.3.1.3 | |

| 223 | 8.3.5.2 g | Include in the manufacturing process design output the manufacturing process FMEA | Cf. sub-clause 8.5.1.1 | |

| 224 | 8.3.5.2 h | Include in the manufacturing process design output the maintenance | Planning, instructions, cf. sub-clause 8.5.1.5 | |

| 225 | 8.3.5.2 i | Include in the manufacturing process design output the control plan | Cf. annex A | |

| 226 | 8.3.5.2 j | Include in the manufacturing process design output the standardized work and work instructions | And any other necessary manufacturing document | |

| 227 | 8.3.5.2 k | Include in the manufacturing process design output the process approval acceptance criteria | In order to validate the processes | |

| 227 | 8.3.5.2 l | Include in the manufacturing process design output the production data | Concerning quality, reliability, maintainability and measurability | |

| 228 | 8.3.5.2 m | Include in the manufacturing process design output the results of error-proofing identification and verification | As appropriate. Cf. sub-clause 10.2.4 | |

| 229 | 8.3.5.2 n | Include in the manufacturing process design output the cases of product and process nonconformities | Such as feedback, methods of rapid detection and solving | |

| 8.3.6 |

Design and development changes

|

|||

| See ISO 9001 version 2015 requirements | ||||

| 8.3.6.1 |

Design and development changes

|

supplemental

|

||

| 230 | 8.3.6.1 | Evaluate all design changes after initial product approval for potential impact on fit, form, function, performance or durability | Including those proposed internally or by external providers | |

| 231 | 8.3.6.1 | Validate and approve these changes prior to production implementation | Taking into account customer requirements | |

| 232 | 8.3.6.1 | Obtain customer documented approval or a documented concession prior to production implementation | If required by the customer | |

| 233 | 8.3.6.1 | Document the revision level of software and hardware for products with embedded software | When changes are retained, cf. sub-clause 7.5.3.1 | |

| 8.4 |

External providers

|

|||

| 8.4.1 |

General

|

|||

| See ISO 9001 version 2015 requirements | ||||

| 8.4.1.1 |

General

|

supplemental

|

||

| 234 | 8.4.1.1 | Include in the definition of externally provided products, processes and services all products and services that affect customer requirements | Such as sub-assembly, sorting, rework and calibration | |

| 8.4.1.2 |

External provider selection process

|

|

||

| 235 | 8.4.1.2 | Define a documented external provider selection process | Cf. sub-clause 8.4.1 | |

| 236 | 8.4.1.2 a | Include in the selection process an assessment of external providers | Compared to product and supply conformity | |

| 237 | 8.4.1.2 b | Include in the selection process the performance | Compared to quality and delivery performance | |

| 238 | 8.4.1.2 c | Include in the selection process an evaluation of the external provider QMS | Cf. sub-clause 8.4.2.3 | |

| 239 | 8.4.1.2 d | Include in the selection process multidisciplinary decision making | As representatives of purchasing, quality and logistics departments | |

| 240 | 8.4.1.2 e | Include in the selection process an assessment of software development capabilities | Cf. sub-clause 8.4.2.3.1 | |

| 241 | 8.4.1.2 | Include in the external provider selection other criteria to consider such as volume of automotive business | As quantity or as percentage | |

| 242 | 8.4.1.2 | Include in the external provider selection other criteria to consider such as financial stability | Historical and competitive analysis | |

| 243 | 8.4.1.2 | Include in the external provider selection other criteria to consider such as purchased product, material or service complexity | Be careful because sometimes some simple things are very difficult to achieve | |

| 244 | 8.4.1.2 | Include in the external provider selection other criteria to consider such as required technology | Concern the product or the process | |

| 245 | 8.4.1.2 | Include in the external provider selection other criteria to consider such as adequacy of available resources | Such as people, equipment and infrastructure | |

| 246 | 8.4.1.2 | Include in the external provider selection other criteria to consider such as design and development capabilities | Including project management | |

| 247 | 8.4.1.2 | Include in the external provider selection other criteria to consider such as manufacturing capability | Very important criterion | |

| 248 | 8.4.1.2 | Include in the external provider selection other criteria to consider such as change management process | Cf. sub-clause 8.5.6 | |

| 249 | 8.4.1.2 | Include in the external provider selection other criteria to consider such as business continuity planning | Such as disaster preparedness or contingency planning | |

| 250 | 8.4.1.2 | Include in the external provider selection other criteria to consider such as logistic process | Management of normal and crisis situations | |

