ISO 22000 food safety management system requirements version 2018

15/10/2023

Quiz requirements ISO 22000 version 2018 You want to familiarize yourself with the structure of the standard, identify and understand the requirements of ISO 22000 version 2018, then it's up to you to play!

The "ISO 22000 version 2018 Requirements" quiz will help you understand the main requirements of the standard.

The questions (requirements) included in this quiz are 132 of the 452 in the standard, but don't worry. These requirements are among the most important. So do not hesitate to learn in a fun way!

Do not think you can finish this quiz in less than an hour, or even two hours, unless of course you are a little genius!

Some news about ISO 22000 version 2018

The course T 20v18 ISO 22000 version 2018 readiness and its free demo without registration

The course T 40v18 ISO 22000 version 2018 internal audit and its free demo without registration

The T 70v18 training package ISO 22000 version 2018 readiness and internal audit

The 452 ISO 22000 version 2018 requirements (verb shall) of clauses 4 to 10 are as follows:

|

No

|

Clause

|

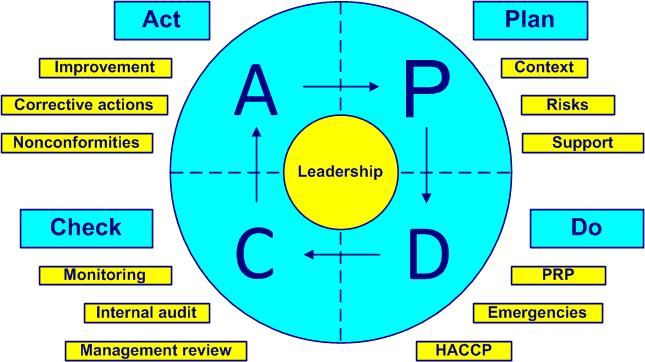

PDCA cycle

|

Requirement No

|

Quantity

|

|

4

|

Context | Plan | 1 ÷ 13 | 13 |

|

5

|

Leadership | Plan, Do, Check, Act |

14 ÷ 40

|

27

|

|

6

|

Planning | Plan |

41 ÷ 68

|

28

|

|

7

|

Support | Do |

69 ÷ 140

|

72

|

|

8

|

Operation | Do |

141 ÷ 376

|

236

|

|

9

|

Performance | Check |

377 ÷ 422

|

46

|

|

10

|

Improvement | Act |

423 ÷ 452

|

30

|

|

Total

|

452

|

|||

.jpg)

ISO 22000 version 2018 requirements

The Deming PDCA cycle

Note. Any requirement normally begins with "The organization shall...". For simplicity's sake we present the requirements directly, starting with the verb

|

No

|

Clause, sub-clause

|

Requirement

|

Comment, link

|

|

| 4 |

Context of the organization

|

|||

| 4.1 |

The organization and its context

|

|||

|

4.1

|

Determine external and internal issues | Understand everything that can influence the purpose and strategic direction of the company (corporate culture, innovation, strategic direction, competition, market, obligations). Cf. sub-clause 6.1 | ||

|

4.1

|

Identify, review and update information about external and internal issues | Issue: what can be gained or lost during an activity (factors, conditions). Some issues may change quickly, so stay alert. See § 9.3 | ||

|

3

|

4.1

|

Identify, review and update information about external and internal issues | Issue: what can be gained or lost during an activity (factors, conditions). Some issues may change quickly, so stay alert. See § 9.3 | |

| 4.2 |

Stakeholders

|

|

||

|

4

|

4.2 a | Determine stakeholders |

"There is only one valid definition of a business purpose: to create a customer. Peter Drucker". List of relevant stakeholders |

|

| 5 |

4.2 b

|

Clarify the requirements of the stakeholders | Every need and expectation is unique. Aim for a partnership in the long term. Including legal requirements | |

|

6

|

4.2

|

Identify, review and update information about stakeholders | Before accepting an order. Cf. sub-clause 7.5 | |

| 4.3 |

Scope of the FSMS

|

|

||

|

7

|

4.3

|

Determine the scope of the FSMS | Geographical and organizational scope available to stakeholders | |

|

8

|

4.3

|

Take into account the products and services | Including specific processes and production sites | |

|

9

|

4.3

|

Take into account everything that can have an influence on the food safety of end products | Such as activities, products and services | |

|

10

|

4.3 a

|

Take into account the external and internal issues | Cf. sub-clause 4.1 | |

| 11 |

4.3 b

|

Take into account the requirements of the stakeholders | Cf. sub-clause 4.2 | |

| 12 | 4.3 | Maintain the scope of the FSMS available as documented information | Cf. sub-clause 7.5 | |

| 4.4 |

FSMS

|

|||

|

13

|

4.4

|

Establish, implement, maintain, update and continually improve a process-based FSMS | For this it is necessary to determine the necessary processes, their applications, sequence and interactions. Process sheet, flow diagram | |

| 5 |

Leadership

|

|||

| 5.1 |

Commitment

|

|

||

|

14

|

5.1 a

|

Ensure that the food safety policy and objectives are established and are compatible with the strategic direction of the organization | "When you sweep the stairs, you start at the top". Romanian proverb. Top management demonstrates leadership (fully assuming its responsibility and commitment) | |

| 15 | 5.1 b | Integrate the FSMS requirements into the internal business processes | Cf. sub-clause 4.4 | |

|

16

|

5.1 c

|

Provide the resources neede for the FSMS | Cf. sub-clause 7.1 | |

|

17

|

5.1 d

|

Communicate the importance of an effective and conforming FSMS | Cf. sub-clause 7.4 | |

|

18

|

5.1 e

|

Evaluate and maintain the FSMS | In order to achieve its intended results , cf. sub-clause 4.1 | |

|

19

|

5.1 f

|

Support persons contributing to the FSMS | In order to improve the effectiveness of the FSMS. "Employee first, customers second. Vineet Nayar". | |

|

20

|

5.1 g

|

Promote continual improvement | Essential commitment of top management | |

|

21

|

5.1 h

|

Support management leadership |

The responsibility and authority of managers are supported at all times by top management |

|

| 5.2 |

FS policy

|

|

||

| 5.2.1 |

Establishing the FS policy

|

|

||

| 22 | 5.2.1 a | Establish, implement and maintain an appropriate food safety policy | Top management applies a policy tailored to the purpose, strategic direction, culture and context of the organization | |

| 23 | 5.2.1 b | Provide a framework | In order to define and review the food safety objectives | |

| 24 | 5.2.1 c | Include a commitment to satisfy FS requirements | Requirements relating to he food safety, statutory, regulatory and customer | |

| 25 | 5.2.1 d | Include communication | Internally and externally, cf. sub-clause 7.4 | |

| 26 | 5.2.1 e | Include a commitment to continual improvement | Of the FSMS | |

| 27 | 5.2.1 f | Include the competence guarantee | In food safety | |

| 5.2.2 |

Communicating the FS policy

|

|||

| 28 | 5.2.2 a | Maintain the FS policy as documented information | And available internally, cf. sub-clause 7.5 | |

| 29 | 5.2.2 b | Communicate the FS policy | In order to be understood ans implemented, cf. sub-clause 7.4 | |

| 30 | 5.2.2 c | Keep the FS policy available to stakeholders | The FS policy cannot be a confidential document, it is available to relevant stakeholders | |

|

5.3

|

Roles, responsibilities, authorities

|

|

||

|

31

|

5.3.1

|

Define and communicate responsibilities and authorities | Top management assigns all relevant roles of the FSMS | |

|

32

|

5.3.1 a

|

Assign the responsibilities and authorities | In order to ensure that the FSMS conforms to the requirements of ISO 22000 | |

|

33

|

5.3.1 b

|

Assign the responsibilities and authorities | In order to report on the performance of the FSMS to top management | |

|

34

|

5.3.1 c

|

Assign the responsibilities and authorities | In order to appoint the food safety team leader and its members | |

|

35

|

5.3.1 d

|

Assign the responsibilities and authorities | In order to designate persons who can initiate and document actions | |

|

36

|

5.3.2 a

|

Ensure that the FSMS is established, implemented, maintained and updated | Role of the FS team leader | |

|

37

|

5.3.2 b

|

Manage and organize the FS team | Role of the FS team leader | |

|

38

|

5.3.2 c

|

Ensure the training and competencies of the FS team | Role of the FS team leader, cf. sub-clause 7.2 | |

|

39

|

5.3.2 d

|

Report to top management on the suitability of the FSMS | Role of the FS team leader | |

|

40

|

5.3.3

|

Have the responsibility to report to identified persons | For any FSMS problem, by all staff | |

|

6

|

Planning

|

|||

| 6.1 |

Actions to address risks

|

|||

| 41 | 6.1.1 a | Determine risks and opportunities | In order to ensure that the FSMS can achieve its intended results, cf. sub-clauses 4.1 (context) and 4.2 (stakeholders) and 4.3 (scope). "Any decision involves a risk". Peter Barge | |

| 42 | 6.1.1 b | Determine risks and opportunities | In order to increase desirable affects (beneficial impact - opportunity) | |

|

43

|

6.1.1 c

|

Determine risks and opportunities | In order to reduce undesired effects (negative effect - threat). Risks related to public health are the responsibility of public authorities | |

|

44

|

6.1.1 d

|

Determine risks and opportunities | In order to confirm the continual improvement approach, cf. sub-clause 10.2 | |

|

45

|

6.1.2 a

|

Plan actions to address risks and opportunities | Take into account risks in each process | |

|

46

|

6.1.2.b 1

|

Plan how to implement the actions | Define how to integrate actions into the FSMS, cf. sub-clause 4.4 | |

|

47

|

6.1.2 b 2

|

Plan how to evaluate the effectiveness of actions | Monitor the effectiveness of each action, cf. sub-clauses 9.1 and 9.2 | |

|

48

|

6.1.3 a

|

Adapt actions to address risks and opportunities | In relation to the potential impact on food safety product conformity | |

|

49

|

6.1.3 b

|

Adapt actions to address risks and opportunities | In relation to the conformity of food products and services with customers | |

|

50

|

6.1.3 c

|

Adapt actions to address risks and opportunities | In relation to requirements of the stakeholders | |

| 6.2 |

FS objectives

|

|

||

|

51

|

6.2.1

|

Establish objectives for the FSMS | "He who has no goals will not achieve them. Sun Tzu", cf. sub-clause 7.5 | |

|

52

|

6.2.1 a

|

Choose objectives for the FSMS | Clarify the criteria for setting objectives consistent with the FS policy | |

|

53

|

6.2.1 b

|

Use measurable objectives | And realistic | |

|

54

|

6.2.1 c

|

Take into account applicable FS requirements | Including statutory, regulatory and customer | |

|

55

|

6.2.1 d

|

Monitor objectives | And verify them regularly | |

|

56

|

6.2.1 e

|

Communicate on objectives | At all levels | |

|

57

|

6.2.1 f

|

Update objectives | During management review, cf. sub-clause 9.3 | |

| 58 | 6.2.1 | Retain documented information on the objectives of the FSMS | Cf. sub-clause 7.5 | |

| 59 | 6.2.2 a | Plan what will be done | In order to achieve FS objectives | |

| 60 |

6.2.2 b

|

Plan the resources needed | In order to achieve FS objectives | |

| 61 |

6.2.2 c

|

Plan the responsibilities | In order to achieve FS objectives | |

| 62 |

6.2.2 d

|

Plan the deadlines to respect | In order to achieve FS objectives | |

| 63 |

6.2.2 e

|

Plan how the results will be evaluated | In order to achieve FS objectives | |

| 6.3 |

Changes

|

|||

| 64 |

6.3

|

Plan the need for changes to the FSMS, implementation and communication | "The only person who likes change is a wet baby" | |

| 65 |

6.3 a

|

Plan the changes | Taking into account the purpose of the change and potential consequences, cf. sub-clause 6.1 | |

| 66 |

6.3 b

|

Plan the changes | Taking into account the continued integrity of the FSMS | |

|

67

|

6.3 c | Plan the changes | Taking into account the resources available, cf. sub-clause 7.1 | |

|

68

|

6.3 d | Plan the changes | Taking into account the responsibilities and authorities allocated, cf. sub-clause 5.3 | |

| 7 |

Support

|

|||

| 7.1 |

Resources

|

|

||

| 7.1.1 |

General

|

|

||

|

69

|

7.1.1 | Provide the resources needed | In order to support the FSMS, cf. sub-clauses 7.1 and 10.3 | |

|

70

|

7.1.1 a | Take into account the existing resources | And their capabilities and constraints, cf. sub-clause 7.1.2 | |

|

71

|

7.1.1 b | Take into account the need for external providers | In order to obtain the necessary services not available internally | |

| 7.1.2 |

People

|

|

||

|

72

|

7.1.2 | Provide competent persons necessary to operate and maintain an effective FSMS | "But in the long run - and I emphasis this - no matter how good or successful you are or how clever or crafty, your business and its future are in the hands of the people you hire." Akio Morita " | |

|

73

|

7.1.2 | Retain the contract with external experts as documented information | Including their competence, responsibilities and authorities, cf. sub-clause 7.5 | |

| 7.1.3 |

Infrastructure

|

|

||

|

74

|

7.1.3 | Provide and maintain the infrastructure needed to run processes | In order to obtain compliant products and services. Examples: buildings, equipment, transportation, computer hardware, software | |

| 7.1.4 |

Work environment

|

|

||

|

75

|

7.1.4 | Provide and maintain the work environment needed to run processes | In order to obtain compliant products and services. Examples: corporate culture, work environment, temperature, ergonomics | |

| 7.1.5 |

External elements of the FSMS

|

|||

|

76

|

7.1.5 a | Ensure that externally provided elements of the FSMS are developed in accordance with the requirements of ISO 22000 | Like PRPs, the hazard analysis and the hazard control plan, cf. sub-clauses 8.2, 8.5.2 and 8.5.4 | |

|

77

|

7.1.5 b | Ensure that externally provided elements of the FSMS are applicable to the sites of the organization | Including processes and products | |

|

78

|

7.1.5 c | Ensure that externally provided elements of the FSMS are adapted to the processes and products of the organization | By the food safety team | |

|

79

|

7.1.5 d | Ensure that externally provided elements of the FSMS are implemented, maintained and updated in accordance with the requirements of ISO 22000 | Cf. sub-clauses 8.1 to 8.9 | |

|

80

|

7.1.5 e | Ensure that externally provided elements of the FSMS are retained as documented information | Cf. sub-clause 7.5 | |

| 7.1.6 |

External providers

|

|

||

|

81

|

7.1.6 a | Establish and apply criteria for the evaluation and selection of external providers and monitor their performance | In order to control processes, products and services provided. "You can outsource the activity but you can’t outsource the risk. Michael Gallagher " | |

|

82

|

7.1.6 b | Communicate requirements to external providers | Cf. sub-clause 7.4 | |

|

83

|

7.1.6 c | Ensure that what is provided by external providers does not adversely affect the organization to meet the requirements of the FSMS | Processes, products and services provided are under control | |

|

84

|

7.1.6 d | Retain documented information on evaluation of external providers | Cf. sub-clause 7.5 | |

| 7.2 |

Competence

|

|||

| 85 | 7.2 a | Determine the necessary competence | Identify all the people who influence the performance of the FSMS | |

| 86 | 7.2 b | Ensure the persons responsible for the operation of the hazard control plan are competent | On the basis of appropriate training and experience | |

| 87 | 7.2 c | Ensure that the food safety team has multi-disciplinary competence | In relation to the development and application of the FSMS as processes, products, equipment and hazards | |

| 88 | 7.2 d | Acquire the necessary competence | And evaluate the effectiveness of actions undertaken | |

| 89 | 7.2 e | Retain documented information on competence | Cf. sub-clause 7.5 | |

| 7.3 | Awareness |

|

||

| 90 | 7.3 a | Make all relevant persons aware of the FS policy | Including people working under the organization's control. Cf. sub-clause 5.2 | |

| 91 | 7.3 b | Make all relevant persons aware of the FS objectives | Cf. sub-clause 6.2 | |

| 92 | 7.3 c | Make all relevant persons aware of their contribution | And on the beneficial effects of improving the performance of the FSMS | |

| 93 | 7.3 d | Make all relevant persons aware to the negative impacts | If not conforming with FSMS requirements, cf. sub-clauses 8.9 and 10.1 | |

| 7.4 |

Communication

|

|||

| 7.4.1 |

General

|

|

||

| 94 | 7.4.1 a | Determine the necessary internal and external communication relevant to the FSMS | On which subjects to communicate. "Good news walks, bad news runs". Swedish proverb | |

| 95 | 7.4.1 b | Determine the necessary internal and external communication relevant to the FSMS | When to communicate | |

| 96 | 7.4.1 c | Determine the necessary internal and external communication relevant to the FSMS | With whom to communicate | |