| 251 | 8.4.1.2 | Include in the external provider selection other criteria to consider such as customer service | Management of nonconforming product and crisis situations | |

| 8.4.1.3 |

Customer-directed sources

|

|

||

| 252 | 8.4.1.3 | Purchase products, materials or services from customer-directed sources | These are customer-designated (approved) external providers | |

| 253 | 8.4.1.3 | Apply the requirements of sub-clause 8.4 unless otherwise agreed in the contract with the customer | Cf. sub-clause 8.4 | |

| 8.4.2 |

Type and extent of control

|

|||

| See ISO 9001 version 2015 requirements | ||||

| 8.4.2.1 |

Type and extent of control

|

supplemental

|

||

| 254 | 8.4.2.1 | Define a documented process to identify outsourced processes | Select the type and extent of inspections to verify conformity of products, processes and services provided by external providers | |

| 255 | 8.4.2.1 | Include the criteria and actions to escalate or reduce the type and extent of controls | Based on external provider performance and associated risks | |

| 8.4.2.2 |

Statutory and regulatory requirements

|

|

||

| 256 | 8.4.2.2 | Document a process to ensure that purchased products, processes and services conform to the current applicable statutory and regulatory requirements in the country of customer receipt, shipment and destination | Cf. sub-clause 7.5.3.1 | |

| 257 | 8.4.2.2 | Implement and maintain as defined by customer special controls for certain products with statutory and regulatory requirements | Including if these inspections are performed at external provider's premises | |

| 8.4.2.3 |

External provider QMS development

|

|

||

| 258 | 8.4.2.3 | Require the external providers to develop, implement and improve an ISO 9001-certified QMS by following the sequence below | And to explain that the ultimate objective is becoming IATF 16949 certified, unless otherwise authorized by the customer | |

| 259 | 8.4.2.3 a | Apply conformity to ISO 9001 through second-party audits | Cf. sub-clause 7.2.4 | |

| 260 | 8.4.2.3 b | Obtain certification to ISO 9001 through third-party audits | Tis must be done by a certification body recognized IAF MLA (International Accreditation Forum Multilateral Recognition Arrangement) | |

| 261 | 8.4.2.3 c | Apply certification to ISO 9001 completed by conformity to other customer-defined QMS requirements | Such as requirements announced in the MAQMSR (Minimum Automotive Management System Requirements) or another equivalent standard | |

| 262 | 8.4.2.3 d | Obtain certification to ISO 9001 with conformity to IATF 16949 through second-party audits | Cf. sub-clause 7.2.4 | |

| 263 | 8.4.2.3 e | Obtain certification to IATF 16949 through third-party audits | This must be issued by an IATF-recognized certification body | |

| 8.4.2.3.1 |

Automotive product-related software (embedded software)

|

|

||

| 264 | 8.4.2.3.1 | Require the external providers of automotive product-related software or embedded software to implement and maintain a specific process | In order to ensure product software quality | |

| 265 | 8.4.2.3.1 | Utilize a software development assessment methodology | In order to assess the external provider software development process | |

| 266 | 8.4.2.3.1 | Require the external providers to retain documented information of their self-assessment capability to develop software | Using prioritization based on risk and potential impact to the customer | |

| 8.4.2.4 |

External provider monitoring

|

|||

| 267 | 8.4.2.4 | Identify a documented process and criteria to evaluate the performance of external providers | And introduce improvement actions. Cf. sub-clause 7.5.3.1 | |

| 268 | 8.4.2.4 | Ensure conformity with internal and customer requirements for all that is provided by external providers | Such as products, processes and services | |

| 269 | 8.4.2.4 a | Monitor performance indicators of external providers such as conformity of delivered products | Cf. sub-clause 8.4.1.1 | |

| 270 | 8.4.2.4 b | Monitor performance indicators of external providers such as customer disruptions at the receiving plant | Including yard holds and stop ships | |

| 271 | 8.4.2.4 c | Monitor performance indicators of external providers such as delivery schedule | Quantity, quality, deadlines | |

| 272 | 8.4.2.4 d | Monitor performance indicators of external providers such as number of occurrences of premium freight | Such as abnormal deliveries (by taxi, by airplane, by helicopter) | |

| 273 | 8.4.2.4 e | Include customer notifications for special status | Root causes related to quality or delivery issues of external providers | |

| 274 | 8.4.2.4 f | Include dealer returns, warranty | Including field actions and recalls | |

| 8.4.2.4.1 |

Second-party audit

|

|

||

| 275 | 8.4.2.4.1 | Include a second-party audit process | In external provider's management. Cf. the IATF auditor guide and ISO 19011 | |

| 276 | 8.4.2.4.1 a | Use second-party audits for risk assessment | Related to the external provider | |

| 277 | 8.4.2.4.1 b | Use second-party audits for external provider monitoring | Regular monitoring of its performance | |

| 278 | 8.4.2.4.1 c | Use second-party audits for development of external provider QMS | Cf. sub-clause 8.4.2.3 | |

| 279 | 8.4.2.4.1 d | Use second-party audits for product audits | Cf. sub-clause 9.2.2.4 | |

| 280 | 8.4.2.4.1 e | Use second-party audits for process audits | Cf. sub-clause 9.2.2.3 | |

| 281 | 8.4.2.4.1 | Document the criteria for determining the need, type, frequency and scope of second-party audits | Based on a risk analysis, the external provider's safety / regulatory performance and the level of development of its QMS | |

| 282 | 8.4.2.4.1 | Retain documented information of the second-party audit reports | Cf. sub-clause 7.5.3.1 | |

| 283 | 8.4.2.4.1 | Adopt an approach consistent with the automotive process approach | When the audit assesses the QMS of external providers | |

| 8.4.2.5 |

External provider development

|

|

||

| 284 | 8.4.2.5 | Determine the development actions for active external providers | Including the priority, type, extent and timing of actions. Consider short and long term goals | |

| 285 | 8.4.2.5 a | Take into account performance issues | Cf. sub-clause 8.4.2.4 | |

| 286 | 8.4.2.5 b | Take into account second-party audit findings | Cf. sub-clause 8.4.2.4.1 | |

| 287 | 8.4.2.5 c | Take into account third-party QMS certification status | Cf. sub-clause 8.4.2.3 | |

| 288 | 8.4.2.5 d | Take into account risk analysis | Cf. sub-clause 6.1.2.1 | |

| 289 | 8.4.2.5 | Implement actions necessary to resolve open performance issues | And seize opportunities for continual improvement | |

| 8.4.3 |

Information for external providers

|

|||

| See ISO 9001 version 2015 requirements | ||||

| 8.4.3.1 |

Information for external providers

|

supplemental

|

||

| 290 | 8.4.3.1 | Pass down all applicable statutory and regulatory requirements and special product and process characteristics to external providers | Cf. sub-clauses 8.4.2.2 and 8.3.3.3 | |

| 291 | 8.4.3.1 | Require the external providers to cascade all applicable requirements down the supply chain | Concerning the points of manufacture | |

| 8.5 |

Production and service provision

|

|||

| 8.5.1 |

Control of production and service provision

|

|||

| See ISO 9001 version 2015 requirements | ||||

| 8.5.1.1 |

Control plan

|

|||

| 292 | 8.5.1.1 | Develop control plans at all levels (system, subsystem, component and material including bulk materials) | Cf. annex A | |

| 293 | 8.5.1.1 | Use family control plans | For bulk material and similar parts (using a common manufacturing process) | |

| 294 | 8.5.1.1 | Develop control plans for pre-launch and production with information from the design risk analysis, process flow diagram and process risk analysis outputs | Such as FMEA. Cf. sub-clause 8.3.2.1 | |

| 295 | 8.5.1.1 | Provide, if requested by the customer, data collected during execution of either the pre-launch or production control plans | Cf. sub-clause 7.5.3.1 | |

| 296 | 8.5.1.1 a | Include in the control plan controls used for the manufacturing process control | Including verification of job set-ups | |

| 297 | 8.5.1.1 b | Include in the control plan first-off/last-off part validation | As applicable | |

| 298 | 8.5.1.1 c | Include in the control plan methods for monitoring of control | In order to verify the special characteristics, cf. annex A | |

| 299 | 8.5.1.1 d | Include in the control plan customer-required information | If any | |

| 300 | 8.5.1.1 e | Include in the control plan when initiating a specified reaction plan | When nonconforming product is detected, the process becomes statistically unstable or not statistically capable. Cf. annex A | |

| 301 | 8.5.1.1 f | Review and update control plans when the organization determines it has shipped nonconforming product to the customer | Cf. sub-clause 8.7.1 | |

| 302 | 8.5.1.1 g | Review and update control plans when any change occurs | Affecting product, manufacturing process, measurement, logistics, supply sources, production volume, or risks analysis. Cf. annex A | |

| 303 | 8.5.1.1 h | Review and update control plans after a customer complaint and implementation of the associated corrective action | Cf. sub-clause 10.2 | |