| 97 | 7.4.1 d | Determine the necessary internal and external communication relevant to the FSMS | How to communicate | |

| 98 | 7.4.1 e | Determine the necessary internal and external communication relevant to the FSMS | Who will communicate | |

| 99 | 7.4.1 | Ensure that the requirement for effective communication is understood | By all persons whose activities have an impact on food safety | |

| 7.4.2 |

External communication

|

|||

| 100 | 7.4.2 | Communicate externally sufficient information | Available to stakeholders | |

| 101 | 7.4.2 a | Communicate effectively with external providers | Cf. sub-clause 7.1.6 | |

| 102 | 7.4.2 b 1 | Communicate effectively with customers and consumers | Product information related to food safety | |

| 103 | 7.4.2 b 2 | Communicate effectively with customers and consumers | On food hazards requiring control by other companies in the food chain | |

| 104 | 7.4.2 b 3 | Communicate effectively with customers and consumers | On contractual arrangements, inquiries, orders and amendments | |

| 105 | 7.4.2 b 4 | Communicate effectively with customers and consumers | On customer feedback and complaints | |

|

106

|

7.4.2 c

|

Communicate effectively with statutory authorities | And regulatory | |

|

107

|

7.4.2 d

|

Communicate effectively with other organizations | Regarding the FSMS | |

|

108

|

7.4.2

|

Designate people with responsibility and authority for external communication | For any information concerning food safety | |

|

109

|

7.4.2

|

Include information obtained as input for management review and update of the FSMS | Cf. sub-clauses 9.3, 4.4 and 10.3 | |

|

110

|

7.4.2

|

Retain documented information as evidence of external communication | Cf. sub-clause 7.5 | |

| 7.4.3 |

Internal communication

|

|

||

|

111

|

7.4.3

|

Communicate on food safety | Internally | |

|

112

|

7.4.3 a

|

Ensure that the food safety team is informed of changes | Regarding products | |

|

113

|

7.4.3 b

|

Ensure that the food safety team is informed of changes | Regarding raw materials, ingredients and services | |

|

114

|

7.4.3 c

|

Ensure that the food safety team is informed of changes | Regarding equipment and systems | |

|

115

|

7.4.3 d

|

Ensure that the food safety team is informed of changes | Regarding premises, location of equipment and environment | |

|

116

|

7.4.3 e

|

Ensure that the food safety team is informed of changes | regarding cleaning and sanitation | |

|

117

|

7.4.3 f

|

Ensure that the food safety team is informed of changes | Regarding packaging, storage and distribution | |

|

118

|

7.4.3 g

|

Ensure that the food safety team is informed of changes | Regarding competence, responsibilities and authorities | |

|

119

|

7.4.3 h

|

Ensure that the food safety team is informed of changes | Regarding statutory and regulatory requirements | |

|

120

|

7.4.3 i

|

Ensure that the food safety team is informed of changes | Regarding food safety hazards and control measures | |

|

121

|

7.4.3 j

|

Ensure that the food safety team is informed of changes | Regarding customer requirements | |

|

122

|

7.4.3 k

|

Ensure that the food safety team is informed of changes | Regarding information requests from stakeholders | |

|

123

|

7.4.3 l

|

Ensure that the food safety team is informed of changes | Regarding complaints and alerts on food safety hazards with the end product | |

|

124

|

7.4.3 m

|

Ensure that the food safety team is informed of changes | Regarding other conditions that have an impact on food safety | |

|

125

|

7.4.3

|

Include this information when updating the FSMS | Cf. sub-clauses 4.4 and 10.3 | |

|

126

|

Include this information to the management review | As input, cf. sub-clause 9.3 | ||

| 7.5 |

Documented information

|

|||

| 7.5.1 |

General

|

|||

| 127 | 7.5.1 a | Include documented information required by the ISO 22000 standard | Documented procedures (documented information to maintain):

|

|

| 128 | 7.5.1 b | Include documented information deemed necessary to the effectiveness of the FSMS | "Spoken words fly away, written ones stay. Latin proverb" | |

| 129 | 7.5.1 c | Include documented information and food safety requirements | Required by statutory, regulatory authorities and customers | |

| 7.5.2 |

Creating and updating

|

|||

| 130 | 7.5.2 a | Identify and describe documented information appropriately | Such as title, author, date, coding | |

| 131 | 7.5.2 b | Ensure that the format and the media of documented information are appropriate | Language, software and graphics version. Examples of media: paper, electronic | |

| 132 | 7.5.2 c | Review and approve documented information appropriately | Who writes, who codify, who approves | |

| 7.5.3 |

Control of documented information

|

|||

| 133 | 7.5.3.1 a | Control the availability of documented information | Where and when it is needed in a form suitable for use | |

| 134 | 7.5.3.1 b | Control the adequate protection of documented information | Such as loss of confidentiality, improper use or loss of integrity | |

| 135 | 7.5.3.2 a | Control the distribution, access and use of documented information | Who is responsible, methods to use, rules to respect | |

| 136 | 7.5.3.2 b | Control the distribution, access, retrieval and use of documented information | Including preservation, protection and readability | |

| 137 | 7.5.3.2 c | Control the changes of documented information | Using updated versions, restricted access of outdated versions | |

| 138 | 7.5.3.2 d | Control the retention and disposition of documented information | Retention and disposition | |

| 139 | 7.5.3.2 | Identify and control documented information of external origin | Unique codification, access, protection | |

| 140 | 7.5.3.2 | Protect documented information retained as evidence of conformity | Who has the right to read, who has the right to modify or eliminate | |

| 8 |

Realization of safe products

|

Do | ||

| 8.1 |

Operational planning and control

|

|||

| 141 | 8.1 a | Plan and determine the requirements for the realization of safe products | By establishing process criteria in order to control processes, cf. sub-clauses 4.4 and 6.1 | |

| 142 | 8.1 b | Control processes | In accordance with criteria | |

| 143 | 8.1 c | Keep documented information on process control | In order to ensure that the processes have been carried out as planned. Cf. sub-clause 7.5.1 | |

| 144 | 8.1 | Control planned and unintended changes | By analyzing the consequences of unintended changes, action to mitigate any adverse effects | |

| 145 | 8.1 | Control outsourced processes | Cf. sub-clause 7.1.6 | |

| 8.2 |

Prerequisite programs (PRPs)

|

|||

| 146 | 8.2.1 | Control PRPs in the products, product processing and work environment | In order to facilitate the prevention of contaminants | |

| 147 | 8.2.2 a | Adapt PRPs to the organization | And the context of the organization, cf. sub-clause 4.1 | |

| 148 | 8.2.2 b | Adapt PRPs to the type of operation | And the nature of the products | |

| 149 | 8.2.2 c | Apply the production system at all levels | Programs applicable in general or to a particular product or process | |

| 150 | 8.2.2 d | Approve PRPs | By the food safety team | |

| 151 | 8.2.3 | Identify statutory, regulatory and customer requirements | When selecting or establishing PRPs | |

| 152 | 8.2.3 a | Consider ISO/TS 22002 series | Only applicable part | |

| 153 | 8.2.3 b | Consider standards, codes of practice and guidelines | Such as NF V01-001 and NF V01-006, European regulations 178/2002, 852/2002, 183/2005 | |

| 154 | 8.2.4 a | Consider, when establishing PRPs | Buildings and utilities | |

| 155 | 8.2.4 b | Consider, when establishing PRPs | Premises, workplaces and facilities | |

| 156 | 8.2.4 c | Consider, when establishing PRPs | Supplies of air, water, energy and utilities | |

| 157 | 8.2.4 d | Consider, when establishing PRPs | Pest control, waste and sewage disposal | |

| 158 |

8.2.4 e

|

Consider, when establishing PRPs | Equipment and its accessibility for cleaning and maintenance | |

| 159 |

8.2.4 f

|

Consider, when establishing PRPs | Monitoring of external providers | |

| 160 | 8.2.4 g | Consider, when establishing PRPs | Reception of incoming materials, storage, handling, expedition and transport | |

| 161 | 8.2.4 h | Consider, when establishing PRPs | Prevention measures of cross contamination | |

| 162 | 8.2.4 i | Consider, when establishing PRPs | Cleaning and disinfecting | |

| 163 | 8.2.4 j | Consider, when establishing PRPs | Personal hygiene | |

| 164 | 8.2.4 k | Consider, when establishing PRPs | Product information | |

| 165 | 8.2.4 l | Consider, when establishing PRPs | Other elements needed | |

| 166 | 8.2.4 | Control documented information on PRPs | Including selection, establishment, monitoring and verification, cf. sub-clause 7.5 | |

| 8.3 |

Traceability

|

|||

| 167 | 8.3 | Be able to identify external providers | Including suppliers and distributors | |

| 168 | 8.3 a | Consider | Relation of materials, ingredients, intermediate products to the end products | |

| 169 | 8.3 b | Consider | Reworking and recycling | |

| 170 | 8.3 c | Consider | Distribution of the end product | |

| 171 | 8.3 | Identify statutory, regulatory and customer requirements | In relation with traceability | |

| 172 | 8.3 | Retain documented information as evidence of the traceability | For a defined period, as a minimum the shelf life of the product, cf. sub-clause 7.5 | |

| 173 | 8.3 | Verify and test the traceability system | And its effectiveness | |

| 8.4 |

Emergencies

|

|||

| 8.4.1 |

General

|

|||

| 174 | 8.4.1 | Prepare for and respond to emergencies | Procedures are in place to respond to everything that can have an impact on food safety | |

| 175 | 8.4.1 | Maintain documented information on emergencies and incidents | Cf. sub-clause 7.5 | |

| 8.4.2 |

Handling of emergencies

|

|||

| 176 | 8.4.2 a 1 | Respond to emergency situations and incidents | By identifying statutory and regulatory requirements | |

| 177 | 8.4.2 a 2 | Respond to emergency situations and incidents | By communicating internally appropriate information | |

| 178 | 8.4.2 a 3 | Respond to emergency situations and incidents | By communicationg externally appropriate information to stakeholders (customers, suppliers, authorities, media) | |

| 179 | 8.4.2 b | Take appropriate actions to reduce the consequences | Actions appropriate to the magnitude of the situation and the food safety impact such as natural disasters, interruption of services such as water, electricity | |

| 180 | 8.4.2 c | Simulate test procedures to emergency situations | Periodically, where practical | |

| 181 | 8.4.2 d | Update the documented information | On any emergency situation or incident occurred and realized simulations | |

| 8.5 |

Hazard control

|

|||

| 8.5.1 |

Preliminary steps

|

|||

| 8.5.1.1 |

General

|

|||

| 182 | 8.5.1.1 | Collect, maintain and update preliminary documented information | In order to analyze hazards. Done by the food safety team, cf. sub-clause 7.5 | |

| 183 | 8.5.1.1 a | Include statutory, regulatory and customer requirements | Cf. sub-clause 4.2 | |

| 184 | 8.5.1.1 b | Include products, processes and equipment | Provided by the organization | |

| 185 | 8.5.1.1 c | Include food safety hazards | Relevant to the FSMS | |

| 8.5.1.2 |

Characteristics of materials

|

|||

| 186 | 8.5.1.2 | Identify statutory and regulatory food safety requirements | For all raw materials, ingredients and product contact materials | |

| 187 | 8.5.1.2 a | Maintain documented information on components in contact with the product | Such as biological, chemical and physical characteristics, cf. sub-clauses 7.5 and 8.5.2 | |

| 188 | 8.5.1.2 b | Maintain documented information on components in contact with the product | Such as ingredients, additives and processing aids, cf. sub-clauses 7.5 and 8.5.2 | |

| 189 | 8.5.1.2 c | Maintain documented information on components in contact with the product | Such as animal, mineral or vegetable source, cf. sub-clauses 7.5 and 8.5.2 | |

| 190 | 8.5.1.2 d | Maintain documented information on components in contact with the product | Such as place of origin, cf. sub-clauses 7.5 and 8.5.2 | |

| 191 | 8.5.1.2 e | Maintain documented information on components in contact with the product | Such as production method, cf. sub-clauses 7.5 and 8.5.2 | |

| 192 | 8.5.1.2 f | Maintain documented information on components in contact with the product | Such as method of packaging and delivery, cf. sub-clauses 7.5 and 8.5.2 | |

| 193 | 8.5.1.2 g | Maintain documented information on components in contact with the product | Such as storage conditions and shelf life, cf. sub-clauses 7.5 and 8.5.2 | |

| 194 | 8.5.1.2 h | Maintain documented information on components in contact with the product | Such as preparation, handling or processing, cf. sub-clauses 7.5 and 8.5.2 | |

| 195 | 8.5.1.2 i | Maintain documented information on components in contact with the product | Such as food safety acceptance criteria or purchase specifications, cf. sub-clauses 7.5 and 8.5.2 | |

| 8.5.1.3 |

Characteristics of end products

|

|||

| 196 | 8.5.1.3 | Identify all statutory and regulatory food safety requirements | For all the end products | |

| 197 | 8.5.1.3 a | Maintain documented information concerning the characteristics of end products | Such as product name, cf. sub-clauses 7.5 and 8.5.2 | |

| 198 | 8.5.1.3 b | Maintain documented information concerning the characteristics of end products | Such as composition, cf. sub-clauses 7.5 and 8.5.2 | |

| 199 | 8.5.1.3 c | Maintain documented information concerning the characteristics of end products | Such as biological, chemical and physical characteristics, cf. sub-clauses 7.5 and 8.5.2 | |

| 200 | 8.5.1.3 d | Maintain documented information concerning the characteristics of end products | Such as shelf life and storage conditions, cf. sub-clauses 7.5 and 8.5.2 | |

| 201 | 8.5.1.3 e | Maintain documented information concerning the characteristics of end products | Such as packaging, cf. sub-clauses 7.5 and 8.5.2 | |

| 202 | 8.5.1.3 f | Maintain documented information concerning the characteristics of end products | Such as labeling, and handling, preparation and use instructions, cf. sub-clauses 7.5 and 8.5.2 | |

| 203 | 8.5.1.3 g | Maintain documented information concerning the characteristics of end products | Such as distribution and delivery methods, cf. sub-clauses 7.5 and 8.5.2 | |

| 8.5.1.4 |

Intended use

|

|||

| 204 | 8.5.1.4 | Consider the intended use and handling of the end product | Including reasonably expected unintended use and misuse | |

| 205 | 8.5.1.4 | Maintain the intended use as documented information | For the hazard analysis, cf. sub-clauses 7.5 and 8.5.2 | |

| 206 | 8.5.1.4 | Identify groups of consumers or users | Where appropriate | |

| 207 | 8.5.1.4 | Identify groups of consumers or users known to be especially vulnerable | To specific food safety hazards | |

| 8.5.1.5 |

Flow diagrams and description of processes

|

|||

| 8.5.1.5.1 |

Preparation of the flow diagrams

|

|||

| 208 | 8.5.1.5.1 | Establish, maintain and update flow diagrams for the processes, products and product categories | To be done by the food safety team as documented information, cf. sub-clause 7.5 | |

| 209 | 8.5.1.5.1 | Use flow diagrams as a graphic representation of processes | In order to evaluate food safety hazards during hazard analysis , cf. sub-clause 8.5.2 | |

| 210 | 8.5.1.5.1 | Create clear, accurate and detailed flow diagrams | In order to carry out a hazard analysis , cf. sub-clause 8.5.2 | |

| 211 | 8.5.1.5.1 a | Include in the flow diagram | Steps, sequences and interactions | |

| 212 | 8.5.1.5.1 b | Include in the flow diagram | Any outsourced processes, cf. sub-clause 7.1.6 |

|

| 213 | 8.5.1.5.1 c | Include in the flow diagram | Components introduction points (raw materials, ingredients, processing aids, packaging, intermediate products) | |

| 214 | 8.5.1.5.1 d | Include in the flow diagram | Points of reworking and recycling | |

| 215 | 8.5.1.5.1 e | Include in the flow diagram | Points of release of end products, intermediate products, derivatives and waste | |

| 8.5.1.5.2 |

On-site confirmation of flow diagrams

|

|||

| 216 | 8.5.1.5.2 | Confirm on-site the accuracy of the flow diagrams | To be done by the food safety team | |

| 217 | 8.5.1.5.2 | Update the flow diagrams | To be done by the food safety team | |

| 218 | 8.5.1.5.2 | Retain flow diagrams as documented information | Cf. sub-clause 7.5 | |

| 8.5.1.5.3 |

Description of processes and their environment

|

|||

| 219 | 8.5.1.5.3 a | Describe the layout of promises | To be done by the food safety team in order to carry out an analysis of hazards, including in handling areas | |

| 220 | 8.5.1.5.3 b | Describe processing equipment, contact materials, processing aids and flow of materials | And material flow | |