| 304 | 8.5.1.1 i | Review and update control plans at a set frequency | Based on a risk analysis | |

| 305 | 8.5.1.1 | Obtain customer approval after review of the control plan | If required by the customer | |

| 8.5.1.2 |

Standardized work - operator instructions and visual standards

|

|||

| 306 | 8.5.1.2 a | Ensure that standardized work documents are communicated to and understand by the employees | Who are responsible for performing the work | |

| 307 | 8.5.1.2 b | Ensure that standardized work documents are legible | Cf. sub-clause 7.5.2 | |

| 308 | 8.5.1.2 c | Ensure that standardized work documents are presented in the language understood by those responsible to follow them | Cf. sub-clause 7.5.2 | |

| 309 | 8.5.1.2 d | Ensure that standardized work documents are accessible | At the designed work areas | |

| 310 | 8.5.1.2 | Include in standardized work documents rules for operator safety | Cf. sub-clause 7.1 | |

| 8.5.1.3 |

Verification of job set-ups

|

|

||

| 311 | 8.5.1.3 a | Verify job set-ups | It is the responsibility of the team leader, during initial start-up, modification of equipment or change of production family | |

| 312 | 8.5.1.3 b | Maintain documented information for job set-ups | For set-up personnel. Cf. sub-clause 7.5.3.1 | |

| 313 | 8.5.1.3 c | Use statistical methods of verification | Where applicable. Cf. sub-clause 9.1.1.2 | |

| 314 | 8.5.1.3 d | Perform first-off/last-off part validation, as applicable | Where appropriate retain first-off parts and last-off parts for comparison. Cf. sub-clause 8.5.1.1 b | |

| 315 | 8.5.1.3 e | Retain documented information of process and product approval | Following set-up and first-off (last-off) part validation, cf. sub-clause 7.5.3.1 | |

|

|

8.5.1.4 |

Verification after shutdown

|

|

|

| 316 | 8.5.1.4 | Define and implement the necessary actions to ensure product conformity | After a production shutdown period. Lessons learned and best practices | |

| 8.5.1.5 |

Total productive maintenance

|

|||

| 317 | 8.5.1.5 | Develop, implement and maintain a documented total productive maintenance system | For all manufacturing processes. Cf. annex B | |

| 318 | 8.5.1.5 a | Identify the necessary process equipment | In order to produce conforming product at the required volume | |

| 319 | 8.5.1.5 b | Manage the availability of replacements parts | For the necessary process equipment | |

| 320 | 8.5.1.5 c | Provide necessary maintenance personnel | For machine, equipment and facility maintenance | |

| 321 | 8.5.1.5 d | Manage packaging and preservation of equipment, tooling and gauging | Cf. sub-clause 8.5.4 | |

| 322 | 8.5.1.5 e | Include applicable customer-specific requirements | Cf. sub-clause 4.3.2 | |

| 323 | 8.5.1.5 f | Determine documented maintenance objectives | Such as OEE (Overall Equipment Effectiveness), MTBF (Mean Time Between Failure), MTTR ( Mean Time To Repair) and preventive maintenance compliance metrics | |

| 324 | 8.5.1.5 f | Use performance to the maintenance objectives as input to management review | Cf. sub-clause 9.3.2 | |

| 325 | 8.5.1.5 g | Review maintenance plan and objectives | Regularly | |

| 326 | 8.5.1.5 g | Document corrective actions where objectives are not achieved | Cf. sub-clause 10.2 | |

| 327 | 8.5.1.5 h | Use preventive maintenance methods | To avoid the causes of malfunctions. "A little prevention is better than a lot of healing." English proverb | |

| 328 | 8.5.1.5 i | Use predictive maintenance methods | To monitor periodically and plan actions. As applicable | |

| 329 | 8.5.1.5 j | Include periodic overhaul | In the maintenance plan | |

| 8.5.1.6 |

Management of tooling and equipment

|

|||

| 330 | 8.5.1.6 | Provide resources for tool and gauge design, fabrication and verification activities | For production and service materials and for bulk materials, as applicable | |

| 331 | 8.5.1.6 a | Include maintenance and repair facilities and personnel in tooling management | Cf. sub-clauses 7.1.2 and 7.1.4 | |

| 332 | 8.5.1.6 b | Include storage and recovery in tooling management | Cf. sub-clause 7.1.3 | |

| 333 | 8.5.1.6 c | Include set-up in tooling management | Cf. sub-clause 7.1.3 | |

| 334 | 8.5.1.6 d | Include tool-change programs in tooling management | For perishable tools | |