| 221 | 8.5.1.5.3 c | Describe existing PRPs, process parameters and control measures | And procedures that can influence food safety | |

| 222 | 8.5.1.5.3 d | Describe external requirements that can impact the control measures | Such as statutory, regulatory and customers | |

| 223 | 8.5.1.5.3 | Include the variations | Resulting from expected seasonal changes or shift patterns | |

| 224 | 8.5.1.5.3 | Update and maintain the descriptions of processes as documented information | Cf. sub-clause 7.5 | |

| 8.5.2 |

Hazard control

|

|||

| 8.5.2.1 |

General

|

|||

| 225 | 8.5.2.1 | Conduct a hazard analysis based on the preliminary information | To be done by the food safety tean in order to determine hazards to be controlled, cf. sub-clause 8.5.1.1 | |

| 226 | 8.5.2.1 | Ensure food safety | With a sufficient degree of control. Or, where appropriate, use a combination of control measures | |

| 8.5.2.2 |

Hazard identification and acceptable levels

|

|||

| 227 | 8.5.2.2.1 | Identify and document all food safety hazard | In relation to the process, product and the environment of the process. Examine the hazards in sufficient detail to evaluate them and select the appropriate control measures | |

| 228 | 8.5.2.2.1 a | Base hazard identification on | The preliminary information, cf. sub-clause 8.5.1.1 | |

| 229 | 8.5.2.2.1 b | Base hazard identification on | The experience of the FS team, staff and external experts | |

| 230 | 8.5.2.2.1 c | Base hazard identification on | Internal and external information (epidemiological and scientific data) | |

| 231 | 8.5.2.2.1 d | Base hazard identification on | The information of the food chain (food safety-related hazards of end products, intermediate products and at the moment of consumption) | |

| 232 | 8.5.2.2.1 e | Base hazard identification on | Statutory, regulatory and customer requirements and the Codex Alimentarius Commission | |

| 233 | 8.5.2.2.2 | Identify the possible steps at which each hazard can be introduced | Such as reception, processing, handling, storage, distribution, delivery | |

| 234 | 8.5.2.2.2 a | Consider when identifying hazards | Stages preceding and following in the food chain | |

| 235 | 8.5.2.2.2 b | Consider when identifying hazards | All steps in the flow diagram | |

| 236 | 8.5.2.2.2 c | Consider when identifying hazards | People, equipment, services and process environment | |

| 237 | 8.5.2.2.3 | Determine the acceptable level of each food safety hazard identified | In the end product | |

| 238 | 8.5.2.2.3 a | Identify statutory, regulatory and customer requirements | When determining acceptable levels | |

| 239 | 8.5.2.2.3 b | Consider the intended use | When determining acceptable levels | |

| 240 | 8.5.2.2.3 c | Consider any other relevant information | When determining acceptable levels | |

| 241 | 8.5.2.2.3 | Maintain documented information on acceptable levels | And the justification for the acceptable levels, cf. sub-clause 7.5 | |

| 8.5.2.3 |

Hazard assessment

|

|||

| 242 | 8.5.2.3 | Conduct a hazard assessment for each identified hazard | In order to determine the need for prevention or reduction | |

| 243 | 8.5.2.3 a | Evaluate each food safety hazard | With regard to the likelihood of its occurrence prior to the application of control measures | |

| 244 | 8.5.2.3 b | Evaluate each food safety hazard | With regard to the severity of its adverse health effects in relation to the intended use, cf. 8.5.1.4 | |

| 245 | 8.5.2.3 | Identify any significant hazards | In relation to food safety | |

| 246 | 8.5.2.3 | Describe the methodology used and maintain the results of the hazard assessment as documented information | Cf. sub-clause 7.5 | |

| 8.5.2.4 |

Control measures

|

|

||

| 247 | 8.5.2.4.1 | Select a control measure or combination of control measures based on the hazard assessment | In order to prevent or reduce significant food safety hazards to an acceptable level, cf. sub-clause 8.5.2.3 | |

| 248 | 8.5.2.4.1 | Categorize the control measures in oPRP or CCP | Cf. sub-clause 8.5.4 | |

| 249 | 8.5.2.4.1 | Carry out the categorization of control measures | Using a systematic approach | |

| 250 | 8.5.2.4.1 a | Assess for each control measure selected | The likelihood of failure of its functioning | |

| 251 | 8.5.2.4.1 b 1 | Assess for each control measure selected | The severity of the consequences of failure including the impact on significant food safety hazards | |

| 252 | 8.5.2.4.1 b 2 | Assess for each control measure selected | The severity of the consequences of failure including the location in relation to other control measures | |

| 253 | 8.5.2.4.1 b 3 | Assess for each control measure selected | The severity of the consequences of failure including whether the measure will reduce the hazards to an acceptable level | |

| 254 | 8.5.2.4.1 b 4 | Assess for each control measure selected | The severity of the consequences of failure including whether it is a single measure or is part of combination of control measures | |

| 255 | 8.5.2.4.2 a | Include an assessment of the feasibility for each control measure | Establishing measurable critical limits and measurable action criteria (observable) | |

| 256 | 8.5.2.4.2 b | Include an assessment of the feasibility for each control measure | Monitoring to detect any failure to remain within critical limits or measurable action criteria | |

| 257 | 8.5.2.4.2 c | Include an assessment of the feasibility for each control measure | Applying timely corrections | |

| 258 | 8.5.2.4.2 | Maintain the decision-making process, results of the selection and categorization of the control measures as documented information | Cf. sub-clause 7.5 | |

| 259 | 8.5.2.4.2 | Maintain external requirements as documented information | Requirements such as statutory, regulatory and customer, that can impact the selection and strictness of the control measures, cf. sub-clause 7.5 | |

| 8.5.3 |

Validation of control measures and their combinations

|

|||

| 260 | 8.5.3 | Validate the selected control measures that are capable of achieving the intended control of significant food safety hazards | By the food safety team | |

| 261 | 8.5.3 | Conduct validation prior to implementation of control measure or combination of control measures | Including validation in the hazard control plan, cf. sub-clause 8.5.4 and following any change of the plan, cf. sub-clauses 7.4.2, 7.4.3, 10.2 and 10.3 | |

| 262 | 8.5.3 | Re-assess the control measures when the result of validation shows that the control measures are not capable of achieving the intended control | By the food safety team | |

| 263 | 8.5.3 | Maintain the validation methodology and evidence of capability of the control measures to achieve the intended control as documented information | By the food safety team, cf. sub-clause 7.5 | |

| 8.5.4 |

Hazard control plan (HACCP/oPRP plan

|

|||

| 8.5.4.1 |

General

|

|||

| 264 | 8.5.4.1 | Establish, implement and maintain a hazard control plan | By the food safety team | |

| 265 | 8.5.4.1 | Maintain the hazard control plan as documented information | Cf. sub-clause 7.5 | |

| 266 | 8.5.4.1 a | Include in the hazard control plan | The food safety hazards have to be controlled at the CCP level or through oPRP | |

| 267 | 8.5.4.1 b | Include in the hazard control plan | Critical limits at CCP or action criteria for oPRP | |

| 268 | 8.5.4.1 c | Include in the hazard control plan | Monitoring procedures | |

| 269 | 8.5.4.1 d | Include in the hazard control plan | Corrections to undertake in case critical limits or action criteria are not met | |

| 270 | 8.5.4.1 e | Include in the hazard control plan | Responsibilities and authorities | |

| 271 | 8.5.4.1 f | Include in the hazard control plan | Records (documented information to retain) of monitoring, cf. sub-clause 7.5 | |

| 8.5.4.2 |

Critical limits and action criteria

|

|||

| 272 | 8.5.4.2 | Specify critical limits and action criteria | At CCPs and for oPRPs | |

| 273 | 8.5.4.2 | Maintain the rationale for their determination as documented information | Cf. sub-clause 7.5 | |

| 274 | 8.5.4.2 | Use measurable critical limits at CCPs | By the food safety team | |

| 275 | 8.5.4.2 | Ensure that the acceptable level is not exceeded | Conformance with critical limits | |

| 276 | 8.5.4.2 | Use measurable action criteria for oPRPs | Or observable | |

| 277 | 8.5.4.2 | Ensure that the acceptable level is not exceeded | Conformance with action criteria | |

| 8.5.4.3 |

Monitoring systems

|

|||

| 278 | 8.5.4.3 | Establish at each CCP a monitoring system for each control measure or combination of control measures | In order to detect any failure to remain within critical limits | |

| 279 | 8.5.4.3 | Include in the monitoring system all scheduled measurements | Relative to critical limits | |

| 280 | 8.5.4.3 | Establish for each oPRP a monitoring system for each control measure or combination of control measures | In order to detect any failure to remain within action criteria | |

| 281 | 8.5.4.3 a | Include in the monitoring system documented information | On results of measurements or observation within an adequate time frame, cf. sub-clause 7.5 | |

| 282 | 8.5.4.3 b | Include in the monitoring system documented information | On monitoring methods or devices used, cf. sub-clause 7.5 | |

| 283 | 8.5.4.3 c | Include in the monitoring system documented information | On calibration methods or equivalent methods, cf. sub-clause 7.5 | |

| 284 | 8.5.4.3 d | Include in the monitoring system documented information | On monitoring frequency, cf. sub-clause 7.5 | |

| 285 | 8.5.4.3 e | Include in the monitoring system documented information | On monitoring results, cf. sub-clause 7.5 | |

| 286 | 8.5.4.3 f | Include in the monitoring system documented information | On monitoring responsibilities and authorities | |

| 287 | 8.5.4.3 g | Include in the monitoring system documented information | On responsibilities and authorities related to evaluation of monitoring results | |

| 288 | 8.5.4.3 | Allow each CCP to quickly detect any failure to remain within critical limits | In order to isolate and evaluate the product, cf. sub-clause 8.9.4.1 | |

| 289 | 8.5.4.3 | Use monitoring method and frequency for each oPRP proportionate to the likelihood of failure | And the severity of consequences | |

| 290 | 8.5.4.3 | Support the monitoring method of an oPRP based on observation data as a visual inspection | By instructions or specifications | |

| 8.5.4.4 |

Actions when critical limits or action criteria are not met

|

|||

| 291 | 8.5.4.4 | Specify corrections and corrective actions to be taken when critical limits and action criteria are not met | Cf. sub-clauses 8.9.2 and 8.9.3 | |

| 292 | 8.5.4.4 a | Ensure that potentially unsafe products are not released | Cf. sub-clause 8.9.4.1 | |

| 293 | 8.5.4.4 b | Identify the cause of nonconformity | Cf. sub-clause 8.9.3 | |

| 294 | 8.5.4.4 c | Ensure that again the critical limits and action criteria are met | Cf. sub-clause 9.1 | |

| 295 | 8.5.4.4 d | Ensure that recurrence is prevented | Cf. sub-clause 8.9.3 | |

| 296 | 8.5.4.4 | Make corrections and corrective actions | In accordance with sub-clauses 8.9.2 and 8.9.3 | |

| 8.5.4.5 |

Implementation of the hazard control plan

|

|||

| 297 | 8.5.4.5 | Implement and maintain the hazard control plan | Cf. sub-clause 8.5.4.1 | |

| 298 | 8.5.4.5 | Retain evidence of the implementation of the hazard control plan as documented information | Cf. sub-clause 7.5 | |

| 8.6 |

Update of PRPs and the hazard control plan

|

|||

| 299 | 8.6 a | Update, if necessary, the information specifying the PRPs and the hazard control plan | Characteristics of product-contact materials, cf. sub-clause 8.5.1.2 | |

| 300 | 8.6 b | Update, if necessary, the information specifying the PRPs and the hazard control plan | Characteristics of end product, cf. sub-clause 8.5.1.3 | |

| 301 | 8.6 c | Update, if necessary, the information specifying the PRPs and the hazard control plan | Intended use, cf. sub-clause 8.5.1.4 | |

| 302 | 8.6 d | Update, if necessary, the information specifying the PRPs and the hazard control plan | Flow diagrams, descriptions of processes and process environment, cf. sub-clause 8.5.1.5.1 | |

| 303 | 8.6 | Ensure that the hazard control plan and the PRPs are updated | Cf. sub-clauses 8.5.4 and 8.2 | |

| 8.7 |

Control of monitoring and measuring

|

|||

| 304 | 8.7 | Provide evidence that the specified monitoring and measuring methods are adequate related to the PRPs and the hazard control plan | Equipment in use | |

| 305 | 8.7 a | Use appropriate monitoring and measuring equipment | Calibrated and verified regularly | |

| 306 | 8.7 b | Use appropriate monitoring and measuring equipment | Adjusted as many times as needed | |

| 307 | 8.7 c | Use appropriate monitoring and measuring equipment | Identified (with calibration date) | |

| 308 | 8.7 d | Use appropriate monitoring and measuring equipment | Protected against ill-fitting | |

| 309 | 8.7 e | Use appropriate monitoring and measuring equipment | Protected against deterioration | |

| 310 | 8.7 | Retain the results of calibration and verification as documented information | Cf. sub-clause 7.5 | |

| 311 | 8.7 | Base calibration on standards | National or international | |

| 312 | 8.7 | Retain the basis used for calibration or verification as documented information | When no standard exists, cf. sub-clause 7.5 | |

| 313 | 8.7 | Assess the validity of the previous results | When the equipment or the process environment is not conforming | |

| 314 | 8.7 | Take appropriate action | On nonconforming equipment or process environment | |

| 315 | 8.7 | Maintain the assessment and resulting action as documented information | Cf. sub-clause 7.5 | |

| 316 | 8.7 | Validate software used in monitoring and measuring prior to use | By the organization, the supplier or third party | |

| 317 | 8.7 | Maintain validation activities as documented information | Cf. sub-clause 7.5 | |

| 318 | 8.7 | Update the software in a timely manner | With the software supplier | |

| 319 | 8.7 | Authorize, document and validate software changes | Prior implementation | |

| 8.8 |

Verification of PRPs and hazard control plan

|

|||

| 8.8.1 |

Verification

|

|||

| 320 | 8.8.1 | Establish, implement and maintain verification activities | "Inspection does not improve quality, nor guarantee quality. Edwards Deming" | |

| 321 | 8.8.1 | Define purpose, methods, frequencies and responsibilities for the verification activities | This is part of verification planning | |

| 322 | 8.8.1 a | Include in verification activities | The implementation and effectiveness of PRPs | |

| 323 | 8.8.1 b | Include in verification activities | The implementation and effectiveness of the hazard control plan | |

| 324 | 8.8.1 c | Include in verification activities | The state of acceptable hazard levels | |

| 325 | 8.8.1 d | Include in verification activities | Updating input to the hazard analysis | |

| 326 | 8.8.1 e | Include in verification activities | The implementation and effectiveness of other actions | |

| 327 | 8.8.1 | Ensure that verification activities are not carried out by the person responsible for monitoring these activities | "No one is a judge in his own case. Latin proverb" | |

| 328 | 8.8.1 | Retain verification results as documented information | And communicate them, cf. sub-clauses 7.4 and 7.5 | |

| 329 | 8.8.1 | Handle products as potentially unsafe and apply corrective actions | When the verification found nonconforming samples (non-acceptable level of the food safety hazard), cf. sub-clauses 8.5.2.2, 8.9.4.3 and 8.9.3 | |

| 8.8.2 |

Analysis of verification activities

|

|||

| 330 | 8.8.2 | Conduct an analysis of the results of verification and use as an input to the performance evaluation of the FSMS | Cf. sub-clause 9.1.2 | |

| 8.9 |

Control of nonconformities

|

|||

| 8.9.1 |

General

|

|||

| 331 | 8.9.1 | Ensure that the results from the monitoring of oPRPs and at CCPs are evaluated by competent persons | And who has the authority to initiate corrections and corrective actions, cf. sub-clauses 8.9.2 and 8.9.3 | |

| 8.9.2 |

Corrections

|

|||

| 332 | 8.9.2.1 | Identify and control nonconforming products with corrections | When critical limits at CCPs or action criteria for oPRPs are not met | |

| 333 | 8.9.2.1 a | Include in established, maintained and updated documented information | A method of identification, assessment and correction for affected products in order to ensure their proper handling, cf. sub-clause 7.5 | |

| 334 | 8.9.2.1 b | Include in established, maintained and updated documented information | Arrangements for review of corrections | |

| 335 | 8.9.2.2 | Identify products when critical limits at CCP are not met | Considering them as unsafe products, cf. sub-clause 8.9.4.1 | |

| 336 | 8.9.2.3 a | Carry out actions where action criteria for an oPRP are not met | By determining the food safety consequences | |

| 337 | 8.9.2.3 b | Carry out actions where action criteria for an oPRP are not met | By determining the causes | |