| 335 | 8.5.1.6 e | Include tool design modification documentation in tooling management | Including engineering change level of the product | |

| 336 | 8.5.1.6 f | Include tool modification in tooling management | Including revision of documentation | |

| 337 | 8.5.1.6 g | Include tool identification in tooling management | Such as serial or asset number, its usage status (production, repair or disposal), ownership and location | |

| 338 | 8.5.1.6 | Verify that customer-owned tools and equipment are permanently marked in a visible location | In order to determine ownership and application of each item, cf. sub-clause 8.5.3 | |

| 339 | 8.5.1.6 | Monitor these activities when they are outsourced | Cf. sub-clause 8.4.1 | |

|

|

8.5.1.7 |

Production scheduling

|

|

|

| 340 | 8.5.1.7 | Ensure that production is scheduled in order to meet customer orders | Including just-in-time (JIT) production. Use lessons learned | |

| 341 | 8.5.1.7 | Ensure that an information system permits access to production data | At key stages of the process and is order driven | |

| 342 | 8.5.1.7 | include relevant planning information during production scheduling | Such as customer orders, delivery performance of external providers, capacity, shared loading, lead time, inventory level, preventive maintenance and calibration. In other words a robust feasibility review process regarding production scheduling | |

| 8.5.2 |

Identification and traceability

|

|||

| See ISO 9001 version 2015 requirements | ||||

| 8.5.2.1 |

Identification and traceability

|

supplemental

|

||

| 343 | 8.5.2.1 | Identify clear start and stop points for product received by the customer with the help of traceability | Product that may present a risk of nonconformity or safety, based on lessons learned | |

| 344 | 8.5.2.1 | Implement identification and traceability processes | Processes described in the requirements below | |

| 345 | 8.5.2.1 | Conduct an analysis of internal, customer and regulatory traceability requirements | Related to traceability applicable to automotive products | |

| 346 | 8.5.2.1 | Develop and document traceability plans | Based on the levels of risk or failure severity for employees, customers and consumers, cf. sub-clause 7.5.3.1 | |

| 347 | 8.5.2.1 | Define traceability systems, processes and methods | By product, process and manufacturing location | |

| 348 | 8.5.2.1 a | Identify nonconforming or suspect product | Cf. sub-clauses 8.7.1 and 8.7.1.3 | |

| 349 | 8.5.2.1 b | Segregate nonconforming or suspect product | Red boxes and "prison" | |

| 350 | 8.5.2.1 c | Meet customer or regulatory response time requirements | Concerning notification response | |

| 351 | 8.5.2.1 d | Retain documented information in appropriate format | In accordance with the reaction time constraints, cf. sub-clause 7.5.3.1 | |

| 352 | 8.5.2.1 e | Ensure serialized identification of individual products | If specified by the customer or regulatory standards | |

| 353 | 8.5.2.1 f | Extend identification and traceability requirements to products with safety / regulatory characteristics | Concerning externally provided products | |

| 8.5.3 |

Property belonging to customers or external providers

|

|||

| See ISO 9001 version 2015 requirements | ||||

| 8.5.4 |

Preservation

|

|||

| See ISO 9001 version 2015 requirements | ||||

| 8.5.4.1 |

Preservation

|

supplemental

|

||

| 354 | 8.5.4.1 | Include in preservation identification, handling, control of contamination, packaging, storage, transmission or transport and protection | Concerning production and service provision outputs | |

| 355 | 8.5.4.1 | Apply preservation to materials and components from external or internal providers | From the receipt, through processing until acceptance by the customer | |

| 356 | 8.5.4.1 | Assess, at appropriate planned intervals, the condition of product in stock, the storage container and environment | In order to detect any deterioration | |

| 357 | 8.5.4.1 | Use an inventory management system to optimize inventory turns and ensure stock rotation | Such as FIFO (first in, first out) | |

| 358 | 8.5.4.1 | Ensure that obsolete product is identified and controlled in a manner similar to that of nonconforming product | Cf. sub-clause 8.7.1 | |

| 359 | 8.5.4.1 | Comply with customer requirements | Concerning preservation, packaging, labeling and shipping | |

| 8.5.5 |

Post-delivery activities

|

|||

| See ISO 9001 version 2015 requirements | ||||

| 8.5.5.1 |

Feedback of information from service

|

|

||

| 360 | 8.5.5.1 | Establish, implement and maintain a post-delivery service communication process | Cf. sub-clause 10.2.6 | |

| 8.5.5.2 |