| 338 | 8.9.2.3 c | Carry out actions where action criteria for an oPRP are not met | By identifying the products concerned and their handling, cf. sub-clause 8.9.4.1 | |

| 339 | 8.9.2.3 | Retain results of the evaluation as documented information | Cf. sub-clause 7.5 | |

| 340 | 8.9.2.4 a | Retain results of corrections as documented information | The nature of the nonconformity, cf. sub-clause 7.5 | |

| 341 | 8.9.2.4 b | Retain results of corrections as documented information | The causes of the nonconformity, cf. sub-clause 7.5 | |

| 342 | 8.9.2.4 c | Retain results of corrections as documented information | The consequences of the nonconformity, cf. sub-clause 7.5 | |

| 8.9.3 |

Corrective actions

|

|||

| 343 | 8.9.3 | Evaluate the need for corrective actions | When critical limits at CCPs or action criteria for oPRPs are not met | |

| 344 | 8.9.3 | Establish and maintain documented information on the control of nonconformities | In order to prevent recurrence of nonconformities, cf. sub-clause 7.5 | |

| 345 | 8.9.3 a | Include in corrective actions | Reviewing nonconformities following complaints or regulatory reports | |

| 346 | 8.9.3 b | Include in corrective actions | Reviewing trends in monitoring that can indicate loss of control | |

| 347 | 8.9.3 c | Include in corrective actions | Determining the root causes of nonconformities | |

| 348 | 8.9.3 d | Include in corrective actions | Determining and implementing actions in order to ensure that nonconformities will not recur | |

| 349 | 8.9.3 e | Include in corrective actions | Documenting the results, cf. sub-clause 7.5 | |

| 350 | 8.9.3 f | Include in corrective actions | Verifying the effectiveness of actions | |

| 351 | 8.9.3 | Retain documented information on corrective actions | Cf. sub-clause 7.5 | |

| 8.9.4 |

Handling of potentially unsafe products

|

|||

| 8.9.4.1 |

General

|

|||

| 352 | 8.9.4.1 a | Undertake actions to prevent the entry of potentially unsafe products into the food chain unless | Food safety hazards are reduced to acceptable levels | |

| 353 | 8.9.4.1 b | Undertake actions to prevent the entry of potentially unsafe products into the food chain unless | Food safety hazards will be reduced to acceptable levels prior to entering the food chain | |

| 354 | 8.9.4.1 c | Undertake actions to prevent the entry of potentially unsafe products into the food chain unless | The product still meets the defined acceptable level despite the nonconformity | |

| 355 | 8.9.4.1 | Retain the control of products that have been identified as potentially unsafe | Until the products are evaluated and their disposition determined, cf. sub-clause 8.9.4.3 | |

| 356 | 8.9.4.1 | Notify relevant stakeholders if products are subsequently determined to be unsafe | Initiate a withdrawal or recall, cf. sub-clause 8.9.5 | |

| 357 | 8.9.4.1 | Retain feedback from stakeholders and authorization for dealing with potentially unsafe products as documented information | Cf. sub-clause 7.5 | |

| 8.9.4.2 |

Evaluation for release

|

|||

| 358 | 8.9.4.2 | Evaluate each lot of products including nonconformities | Concerning all unsafe products | |

| 359 | 8.9.4.2 | Handle products with critical limits at CCPs not met | Do not release but handled in accordance with sub-clause 8.9.4.3 | |

| 360 | 8.9.4.2 a | Release products as safe but affected by failure to meet action criteria for oPRPs provided that | Monitoring demonstrates that the control measures are effective | |

| 361 | 8.9.4.2 b | Release products as safe but affected by failure to meet action criteria for oPRPs provided that | The combined effect of the control measures conforms to the performance intended (identified acceptable levels) | |

| 362 | 8.9.4.2 c | Release products as safe but affected by failure to meet action criteria for oPRPs provided that | The results of sampling, analysis or other verification activities demonstrate that the products conform to the identified acceptable levels | |

| 363 | 8.9.4.2 |

Retain evaluation for release of products as documented information |

Cf. sub-clause 7.5 | |

| 8.9.4.3 |

Disposition of nonconforming products

|

|||

| 364 | 8.9.4.3 a | Submit to a new transformation products that are not acceptable for release | In order to reduce food safety hazard to an acceptable level | |

| 365 | 8.9.4.3 b | Redirect for other use products that are not acceptable for release | As long as food safety in the food chain is not affected | |

| 366 | 8.9.4.3 c | Destroy or dispose products that are not acceptable for release | As waste | |

| 367 | 8.9.4.3 | Retain the disposition of nonconforming products as documented information | Including the person with approving authority, cf. sub-clause 7.5 | |

| 8.9.5 |

Withdrawal or recall

|

|||

| 368 | 8.9.5 | Ensure the timely withdrawal or recall of any lot identified as potentially unsafe | By appointing a person having the authority to initiate and carry out the withdrawal or recall | |

| 369 | 8.9.5 a | Maintain documented information for | Notify stakeholders (authorities, customers, consumers), cf. sub-clause 7.5 | |

| 370 | 8.9.5 b | Maintain documented information for | Handling withdrawn, recalled or still in stock products, cf. sub-clause 7.5 | |

| 371 | 8.9.5 c | Maintain documented information for | Performing actions to be taken, cf. sub-clause 7.5 | |

| 372 | 8.9.5 | Secure products withdrawn, recalled or still in stock | Until they are managed in accordance with sub-clause 8.9.4.3 | |

| 373 | 8.9.5 | Retain the cause, extent and result of a withdrawal and recall as documented information | Cf. sub-clause 7.5 | |

| 374 | 8.9.5 | Report withdrawal and recall information as input to the management review | Cf. sub-clause 9.3 | |

| 375 | 8.9.5 | Verify the implementation and effectiveness of withdrawals and recalls through the use of appropriate techniques | Such as simulations or pratical test | |

| 376 | 8.9.5 | Retain the verification of the implementation and effectiveness of withdrawals and recalls as documented information | Cf. sub-clause 7.5 | |

| 9 |

Performance evaluation

|

Check | ||

| 9.1 |

Monitoring, measurement, analysis and performance evaluation

|

|||

| 9.1.1 |

General

|

|||

| 377 | 9.1.1 a | Determine what needs to be inspected (monitored and measured) |

"If you can't measure it, you can't manage it. Peter Drucker" |

|

| 378 | 9.1.1 b | Determine the methods for inspection, analysis and evaluation | In order to ensure valid results | |

| 379 | 9.1.1 c | Determine when to inspect | At essential steps or following a customer request | |

| 380 | 9.1.1 d | Determine when to analyze and evaluate the results of inspection | When it brings added value | |

| 381 | 9.1.1 e | Determine who shall analyze and evaluate the results of inspection | Responsibilities and authorities, cf. sub-clause 5.3 | |

| 382 | 9.1.1 | Retain inspection results as documented information | Cf. sub-clause 7.5 | |

| 383 | 9.1.1 | Evaluate the performance and effectiveness of the FSMS | In order to guarantee safe food at all times | |

| 9.1.2 |

Analysis and evaluation

|

|||

| 384 | 9.1.2 | Analyze and evaluate the results of monitoring and measurement | Including the results of verification activities related to PRPs and the hazard control plan and audits, cf. sub-clauses 8.8, 8.5.4 and 9.2 | |

| 385 | 9.1.2 a | Confirm that the overall performance of the organization meets the FSMS requirements | By conducting an analysis of the management system | |

| 386 | 9.1.2 b | Identify the need for updating or improving the FSMS | By conducting an analysis of the management system, cf. sub-clauses 10.2 and 10.3 | |

| 387 | 9.1.2 c | Identify rate trends of potentially unsafe products or process failures | By conducting an analysis of the management system | |

| 388 | 9.1.2 d | Plan the audit program related to the status and importance of areas to be audited | By conducting an analysis of the management system | |

| 389 | 9.1.2 e | Provide evidence that corrections and corrective actions are effective | By conducting an analysis of the management system | |

| 390 | 9.1.2 | Retain the results of the analysis and the resulting activities as documented information | Cf. sub-clause 7.5 | |

| 391 | 9.1.2 | Report the results as input to the management review and the updating of the FSMS | Cf. sub-clauses 9.3 and 10.3 | |

| 9.2 |

Internal audit

|

|||

| 392 | 9.2.1 a 1 | Conduct regularly planned internal audits | In order to determine whether the FSMS conforms to the internal requirements of the organization. Cf. ISO 19011 | |

| 393 | 9.2.1 a 2 | Conduct regularly planned internal audits | In order to determine whether the FSMS conforms to the requirements of ISO 22000 | |

| 394 | 9.2.1 b | Conduct regularly planned internal audits | In order to determine whether the FSMS is effective and updated | |

| 395 | 9.2.2 a | Plan, establish, implement and update an internal audit program | Including the frequency, methods, responsibilities, planning requirements (audit program) and the requirements for reporting (audit report) | |

| 396 | 9.2.2 a | Take into account in the audit program the importance of the processes concerned |

Essential points such as:

"The quality control should verify the process, not the product. Edwards Deming" |

|

| 397 | 9.2.2 b | Define the audit criteria | Define the scope of the audit; use defined and known audit criteria | |

| 398 | 9.2.2 c | Select auditors | Do not audit your own department. "No-one is a judge in his own case. Latin proverb" | |

| 399 | 9.2.2 d | Ensure that the results of the audits are communicated to the food safe team and top management | Cf. sub-clause 7.4 | |

| 400 | 9.2.2 e | Retain documented information on the application of the audit program and audit results | Cf. sub-clause 7.5 | |

| 401 | 9.2.2 f | Undertake corrections quickly and corrective actions, if necessary | Cf. sub-clauses 8.9.2 and 8.9.3 | |

| 402 | 9.2.2 g | Determine if the FSMS meets the food safety policy and objectives | Cf. sub-clauses 5.2 and 6.2 | |

| 9.3 |

Management review

|

|||

| 9.3.1 |

General

|

|||

| 403 | 9.3.1 | Review the FSMS at least once a year | In order to confirm its suitability, adequacy and effectiveness. "No system is perfect" | |

| 9.3.2 |

Management review input

|

|||

| 404 | 9.3.2 a | Conduct management review | Considering the status of actions from previous management reviews | |

| 405 | 9.3.2 b | Conduct management review | Considering changes in external and internal issues of the FSMS, including changes in the organization and its context | |

| 406 | 9.3.2 c 1 | Take into account information on the performance and the effectiveness of the FSMS and trends | On update of the FSMS, cf. sub-clauses 4.4 and 10.3 | |

| 407 | 9.3.2 c 2 | Take into account information on the performance and the effectiveness of the FSMS and trends | Results of inspection, cf. sub-clause 9.1 | |

| 408 | 9.3.2 c 3 | Take into account information on the performance and the effectiveness of the FSMS and trends | Results of verification of PRPs and the hazard control plan, cf. sub-clause 8.8.2 | |

| 409 | 9.3.2 c 4 | Take into account information on the performance and the effectiveness of the FSMS and trends | Nonconformities and corrective actions, cf. sub-clauses 8.9.2 and 8.9.3 | |

| 410 | 9.3.2 c 5 | Take into account information on the performance and the effectiveness of the FSMS and trends | Audit results, cf. sub-clause 9.2 | |

| 411 | 9.3.2 c 6 | Take into account information on the performance and the effectiveness of the FSMS and trends | Regulatory and customer inspections | |

| 412 | 9.3.2 c 7 | Take into account information on the performance and the effectiveness of the FSMS and trends | The performance of external providers, cf. sub-clause 7.1.6 | |

| 413 | 9.3.2 c 8 | Take into account information on the performance and the effectiveness of the FSMS and trends | The review of risks, cf. sub-clause 6.1 | |

| 414 | 9.3.2 c 9 | Take into account information on the performance and the effectiveness of the FSMS and trends | The extent to which objectives of the FSMS are met, cf. sub-clause 6.2 | |

| 415 | 9.3.2 d | Take into account the resources | The adequacy of resources, cf. sub-clause 7.1 | |

| 416 | 9.3.2 e | Take into account any emergency situation, withdrawal or recall | Including incidents, cf. sub-clauses 8.4.2 and 8.9.5 | |

| 417 | 9.3.2 f | Take into account feedback from external or internal origin | Including complaints, cf. sub-clauses 7.4.2 and 7.4.3 | |

| 418 | 9.3.2 g | Take into account opportunities for improvement | Continual improvement, cf. sub-clause 10.2 | |

| 419 | 9.3.2 | Present this data in a manner that enables top management to associate it with food safety objectives | Cf. sub-clause 6.2 | |

| 9.3.3 |

Management review output

|

|||

| 420 | 9.3.3 a | Include in the output of the management review decisions and actions related to continual improvement opportunities | Cf. sub-clause 10.2 | |

| 421 | 9.3.3 b | Include in the output of the management review decisions related to any need for changes to the FSMS | Such as resources, fod safety policy and objectives, cf. sub-clauses 7.1, 5.2 and 6.2 | |

| 422 | 9.3.3 | Retain the results of the management review as documented information | Cf. sub-clause 7.5 | |

| 10 |

Improvement

|

Act | ||

| 10.1 |

Nonconformities

|

|||

| 423 | 10.1.1 a 1 | React to the nonconformities | By controlling it and correcting it. "Where there is a problem, there is potential for improvement. Masaaki Imai" | |

| 424 | 10.1.1 a 2 | React to the nonconformities | By dealing with the consequences | |

| 425 | 10.1.1 b 1 | Evaluate the need for action to eliminate the root causes | By reviewing the nonconformity | |

| 426 | 10.1.1 b 2 | Evaluate the need for action to eliminate the root causes | By researching and analyzing the root causes of nonconformity | |

| 427 | 10.1.1 b 3 | Evaluate the need for action to eliminate the root causes | By researching similar nonconformity of the past or the future | |

| 428 | 10.1.1 c | Undertake any action needed | In order to treat the nonconformity | |

| 429 | 10.1.1 d | Review the effectiveness of corrective actions | in order to verify whether the action is completed | |

| 430 | 10.1.1 e | Make changes to the FSMS | If necessary | |

| 431 | 10.1.1 | React proportionally to the consequences of nonconformities | Do not go overboard on quality | |

| 432 | 10.1.2 a | Retain evidence of the nature of the nonconformities as documented information | Cf. sub-clause 7.5 | |

| 433 | 10.1.2 b | Retain the results of action as documented information | Cf. sub-clause 7.5 | |

| 10.2 |

Continual improvement

|

|||

| 434 | 10.2 | Improve continually the performance of the FSMS | By finding improvement opportunities | |

| 435 | 10.2 | Ensure continual improvement of the effectiveness of the FSMS through communication | Cf. sub-clause 7.4 | |

| 436 | 10.2 | Ensure continual improvement of the effectiveness of the FSMS through management review | Cf. sub-clause 9.3 | |

| 437 | 10.2 | Ensure continual improvement of the effectiveness of the FSMS through internal audit | Cf. sub-clause 9.2 | |

| 438 | 10.2 | Ensure continual improvement of the effectiveness of the FSMS through analysis of results of verification activities | Cf. sub-clause 8.8.2 | |

| 439 | 10.2 | Ensure continual improvement of the effectiveness of the FSMS through validation of control measures | Cf. sub-clause 8.5.3 | |

| 440 | 10.2 | Ensure continual improvement of the effectiveness of the FSMS through correctives actions | Cf. sub-clause 8.9.3 | |

| 441 | 10.2 | Ensure continual improvement of the effectiveness of the FSMS through FSMS updating | Cf. sub-clause 10.3 | |

| 10.3 |

Update of the FSMS

|

|||

| 442 | 10.3 | Ensure that the FSMS is updated | Permanently | |

| 443 | 10.3 | Evaluate the FSMS at planned intervals | By the food safety team | |

| 444 | 10.3 | Evaluate the need to review the hazard analysis | Cf. sub-clause 8.5.2 | |

| 445 | 10.3 | Evaluate the need to review the hazard control plan | Cf. sub-clause 8.5.4 | |

| 446 | 10.3 | Evaluate the need to review the PRPs | Cf. sub-clause 8.2 | |

| 447 | 10.3 a | Base updating activities on communication | Cf. sub-clause 7.4 | |

| 448 | 10.3 b | Base updating activities on any othe information | In relation with the suitability, adequacy and effectiveness | |

| 449 | 10.3 c | Base updating activities on results of verification activities | Cf. sub-clause 9.1.2 | |

| 450 | 10.3 d | Base updating activities on decisions from management review | Cf. sub-clause 9.3 | |

| 451 | 10.3 | Retain system updating activities as documented information | Cf. sub-clause 7.5 | |

| 452 | 10.3 | Report system updating activities as input to the management review | Cf. sub-clause 9.3 | |

|

|

||||